HONPINE Harmonic Robot Joint Actuator — Leading the Industry with Four Core Advantages

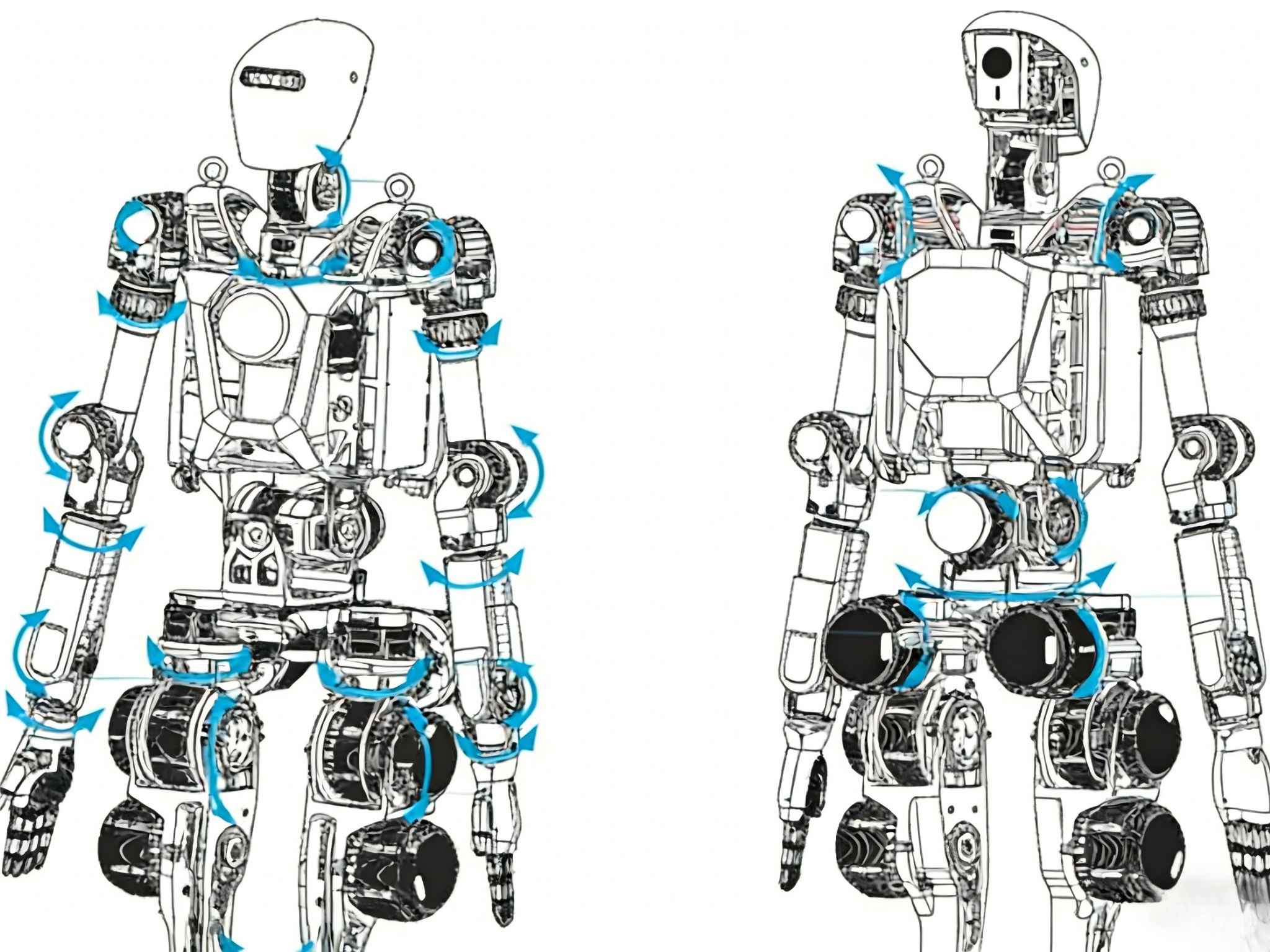

As the robotics industry continues to evolve at high speed, the robot joint actuator, known as the “power core” of robots, directly determines a machine’s motion precision, load capacity, and application range.Leveraging the unique benefits of harmonic drive technology, it has become the preferred solution for high-end robotic joints.HONPINE’s Harmonic Robot Joint Actuator, through technological innovation and integrated design, achieves breakthroughs in four key dimensions — precision, torque, operation & maintenance, and adaptability — providing an optimized solution for collaborative robots, humanoid robots, and other advanced automation systems.

1,Arcsecond-Level Precision — Redefining Motion Control Boundaries

At its core lies an ultra-thin flexible gear technology.By using specialized materials and high-precision machining, the flexspline’s thickness is reduced to the millimeter scale, achieving ±10 arcseconds of transmission accuracy.The precisely matched wave generator and flexspline design delivers zero-backlash motion, ensuring smooth response during rapid start-stop or direction changes.Its repeatability reaches 0.05 mm, fully meeting the demanding requirements of automotive precision welding, vascular suturing, and other ultra-fine motion applications.

2,High Torque Density — Compact Size, Massive Power

A custom brushless torque motor with optimized winding and magnetic circuit design boosts power density by 30% compared to the industry standard.For larger models, despite an outer diameter of less than 200 mm, the actuator achieves a peak torque exceeding 500 N·m and a rated torque up to 363 N·m, while weighing only a few kilograms.This “small size, big power” advantage allows robots to handle heavy payloads or perform high-load operations with remarkable stability and agility.

3,Integrated Design — Smarter Deployment and Maintenance

The actuator adopts a drive-control integrated architecture, deeply combining the harmonic reducer, servo motor, encoder, and torque sensor, while supporting a hollow-through design for easier cable routing.The built-in non-contact torque sensor achieves ±0.5% FS force control accuracy, and with the adaptive FOC algorithm, it dynamically adjusts parameters to maintain smooth motion even under complex loads.Its modular structure allows for simple assembly or disassembly with basic tools, extending the maintenance cycle beyond 10,000 hours and significantly reducing operational costs for enterprises.

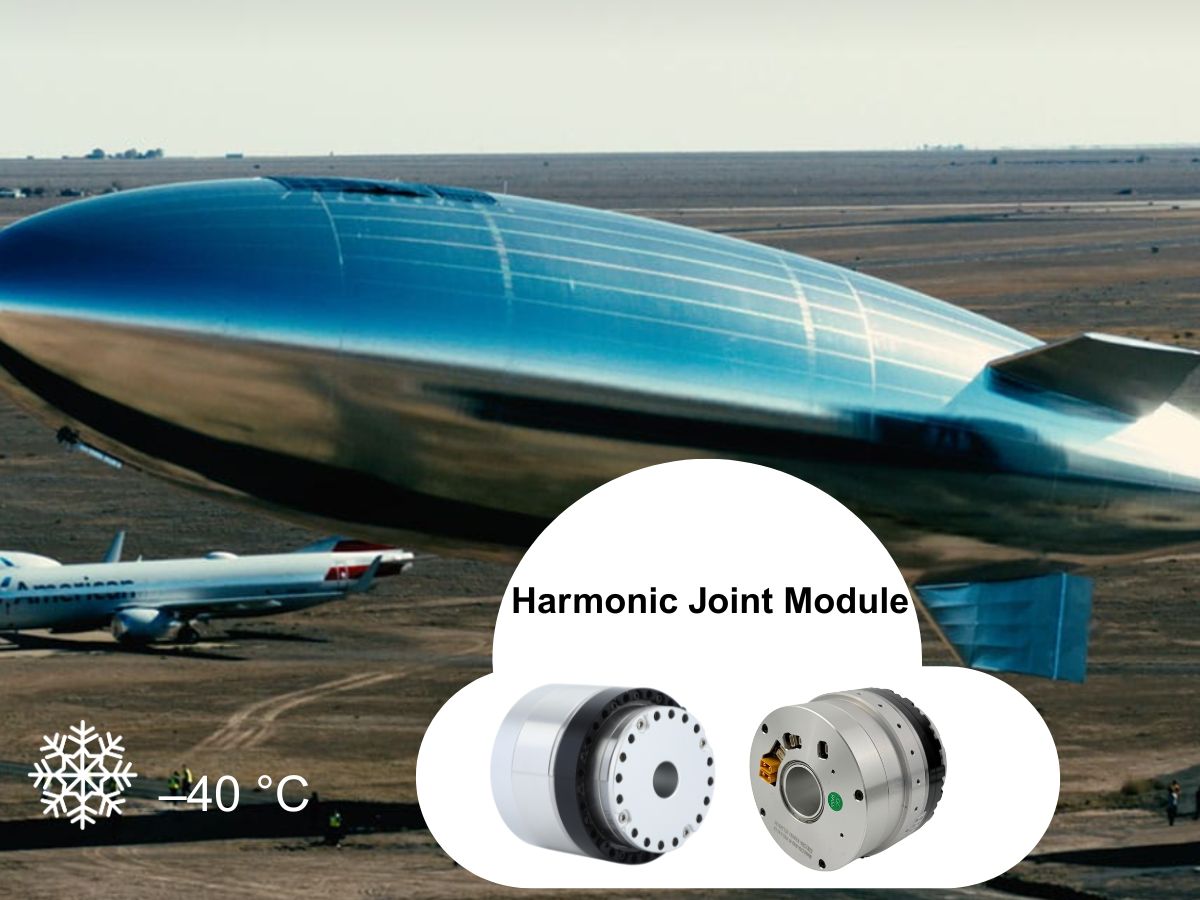

4,All-Scenario Adaptability — Maximum Reliability

With an IP50 and above protection rating, the actuator provides dustproof and water-resistant performance, suitable for industrial workshop environments, household service conditions, and other demanding scenarios.From lightweight 2.6 kg modules to high-torque models, HONPINE’s range covers collaborative robots, humanoid robots, and rehabilitation exoskeletons.It also supports ROS, Python, and other mainstream software interfaces, allowing for rapid integration without additional adaptation — truly a universal robotic joint core.

From micron-level precision tasks to heavy-load operations, and from efficient maintenance to multi-environment adaptability,HONPINE’s Harmonic Robot Joint Actuator delivers comprehensive performance advantages, providing a key foundation for the next wave of robotic innovation.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand