Why Harmonic Drive Strain Wave Reducers Are Ideal for Flexographic Printing Machine Registration Systems?

Because the inks used in flexographic printing comply with green and environmentally friendly standards, flexographic printing has become increasingly popular in recent years as environmental awareness continues to rise. Compared with traditional printing methods, flexographic printing machines offer higher productivity and improved printing accuracy.

This article summarizes HONPINE’s experience gained from supplying harmonic drive strain wave reducers to flexographic printing machine manufacturers in recent years.

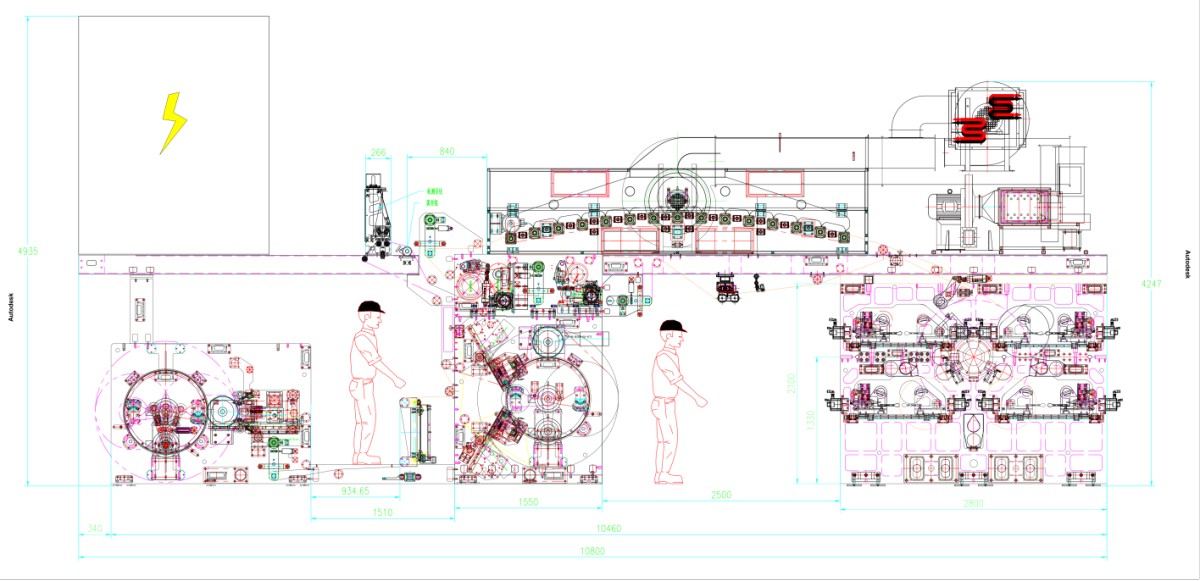

What Is a Flexographic Printing Machine?

Flexographic printing is a type of relief printing technology. Its basic working principle is as follows:

Ink from the ink chamber is transferred through the ink transfer roller and the anilox roller to the plate cylinder fitted with a photosensitive resin plate engraved with the image pattern. By adjusting the pressure between the printing cylinders of each color station, the inked image on the printing plate is transferred onto the substrate. The printing cycle is completed after drying.

Key Features of Flexographic Printing Machines

Uses non-toxic, fast-drying water-based inks, solvent-based inks, or UV inks

Suitable for a wide range of absorbent and non-absorbent substrates

Uses rubber plates or photopolymer plates with high durability

Multiple color stations, capable of printing 10 colors or more

Strong integrated processing capability, such as folding cartons and labels

High efficiency and cost-effectiveness for short-run printing

Fast job changeover and simplified pre-press preparation

Printing speeds up to 2000 feet per minute, with resolution reaching 175 lines per inch or higher

Flexographic printing operates with light printing pressure

Why Is Precision So Important in Flexographic Printing Machines?

Flexographic printing requires extremely high registration accuracy, especially in multi-color printing where precise synchronization between each plate cylinder is essential.

Misregistration is a common defect in flexographic printing. It is usually caused by inaccurate positioning of color stations, resulting in blurred or distorted images. There are many factors that can lead to misregistration.

First, consider the printing plates. Although modern film output quality is already very high and the influence of longitudinal and transverse distortion is relatively small, calibration standards vary among manufacturers. As a result, printing plates from different suppliers may not register accurately with each other, including laser-engraved plates.

Next is plate mounting. Generally, initial registration is referenced from the center alignment marks of the plate, allowing mounting adjustments to extend evenly toward both sides, reducing large errors. This requires the plate mounting machine to be properly calibrated in advance.

Why Do Flexographic Printing Machines Use Harmonic Drive Strain Wave Reducers?

Continuous Operation with Differential Transmission

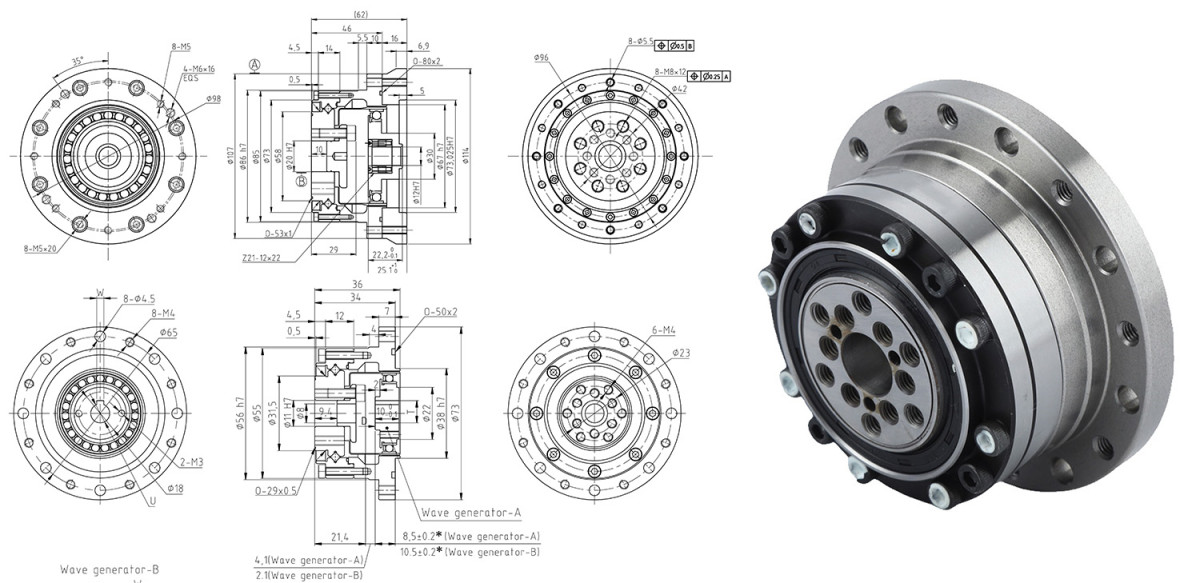

In a harmonic drive strain wave reducer, the Circular Spline serves as the main power input, while the Wave Generator provides the trim or fine-adjustment input. This structure allows phase addition or cancellation via the wave generator while the main drive continues to run, making it ideal for registration adjustment during continuous operation.

High Precision with Near-Zero Backlash

Harmonic drive strain wave reducers offer very high angular transmission accuracy and near-zero backlash, which significantly reduces registration errors, color misalignment, and ghosting effects.

High Repeatability

Flexographic printing machines typically use multi-axis servo drives, requiring extremely high synchronization between printing units. With low transmission error and excellent repeat positioning accuracy, harmonic drive strain wave reducers enable precise control of plate cylinder phase, supporting online plate adjustment and dynamic compensation.

Compact Design

Space within a flexographic printing machine is limited, particularly around the plate cylinders and anilox rollers. The compact size and lightweight design of harmonic drive strain wave reducers make them especially suitable for these applications.

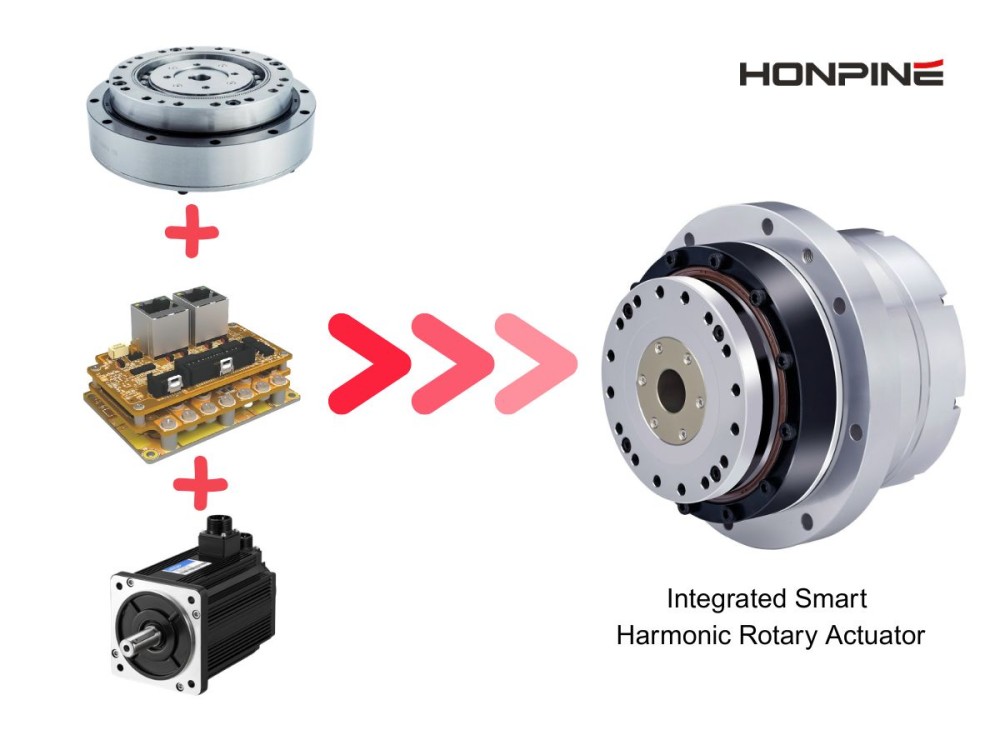

HONPINE Harmonic Drive Strain Wave Reducers

HONPINE has been manufacturing harmonic drive strain wave reducers since 2018, offering a complete range of tooth profiles and sizes, with support for customization even in small quantities.

In recent years, HONPINE harmonic drive strain wave reducers have been trialed in flexographic printing machines in the United States, Australia, and Europe, receiving very positive feedback from customers.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand