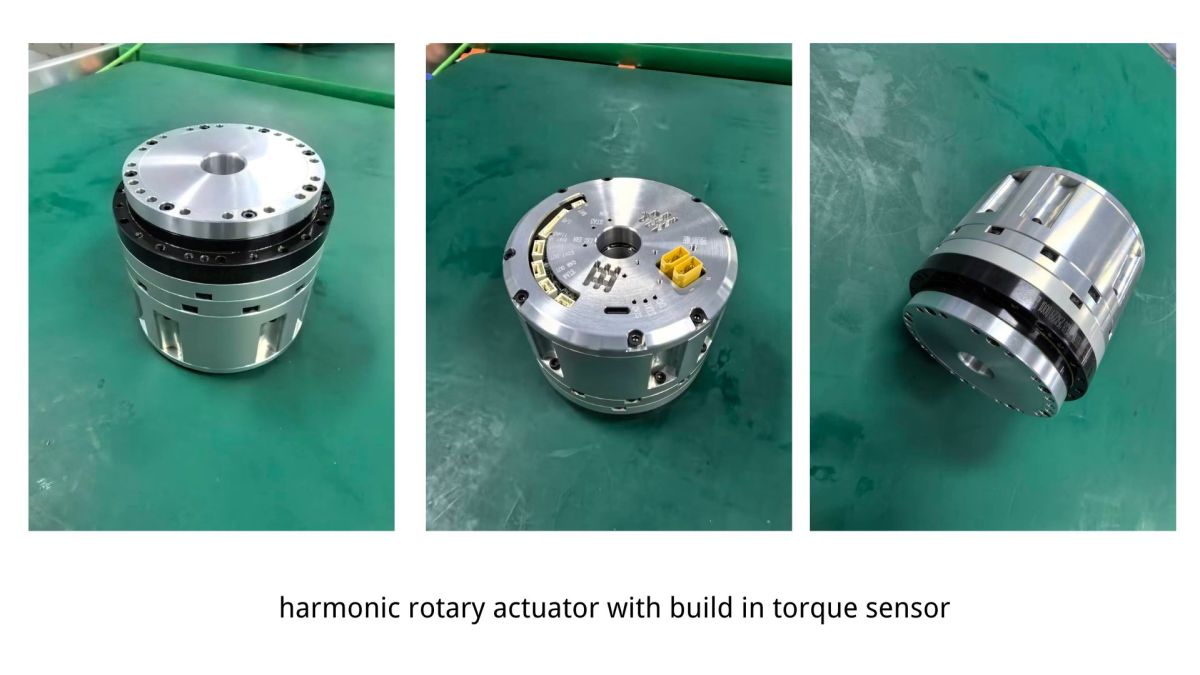

OMG Harmonic Drive Robot Rotary Actuator with Built-in Torque Sensor & STO

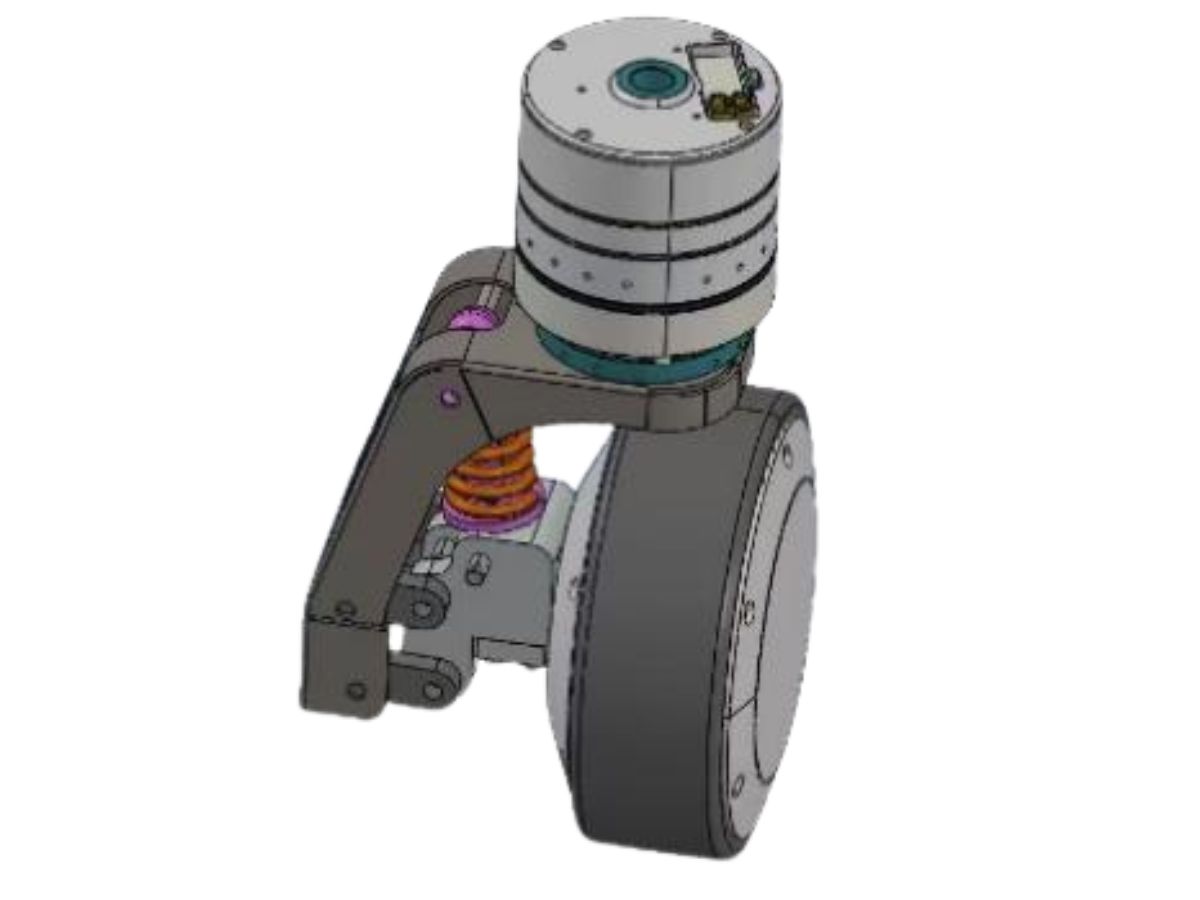

This is a game-changing robot rotary actuator!A conventional harmonic drive robot rotary actuator typically consists of a harmonic reducer, frameless torque motor, encoder, drive board, and housing.

This upgraded version goes far beyond the traditional design by reserving internal space for an integrated torque sensor, allowing customers to optionally equip a torque sensor without increasing the overall size or weight.

In addition, the actuator supports STO (Safe Torque Off), significantly enhancing operational safety during robot motion.

Why Integrate a Torque Sensor?

By integrating the torque sensor inside the robot rotary actuator, the joint’s overall weight and size are reduced, while still enabling direct output torque measurement without changing the external dimensions.

This design allows robots to achieve:

Higher dynamic response performance

Superior data acquisition quality

Greater load handling and grasping capability

Integrated torque sensing enables more precise force control and more intelligent motion behavior at the joint level.

Why Add STO (Safe Torque Off)?

The addition of STO is critically important for embodied intelligence systems.

The built-in torque sensor allows the robot to sense force, while STO ensures that the robot remains safe under all conditions. As embodied intelligence continues to evolve, robots are increasingly entering medical care, rehabilitation, household services, and other human-centered environments.

STO serves as the final safety barrier to protect humans during human-robot interaction.

In the era of Industry 5.0, where human-robot collaboration becomes more common and more human-centric, STO is an indispensable last line of safety defense for robotic production systems.

What Else Makes This Harmonic Drive Robot Rotary Actuator Outstanding?

Ultra-lightweight design

Robot actuators are the “muscles” of robots and account for a significant portion of total system weight. Lightweight actuators play a vital role in achieving overall robot lightweighting.

Extremely simple integration

The actuator supports plug-and-play installation, significantly reducing system integration complexity.

Advanced communication support

Supports both EtherCAT and CAN protocols.

Multi-dimensional connectivity

Even more impressively, the actuator supports multi-axis and multi-node network connections, enabling flexible system architectures.

Contact Us

Contact us to receive the latest information and technical documentation on HONPINE’s newest harmonic drive robot rotary actuators.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand