The Role of Harmonic Drive Gears in Achieving 5–10 μm Accuracy in Dental Milling Machines

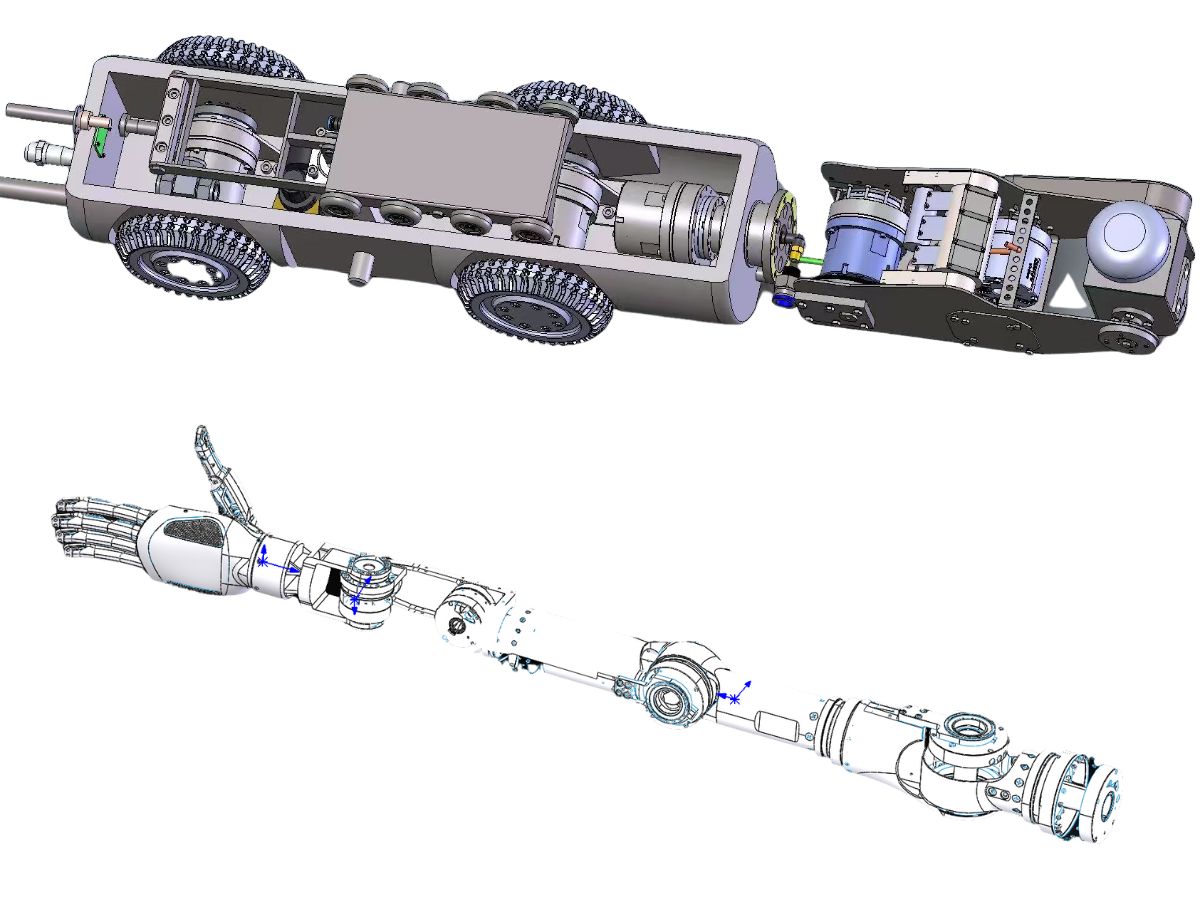

A dental milling machine is a CNC machining system used to directly process digital dental models into restorations such as crowns, bridges, veneers, inlays, and implant abutments. Dental milling machines require far higher operational accuracy and motion stability than ordinary equipment. This article explains how harmonic drive gear help dental milling machines achieve stable, continuous, and controllable operation.

Why do dental milling machines place especially high demands on transmission components?

Dental milling machines process materials such as resin, zirconia, and cobalt-chromium alloys. The surfaces are complex, the edges are extremely fine, and tolerance requirements are typically 5–10 μm. In essence, a dental milling machine is a compact, high-precision, multi-axis CNC machine tool. Dental restorations demand extremely high dimensional accuracy—any deviation, whether too large or too small, can result in poor fit. Even slight vibration may cause edge chipping or surface damage.

Why harmonic drive gear can serve as the core transmission components of dental milling machines?

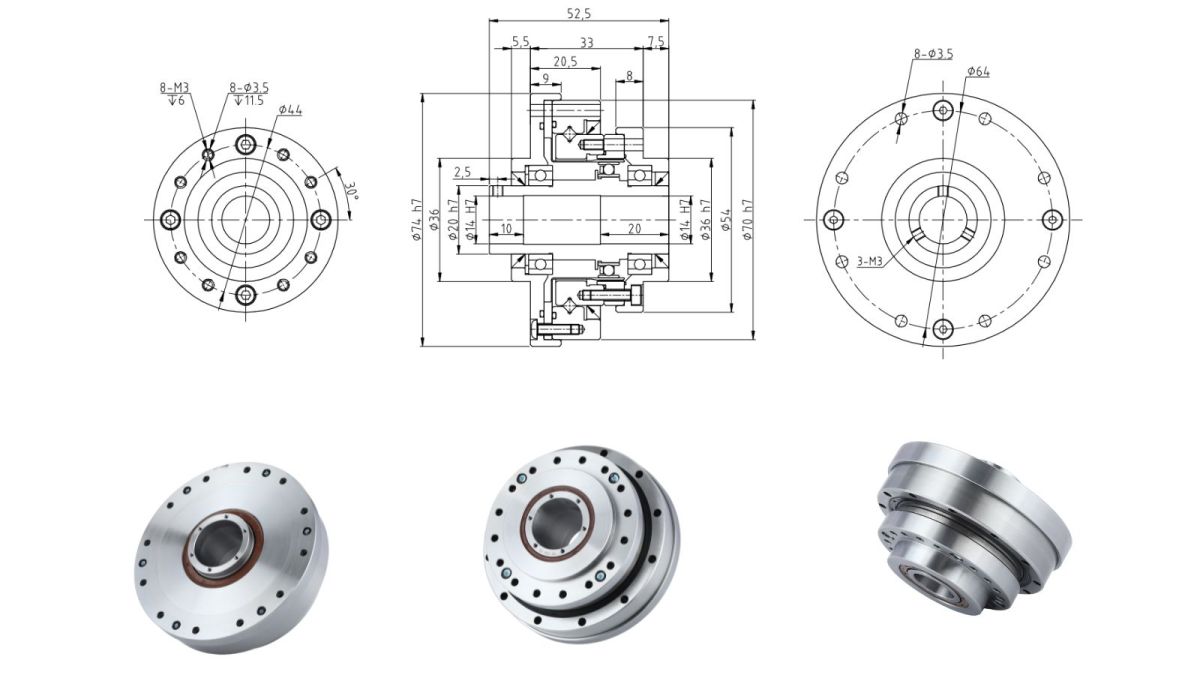

High precision and zero backlash

Harmonic drive gears operate based on elastic deformation of a flexspline. Compared with conventional gear reducers, their transmission accuracy can reach within ±10 arcseconds and they feature virtually zero backlash. This allows dental milling machines to maintain stability during extremely fine feed motions (such as 0.001 mm per step), preventing machining errors and ensuring dimensional accuracy and surface quality of dental restorations.

High rigidity for vibration suppression

When machining hard materials such as zirconia and titanium alloys, dental milling machines must withstand high-frequency cutting forces. The high torsional rigidity of harmonic drive gears (5–10 Nm/arcmin) effectively reduces vibration and improves dynamic response, enabling more accurate tool paths and preventing edge chipping or surface defects.

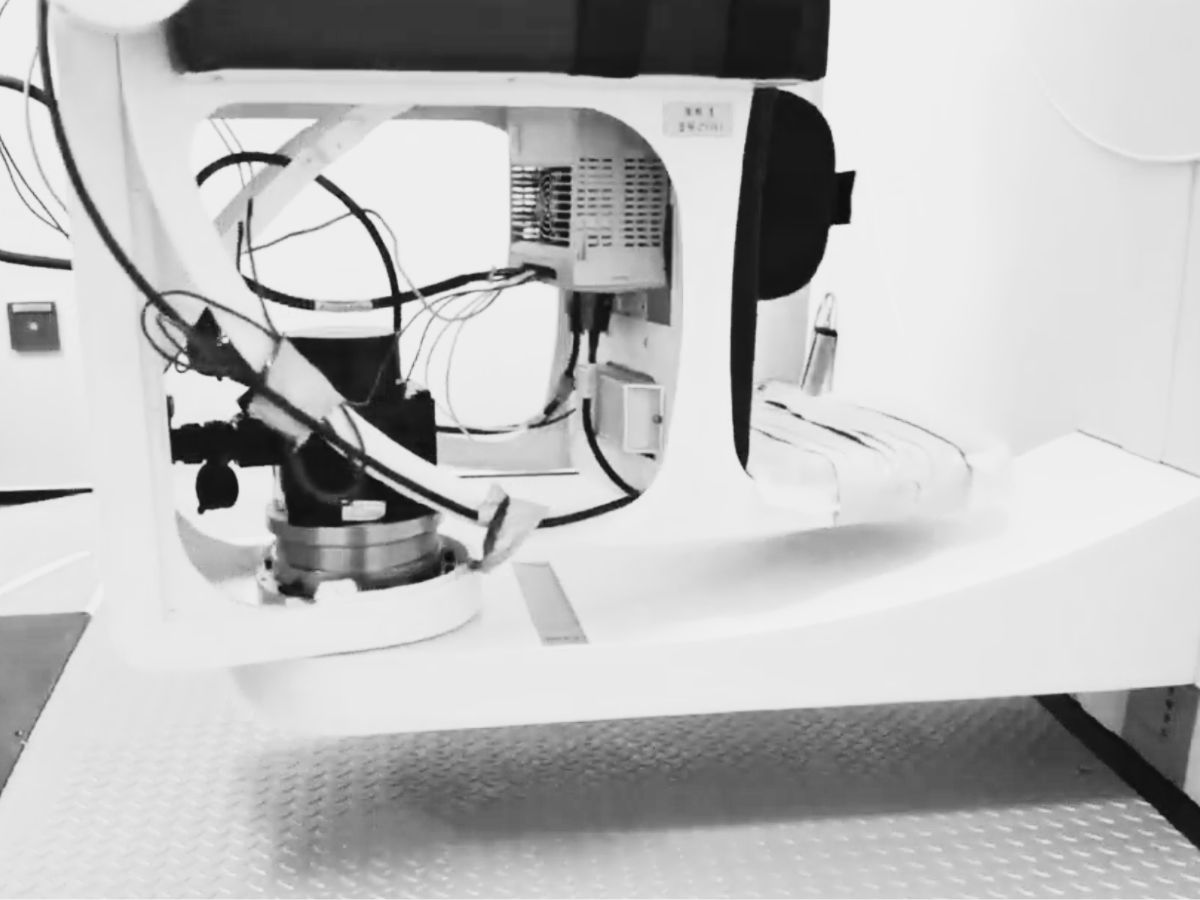

Compact structure suitable for highly integrated designs

Harmonic drive gears feature compact size and low weight, making them easy to integrate into multi-axis motion systems of dental milling machines (such as five-axis machining). They meet the requirements of complex surface processing while improving overall space utilization of the equipment.

In addition to dental milling machines, dental engraving machines and dental milling-grinding machines share the same—if not higher—dependence on smooth and stable operation. For these dental devices, harmonic reducers are irreplaceable. Contact us to provide solutions for your dental equipment.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand