Why Planetary Gear Reducers Perform Excellently in Integrated Strapping and Stretch Wrapping Machines?

Planetary gear reducers excel in integrated strapping and stretch wrapping machines primarily due to their technical characteristics: compact design, high torque, low backlash, impact resistance, and maintenance-free operation. These features allow them to precisely match the complex, multi-station operational requirements of the equipment, which include strap tightening, film carriage winding, and pallet rotation/lifting. Compared to cycloidal pinwheel reducers or standard gear reducers, planetary reducers effectively address core challenges such as limited space, alternating loads, precise positioning, and continuous operation. They also offer significant advantages in transmission efficiency, operational stability, and maintenance costs, making them well-suited for the automated, integrated strapping and wrapping needs at the end of logistics, warehousing, and production lines.

An integrated strapping and stretch wrapping machine is a pallet packaging device that combines steel/plastic strap bundling and film wrapping. Its operation involves the instantaneous tightening impact of the strapping mechanism, constant-tension winding by the film carriage, heavy-duty low-speed rotation of the pallet turntable, and precise positioning of the lifting mechanism. These working conditions demand that transmission components possess specific traits: short-duration high torque output, resistance to frequent start-stop impacts, smooth low-speed operation without jitter, and high integration within small spaces. The technical strengths of planetary reducers align perfectly with these demands, making them the preferred solution for the machine's core transmission system.

1.Adapts to Compact Multi-Mechanism Layout, Small Size Enables High Integration

The body space of an integrated strapping and stretch wrapping machine is limited, as it needs to simultaneously house structures like the strapping chamber, film carriage rails, turntable, and lifting column. The installation space for core transmission points (turntable, film carriage drive, strap tightening mechanism) is narrow and dispersed. Planetary reducers feature a coaxial design where the input and output shafts are in line. This results in significantly smaller axial/radial dimensions compared to cycloidal pinwheel or cylindrical gear reducers of equivalent torque. They can be directly integrated with servo/stepper motors without requiring extra space for transmission linkage. This allows them to be perfectly embedded into the turntable base, the side of the film carriage rails, or the small transmission chamber of the strapping mechanism. This enables a compact and lightweight overall design for the equipment, preventing a bulky or cluttered machine layout caused by an oversized reducer. Furthermore, their wide range of modular specifications (covering micro to medium/large sizes) allows for flexible selection based on the torque requirements of different mechanisms. A single machine can utilize multiple planetary reducers of different specifications to meet the specific needs of each transmission point, enhancing the overall level of integration.

2. High Torque Density + Short-Term Impact Resistance, Matches the Load Characteristics of Strapping/Wrapping

The two core operational stages of the machine place highly specific demands on torque. When the strapping mechanism tightens the pallet load, it requires an instantaneous ultra-high torque output (to overcome material gaps and achieve tight binding), which constitutes a short-duration impact load. The pallet turntable must drive the entire heavy load (weighing tens to hundreds of kilograms) for low-speed rotation, which constitutes a continuous constant-torque heavy load. The torque density of planetary reducers is far higher than that of traditional reducers, enabling high torque output from a small size. This allows them to provide the turntable with sustained heavy-load constant torque for smooth rotation, while also withstanding the instantaneous impact torque during strap tightening. They can cooperate with the motor to achieve short-duration high-power output without needing additional torque amplification mechanisms, thereby simplifying the transmission structure. Their core components (planet carrier, gears, output shaft) are made from high-strength alloy steel forgings, providing strong overall structural rigidity. This effectively absorbs the instantaneous impact loads during strapping, preventing deformation or gear tooth breakage in transmission components. This solves the frequent failure problems associated with traditional reducers due to poor impact resistance.

3. Low Backlash + High Precision, Ensures Wrapping/Positioning Quality

The core of the machine's operational quality lies in accurate strapping position, neat film overlap, and constant film carriage tension. When the film carriage travels along the rails for winding, its travel speed and position must be precisely controlled to ensure even film layer spacing. The strapping mechanism must accurately align with the pallet's binding points to avoid strap deviation. The lifting mechanism must precisely control the film carriage height to adapt to pallet loads of different heights. The precision planetary reducers used in such equipment can achieve backlash as low as under 3 arc-minutes (some micro models reach 1 arc-minute). This ensures no lost motion or hysteresis during transmission, enabling precise closed-loop control with servo motors. It achieves high-precision repeat positioning for film carriage travel, strapping location, and height adjustment. This guarantees neat film stacking and accurate strap placement, preventing quality issues like film carriage deviation, strapping misalignment, or loose wrapping caused by transmission backlash. Furthermore, the hysteresis-free transmission resulting from low backlash makes the film carriage tension adjustment more responsive. Combined with the tension control system, it enables constant tension output during the winding process, preventing film breakage or overly loose wrapping, thereby enhancing the stability of the pallet package.

4. High Stability at Low Speed, No Jitter, No Sticking

Both pallet rotation and low-speed film winding require smooth, jitter-free transmission. If sticking or jitter occurs during the transmission process, it can cause film winding wrinkles or uneven strap binding. The gears in planetary reducers undergo high-precision grinding and profile modification, resulting in uniform meshing clearance. The load-sharing structure of the planet gears allows forces to be distributed more evenly. Even at low rotational speeds, the transmission exhibits no significant impact or jitter. Their running smoothness is far superior to that of standard gear reducers, ensuring fluid film carriage winding and pallet rotation, which improves packaging appearance and quality.

5. Strong Radial/Axial Load Capacity, Adapts to Complex Loading Conditions

The core transmission points in an integrated strapping and stretch wrapping machine are not subject to pure torque loads; they are often accompanied by radial/axial loads. For example, the output shaft of the film carriage travel reducer must withstand radial loads from the carriage's own weight plus the rail friction during travel. The output shaft of the pallet turntable reducer must withstand axial loads from the gravity of the entire pallet load plus radial loads from off-center rotation. The strapping mechanism reducer must withstand alternating axial tension forces during strap tightening. Planetary reducers feature a high-precision, heavy-duty bearing group design at the output end. This enables them to simultaneously withstand high torque, radial loads, and axial loads. This eliminates the need for additional support bearings at the transmission points, simplifying the mechanical design of the equipment. It also prevents issues such as reducer shaft system deformation or seizing due to insufficient load capacity, solving the problems of easy wear and high failure rates associated with traditional reducers designed for single-load types.

6. Maintenance-Free + Long Service Life, Reduces Equipment Operating Costs

Integrated strapping and stretch wrapping machines are often deployed in logistics warehouses or at the end of production lines, where the operating environment may contain dust and oil. Maintenance personnel are typically general workshop operators who lack specialized skills in transmission component repair, placing a high demand on maintenance convenience and sealing for transmission parts. Planetary reducers use lifetime lubricating grease that requires no maintenance. This effectively prevents dust and oil from entering the reducer's interior while also avoiding grease leakage. In harsh workshop environments, they do not require frequent grease changes or disassembly for repair, significantly reducing maintenance workload.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

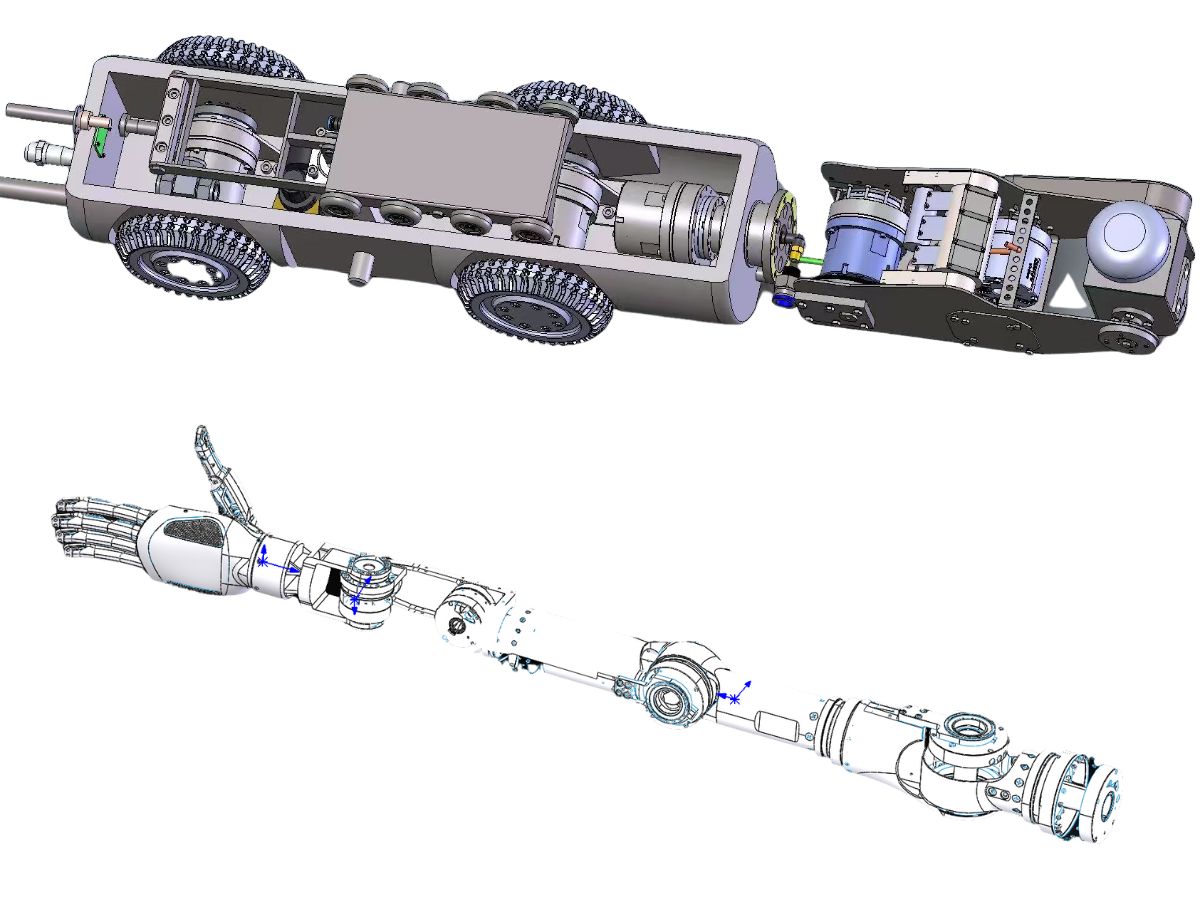

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand