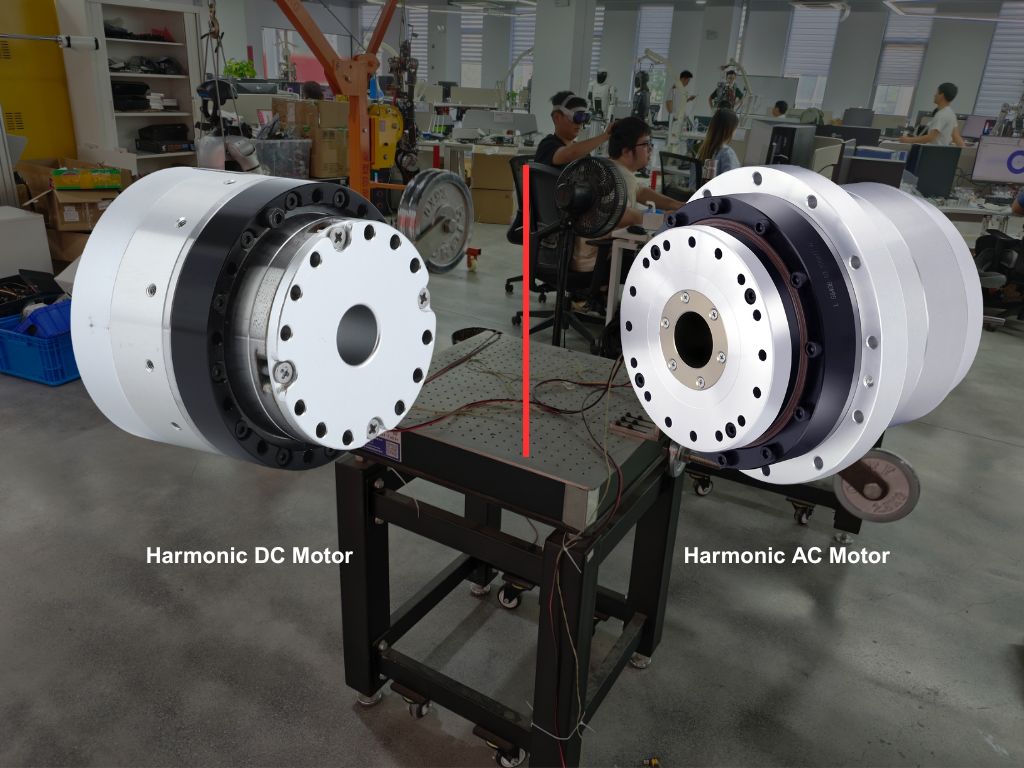

Position-Mode Calculation Logic for Single-Encoder and Dual-Encoder Harmonic Joint Modules

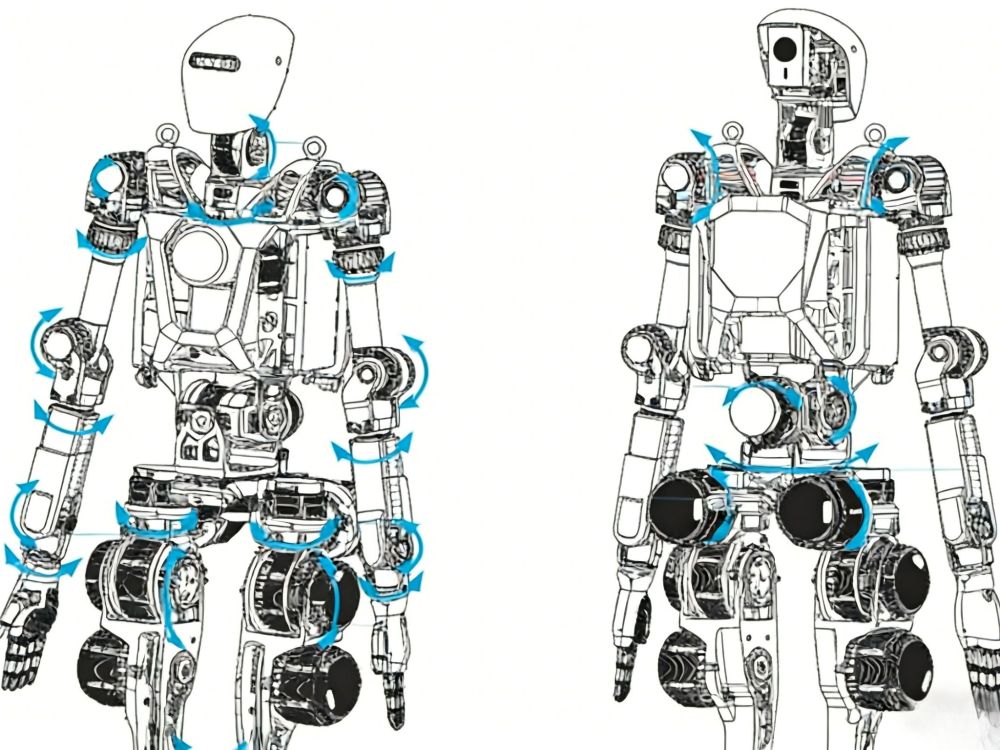

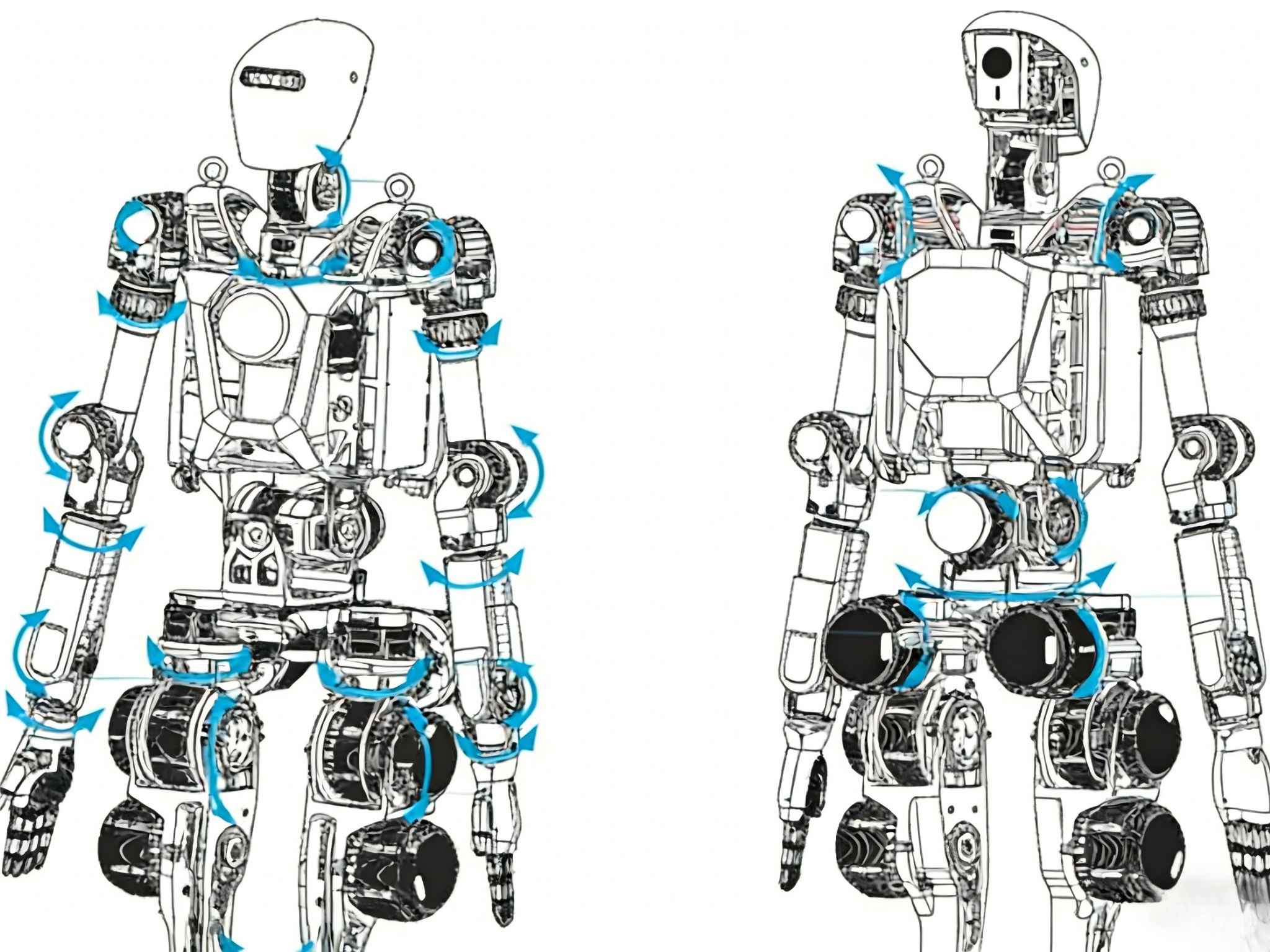

In the core hardware of robotics, the position-control accuracy of harmonic joint modules directly affects overall system performance. Understanding how position mode computes motion is essential for precise module control. Today, let’s break down the calculation logic for single-encoder and dual-encoder motors, as well as the key points of speed control.

Single-Encoder Motor Position Calculation

Single-encoder motors typically use a 16-bit resolution. The calculation must take the actual gear reduction ratio into account.

A 16-bit resolution means one mechanical revolution of the motor corresponds to 65,536 pulses. To obtain the number of pulses for one revolution at the output shaft, multiply this value by the reduction ratio.

For example, with a commonly used 121:1 reduction ratio, one revolution of the output shaft requires:

65,536 × 121 = 7,929,856 pulses

This value directly determines the base accuracy for position control in a single-encoder motor.

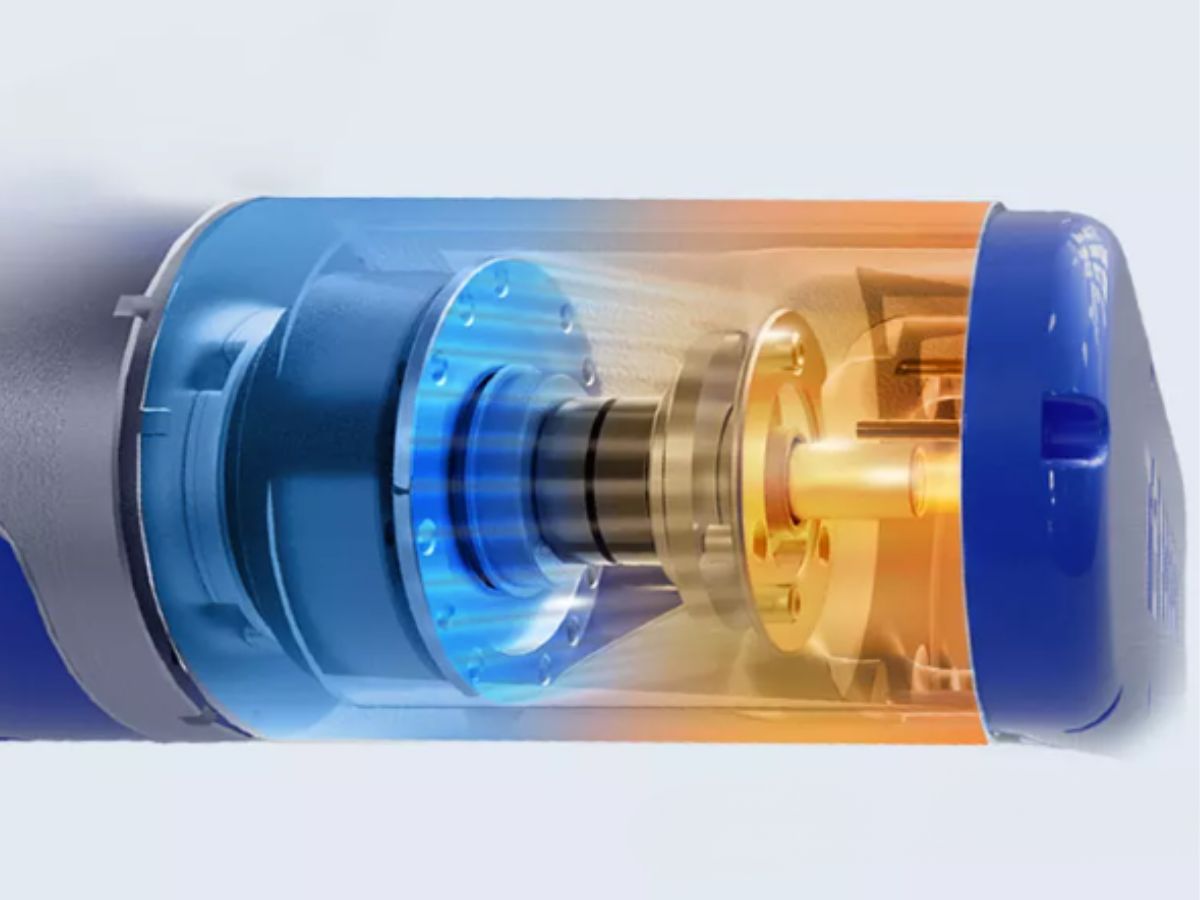

Dual-Encoder Motor Position Calculation

Dual-encoder motors use an 18-bit resolution and do not require the reduction ratio in the calculation.

An 18-bit encoder produces 262,144 pulses per revolution, meaning that when the pulse count reaches 262,144, the output shaft completes one full revolution. This eliminates the reduction-ratio conversion step, making operation more convenient.

Speed Control Logic

Speed control is equally important. In position-control mode, speed is derived from the change in commanded position over time, and the system internally limits the maximum motor speed.

This maximum speed can be configured through SDO parameter 0x6080, with a default value of 1200 RPM.

If you need the actual output-shaft speed, you must convert it using the motor’s reduction ratio to ensure the speed matches real-world application requirements.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand