Why HONPINE Harmonic Servo Actuators Are Transforming Medical Robotics

Medical robots are automated robotic systems used in the medical field to assist, enhance, or replace doctors, nurses, and other medical equipment in performing diagnosis, surgery, rehabilitation, patient care, and auxiliary treatments. They integrate robotics, artificial intelligence, sensing technology, mechatronics, and computer control systems to improve medical precision, efficiency, safety, and the overall patient experience.This article explains why the HONPINE Harmonic Servo Actuator is highly suitable for medical robotics.

Medical Robot Categories

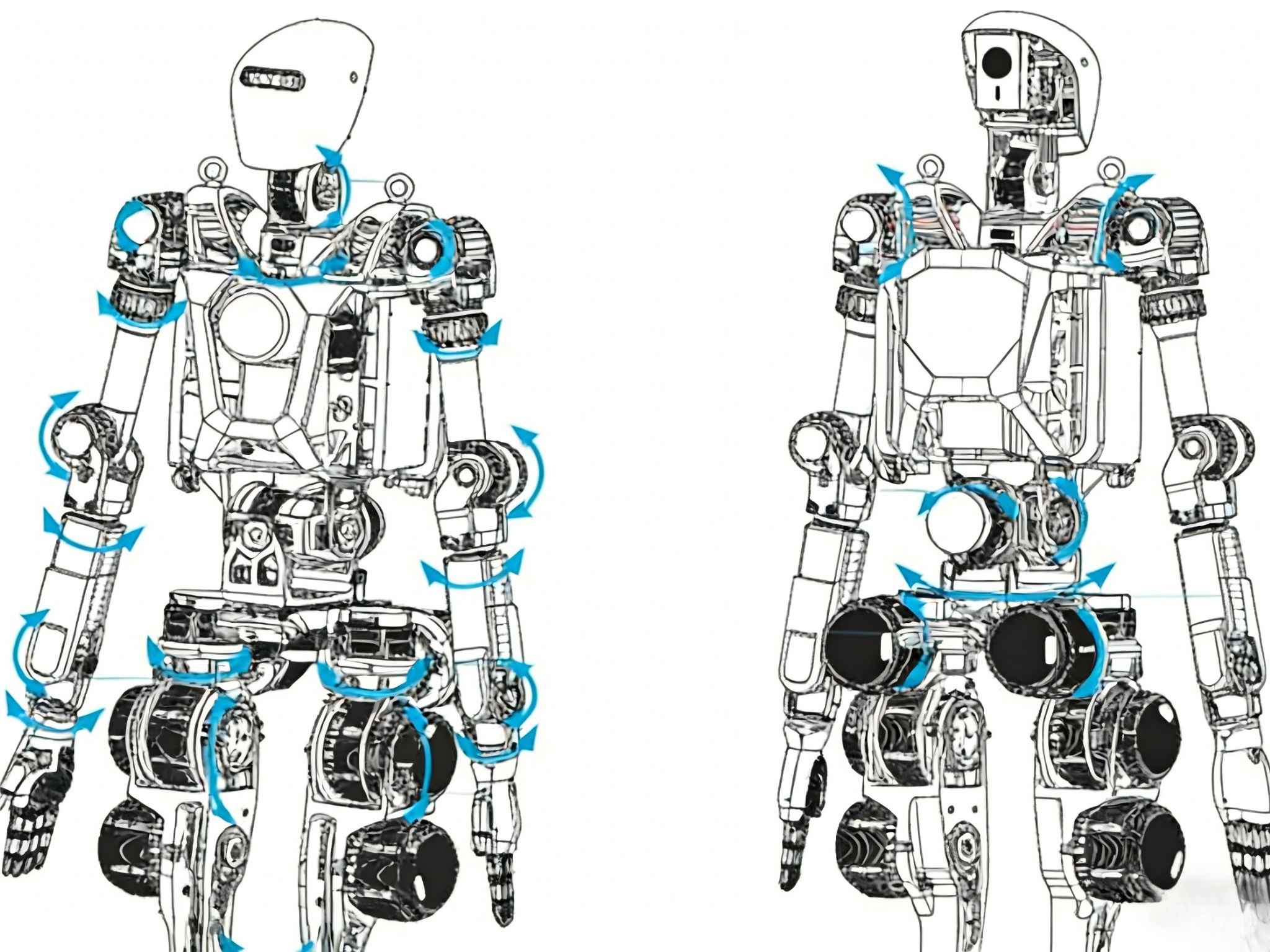

Medical robots include surgical robots, rehabilitation and assistive robots, diagnostic and laboratory robots, nursing and service robots, and robotic platforms for minimally invasive and optical procedures.

Even within surgical robots alone, there are laparoscopic robots, orthopedic robots, natural-orifice surgery robots, vascular surgery robots, percutaneous puncture robots, and neurosurgical robots.

Despite their variety, their core characteristics remain the same:high precision, safety and reliability, and human-friendly interaction.

Current Status of Medical Robots

Medical robots have extremely high technical barriers and complex entry requirements. Surgical robots require multidisciplinary integration, making independent R&D challenging.

Their core components—mechanical arms, optical tracking systems, servo motors, reducers, and controllers—have high technological content, long development cycles, and require extensive investment.

Furthermore, surgical robots feature highly complex structures that demand advanced manufacturing processes and premium materials to ensure stability and reliability.

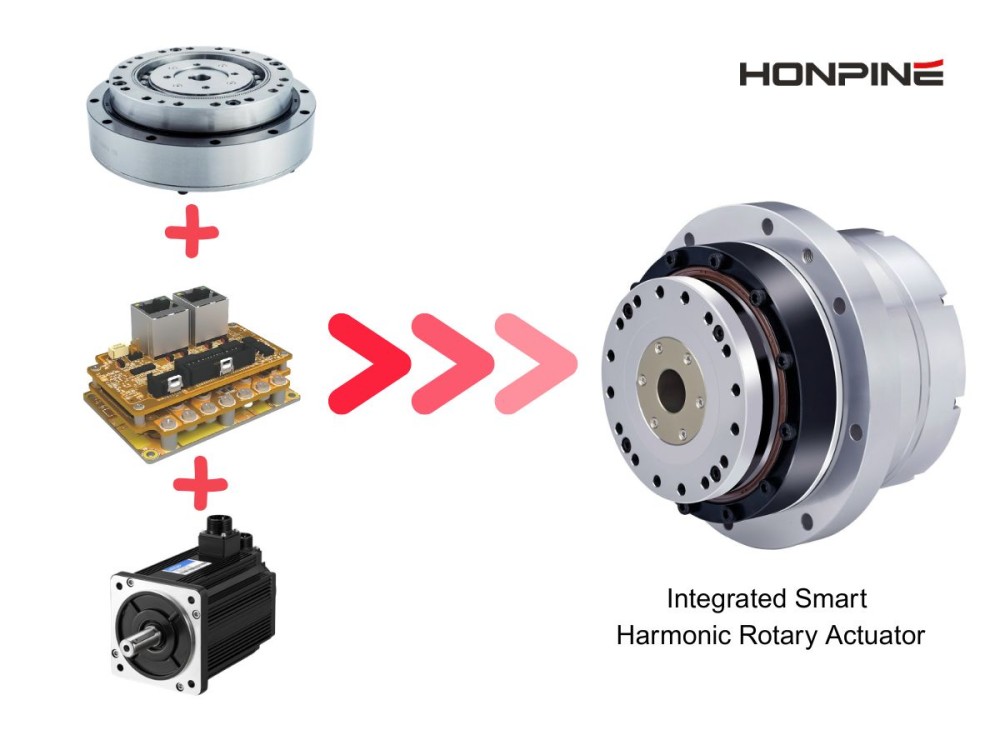

The HONPINE Harmonic Servo Actuator, with its fully integrated architecture, significantly shortens the development cycle for medical robotic systems.

Why Choose HONPINE Harmonic Servo Actuators?

Medical devices demand extreme precision, stability, safety, and compact integration—and our actuator is engineered precisely for these needs.

1. Micron-level positioning accuracy

High-resolution absolute encoders and zero-backlash harmonic transmission deliver smooth, sub-micron repeatability—critical for surgical robots, imaging platforms, and diagnostic mechanisms.

2. Large hollow bore design

Allows optical fibers, endoscope tubes, drive shafts, and cables to pass directly through the center—enabling cleaner layouts and compact, sterilizable mechanical structures.

3. Superior dynamic performance

Triple-loop vector control delivers low-vibration, overshoot-free motion with millisecond-level response—ideal for patient-critical movement control.

4. Medical-grade safety and redundancy

Dual closed-loop feedback, soft-start circuits, and complete fault diagnostics help prevent unexpected motion and ensure both operator and patient safety.

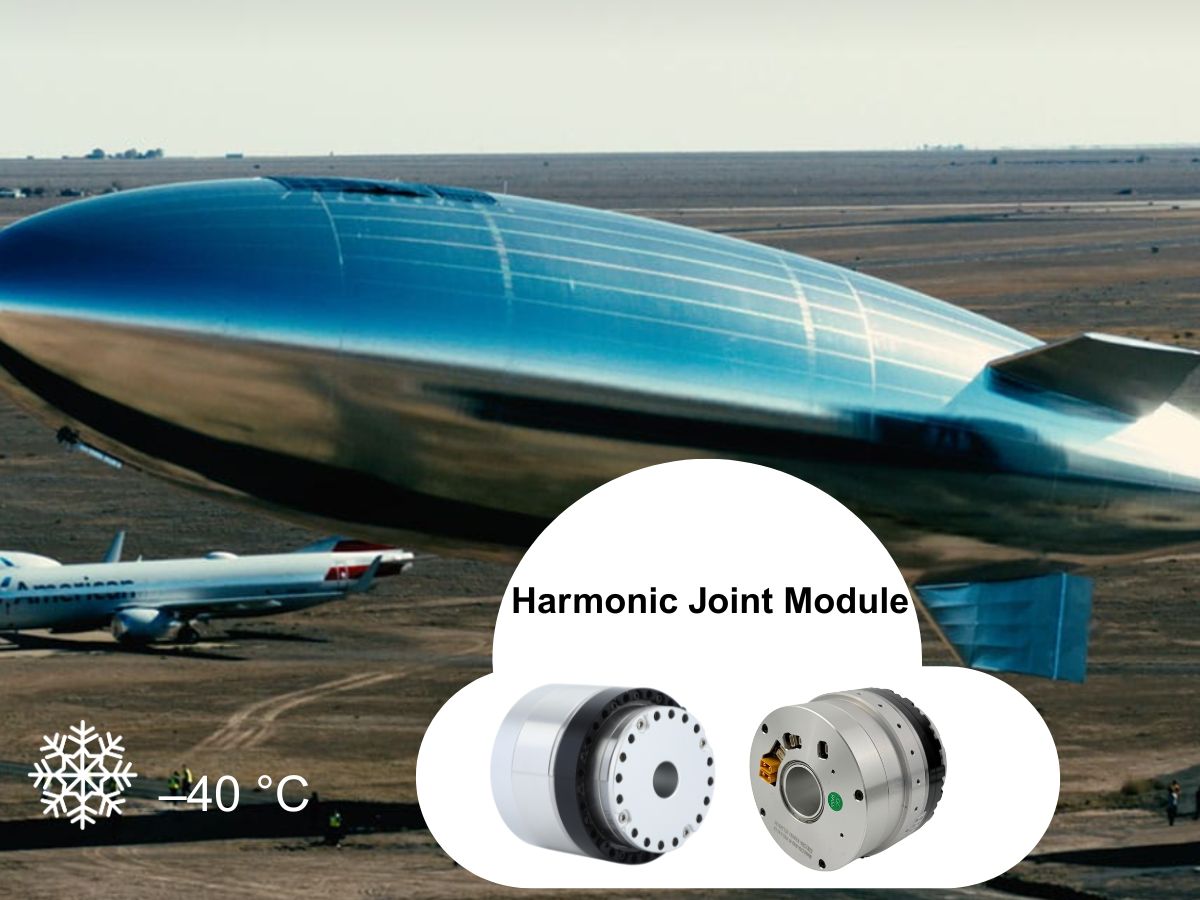

5. High environmental resilience

Wide temperature resistance, strong EMI shielding, and durable protective coatings ensure reliability even in demanding medical environments.

6. Compact, efficient, and quiet

Integrated harmonic drive, frameless torque motor, encoder, and IPM provide >90% efficiency with low noise—perfect for imaging tables, rehabilitation robots, and laboratory automation.

Medical robots, through precision control and intelligent functions, make medical operations safer, more efficient, more accurate, and lower risk.

Only by continuously innovating in technology, clinical adaptation, and global deployment can companies gain an advantage in the rapidly evolving field of healthcare robotics.

The original intention behind HONPINE’s harmonic servo actuator development is to collaborate with medical device innovators—and together shape the future of medical technology.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand