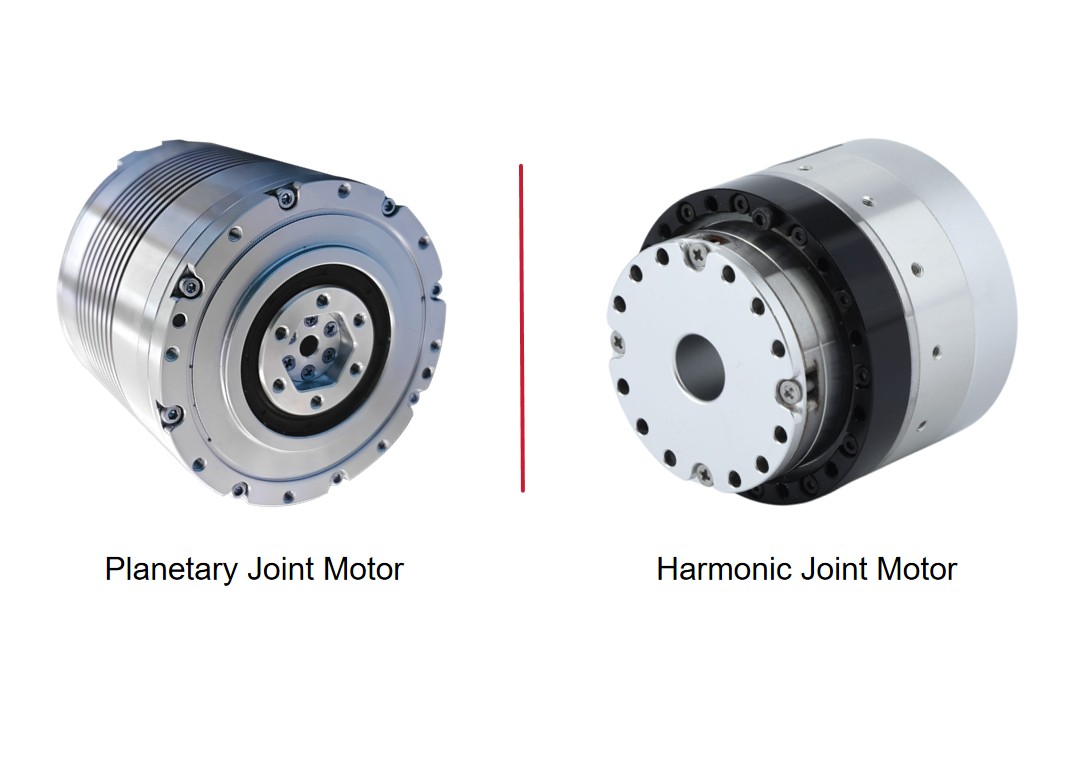

Harmonic Joint Motor VS Planetary Joint Motor

When collaborative robots precisely pick up chips, AGVs shuttle smoothly through shelves, or surgical robots perform millimeter-level operations, few people notice that the joint motor contains a "power heart" that determines its performance—the reducer. Among them, harmonic reducers and planetary reducers are two mainstream technical solutions, and their differences directly affect the precision, lifespan, and applicable scenarios of the joint motors.

How Harmonic Reducers Work in Joint Motors

Harmonic reducers stand out for their unique structural design. They mainly consist of a flexspline, circular spline, and wave generator. During operation, the wave generator causes elastic deformation of the flexspline, creating misaligned meshing with the circular spline to achieve speed reduction. This design brings many advantages. Firstly, it offers an ultra-high transmission ratio, easily reaching 50-300 in a single stage, meaning significant speed reduction can be achieved within a limited space. Moreover, it provides extremely high precision, allowing accurate control of the robot joint's rotation angle, with repeat positioning accuracy up to ±0.01mm. Additionally, harmonic reducers are compact and lightweight, making them particularly suitable for applications with strict space and weight requirements, such as the joints of collaborative robots. However, they also have weaknesses: the flexspline is subject to long-term alternating stress, making it prone to fatigue damage and a relatively shorter lifespan. Additionally, their heat dissipation conditions are poor, requiring extra attention during continuous high-load operation.

How Planetary Reducers Work in Joint Motors

The structure of planetary reducers is based on a planetary gear system, including a sun gear, planetary gears, planetary carrier, and ring gear. When the sun gear rotates, it drives the planetary gears to roll between the sun gear and the ring gear, thereby achieving speed reduction. The advantages of planetary reducers are equally outstanding. They offer high transmission efficiency, reaching 90%-95%, with minimal energy loss. Their compact structure, small size, and lightweight design make them easy to install. At the same time, they exhibit strong stability, are less prone to overshooting and impact forces during operation, and are less affected by temperature, allowing them to function normally within a wide temperature range. However, their precision is slightly inferior to that of harmonic reducers, which may make them less suitable for scenarios with extremely high precision requirements.

What Is the Biggest Difference Between Planetary Joint Motors and Harmonic Joint Motors?

From the perspective of the joint motor as a whole, modules using harmonic reducers offer high precision and compact size, enabling delicate movements. They excel in fields such as medical surgical robots and semiconductor precision positioning equipment. On the other hand, joint motors using planetary reducers, with their high efficiency and stability, play a crucial role in scenarios that demand high stability and efficiency, such as industrial automation production lines and logistics AGVs.

In summary, both harmonic reducers and planetary reducers have their own advantages, providing unique performance to joint motors in different application scenarios. When selecting a joint motor, it is essential to weigh the pros and cons of both based on actual needs to ensure optimal performance of the robot joint.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand