How Planetary Gearboxes Enhance CNC Servo Motor and Stepper Motor Performance?

Planetary gearboxes, with their core advantages of high transmission efficiency, high torque density, high positioning accuracy, low backlash, and compact structure, have become key power transmission components in CNC equipment. Their primary function is to convert the high-speed, low-torque output of servo motors or stepper motors into low-speed, high-torque output, while ensuring transmission accuracy and stability, thereby meeting the stringent requirements of CNC machine tools for motion control, positioning accuracy, and load capacity.

Why Planetary Gearboxes Are Ideal for CNC Machine Tools?

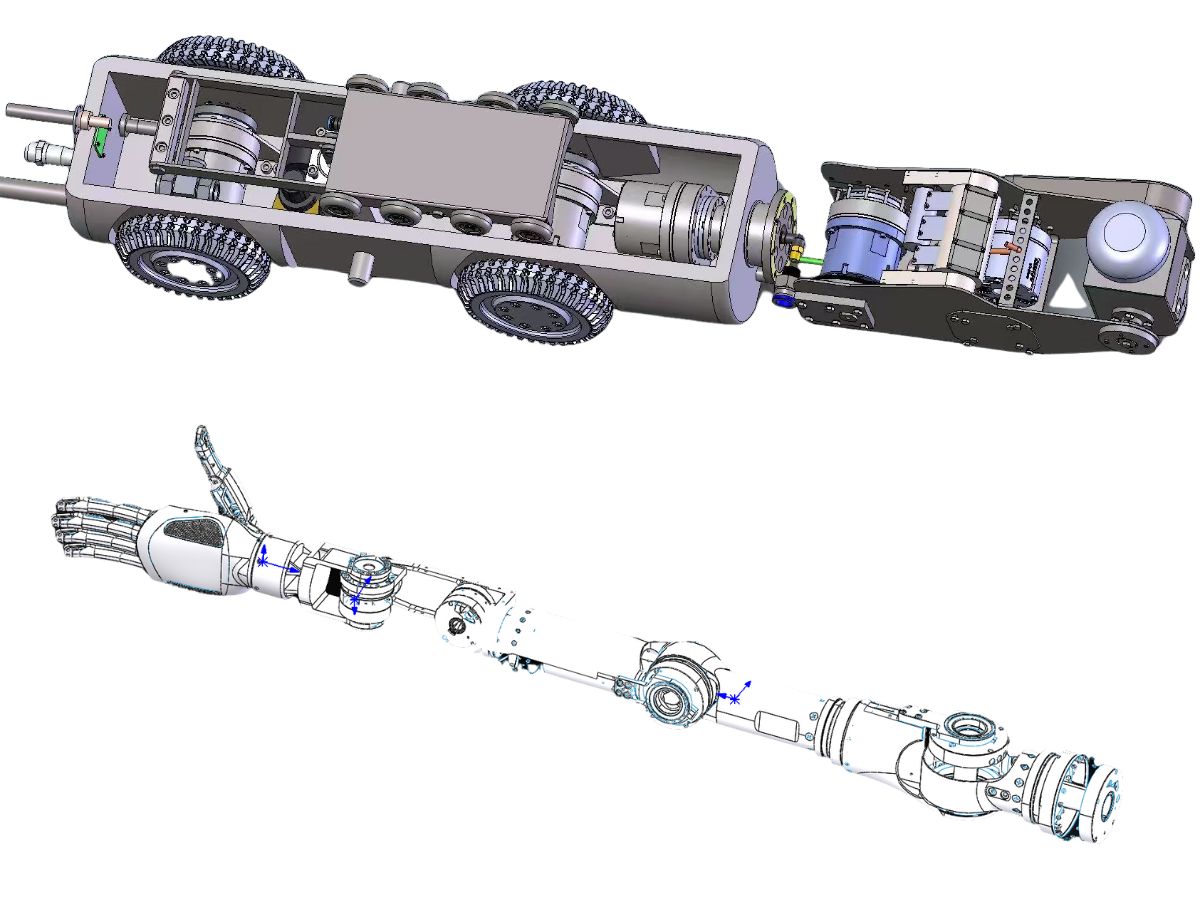

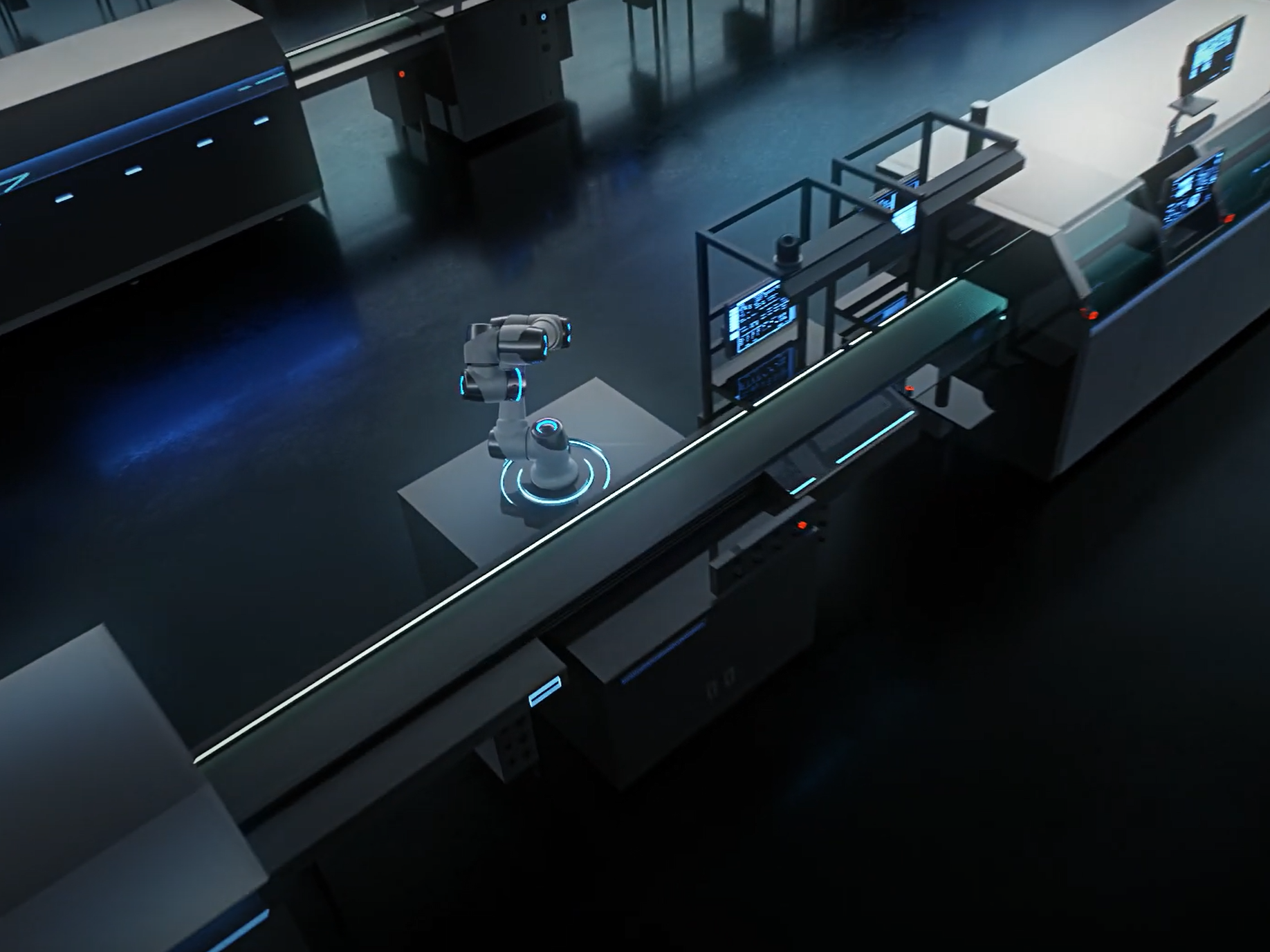

The core demands of the CNC industry—high-precision machining, high dynamic response, long-term stable operation, and heavy-load drive capability—are highly aligned with the technical characteristics of planetary gearboxes. Their applications cover critical motion units of CNC machine tools, including feed axes, spindles, rotary tables, and tool magazines / automatic tool changers (ATC). Planetary gearboxes are essential foundational components for achieving high precision, high rigidity, and high reliability in CNC machining systems.

Role of Planetary Gearboxes in CNC Machine Tools

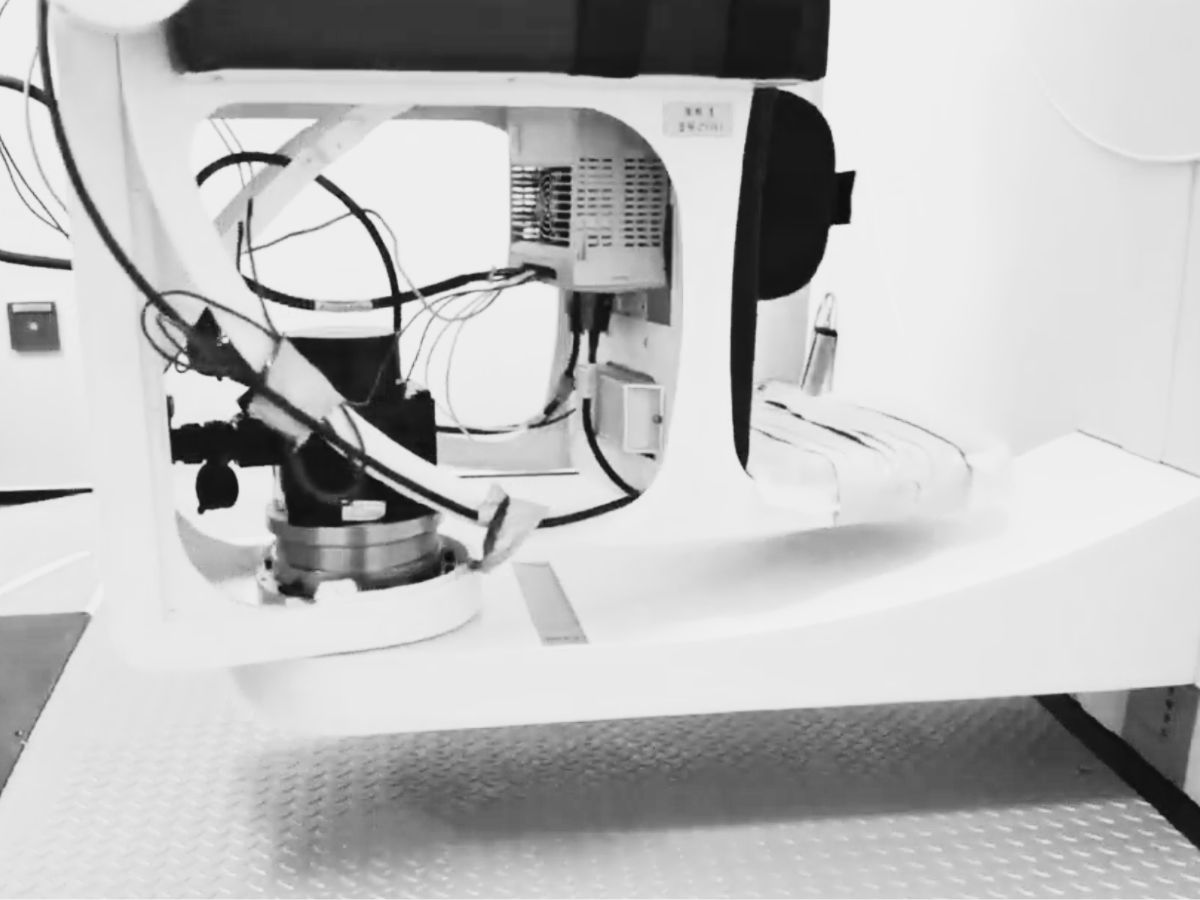

The X/Y/Z linear feed axes of CNC machine tools are the core systems for precise control of machining paths. The mainstream transmission solution adopts a servo motor + planetary gearbox + ball screw / linear guideway configuration, while some heavy-duty CNC equipment additionally employs rack-and-pinion drive systems.

In CNC machine tools, planetary gearboxes perform the following key functions

Amplifying servo motor output torque to meet the torque requirements of feed axes during rapid acceleration and deceleration, high-speed feeding, and heavy-load cutting, making them suitable for heavy cutting and deep-hole machining applications;

Reducing motor speed to match the optimal operating speed of ball screws or rack-and-pinion systems, preventing screw resonance at high speeds and minimizing gear tooth wear, thereby improving transmission smoothness;

Ensuring low backlash (precision planetary gearboxes can achieve ≤3 arcmin, and ultra-precision models ≤1 arcmin), guaranteeing the positioning accuracy and repeatability of feed axes, and meeting micron-level tolerance requirements for CNC machining, such as precision mold manufacturing and aerospace component processing.

Planetary gearboxes are suitable for virtually all CNC equipment with linear feed systems, including CNC lathes, machining centers, gantry milling machines, CNC grinding machines, and CNC drilling machines. With their characteristics of high precision, high rigidity, high dynamic response, and compact size, planetary gearboxes are perfectly matched to the performance requirements of CNC machine tools.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand