Why Are Harmonic Rotary Actuators Perfect for Medical Equipment?

Harmonic rotary actuators(typically integrated systems consisting of a harmonic drive reducer, frameless torque motor, encoder, and optional brake) are regarded as key components in medical equipment. The core reason is that they simultaneously meet the most stringent medical requirements for precision, compact size, safety, and controllability. The following explanation is structured from three perspectives: technical characteristics, application scenarios, and medical value.

The Role of the Harmonic Drive Reducer in Rotary Actuators

At the heart of a harmonic rotary actuator is the harmonic drive reducer, which is responsible for motion and power transmission with extremely high positioning accuracy. Backlash during transmission is minimal—some high-end models achieve positioning errors of ≤5 arcseconds, with backlash controlled within 1 arcminute. Repeat positioning accuracy can reach ±0.05 mm, fully meeting the demands of high-precision medical devices.

In addition, the large number of meshing teeth and high overlap ratio ensure smooth motion, low impact and vibration, and very low operating noise—critical advantages in medical environments where stability and patient comfort are essential.

Differences Between Harmonic Drive Actuators and Conventional Servo Motor + Harmonic Reducer Solutions

Compared with traditional configurations that combine a servo motor with a harmonic reducer, a harmonic drive actuator offers a highly integrated design. Overall size can be reduced by approximately two-thirds, and weight by about 50%, while still achieving high reduction ratios within extremely limited installation space.

Maintenance requirements are minimal. Transmission energy loss is low, with efficiency ranging from 69% to 96%. Wear is evenly distributed across components, ensuring reliable operation and long service life. Apart from routine lubrication, no frequent or complex maintenance is required—an important advantage for medical equipment with high uptime requirements.

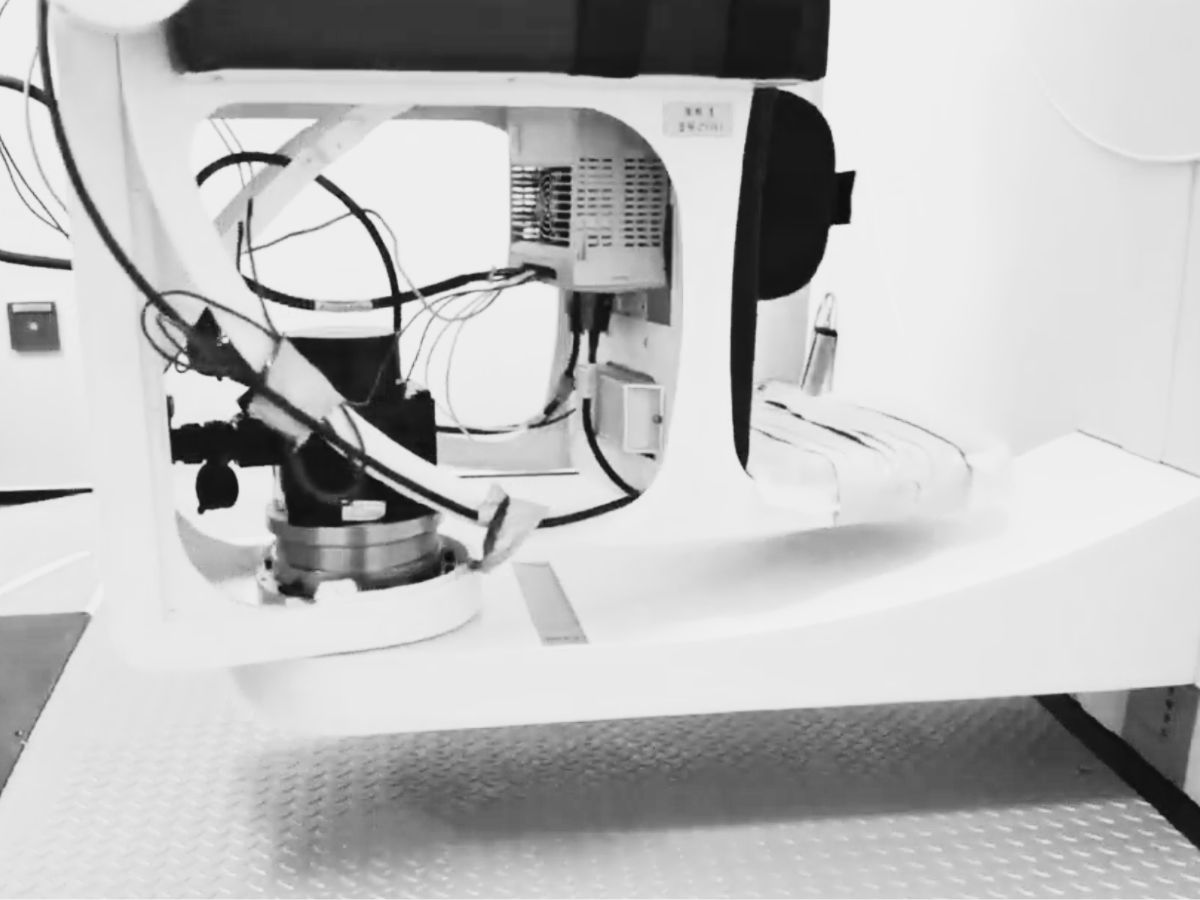

Application of Harmonic Drive Actuators in Otolith Repositioning Devices

The treatment of benign paroxysmal positional vertigo (BPPV) focuses on moving the patient’s head along precise spatial trajectories, using gravity to guide displaced otoliths back to their correct position in the inner ear. Traditionally, this procedure relies on manual manipulation by clinicians.

Electromechanical systems—often integrated with video nystagmography and, in some research or complex cases, assisted by X-ray fluoroscopy—use rotary actuators to execute these movements with high precision and repeatability. Whether in CT systems that push the limits of physical performance, or in otolith repositioning devices designed for patient-friendly and highly accurate therapy, harmonic drive actuators enable programmable, high-precision motion control.

By fundamentally enhancing motion accuracy, safety, and consistency, harmonic drive actuators significantly improve medical device performance and treatment outcomes, making them an indispensable component of modern precision medicine.

Contact us to learn more about the applications of harmonic drive actuators in medical equipment.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

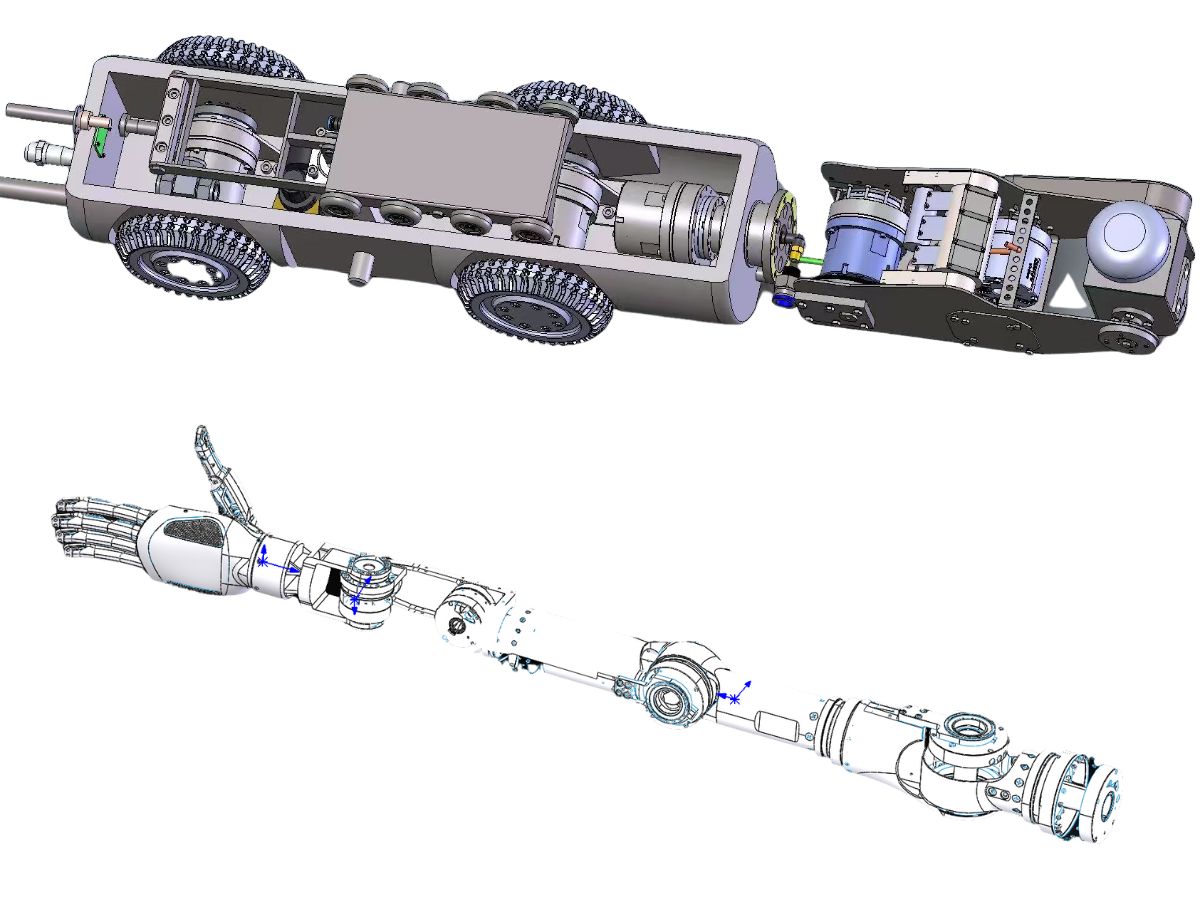

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand