-

50kg-2T AMRs 50kg-2T AMRs Motion Control Module System Solutions

• Integrated Servo Driving Wheels that combine four core components – drive, motor, reducer, and wheel – into a single unit, reducing installation space by 35% and lowering the customer's Total Cost of Ownership (TCO).

• Rotary-Lifting Integrated Actuators utilize a fused reducer design that breaks through dimensional limits, reducing size by over 30% compared to traditional solutions while enhancing product stability.

• An Integrated Electrical System Architecture is achieved through embedded HMI installation and built-in driver cabling technology.

• Compatibility with HONPINE's EdgeAccess2 remote operation and maintenance software enables online OTA upgrades, reducing service costs.

![Human Robot Harmonic Joint Module with Torque Sensor and Integrated Cable Connector Human Robot Harmonic Joint Module with Torque Sensor and Integrated Cable Connector]() Human Robot Harmonic Joint Module with Torque Sensor and Integrated Cable ConnectorThe TCHL Harmonic Joint Module is a harmonic joint module that integrates a torque sensor directly into the harmonic drive reducer. The torque sensor enables precise measurement of the drive system’s operating status and required torque values, allowing accurate load detection of the actuator. This helps prevent overload and enables safer human–robot interaction.

Human Robot Harmonic Joint Module with Torque Sensor and Integrated Cable ConnectorThe TCHL Harmonic Joint Module is a harmonic joint module that integrates a torque sensor directly into the harmonic drive reducer. The torque sensor enables precise measurement of the drive system’s operating status and required torque values, allowing accurate load detection of the actuator. This helps prevent overload and enables safer human–robot interaction.

The module features fully integrated cables and connectors, allowing fast, precise component connections and enabling safe, responsive motion control through a highly integrated design.![Cobots Robot Arm T type Harmonic Rotary Joint Module Cobots Robot Arm T type Harmonic Rotary Joint Module]() Cobots Robot Arm T type Harmonic Rotary Joint ModuleThe T-type harmonic joint module is a highly integrated robotic joint unit that combines a harmonic reducer, torque motor, precision sensors, brake, and driver. It is called “T-type” because the output flange is perpendicular to the motor shaft, forming a T-shaped layout ideal for rotary robot joints.

Cobots Robot Arm T type Harmonic Rotary Joint ModuleThe T-type harmonic joint module is a highly integrated robotic joint unit that combines a harmonic reducer, torque motor, precision sensors, brake, and driver. It is called “T-type” because the output flange is perpendicular to the motor shaft, forming a T-shaped layout ideal for rotary robot joints.

Designed for collaborative robots, the module simplifies development by integrating key components into one compact, plug-and-play unit. This greatly shortens the development cycle, lowers costs, and makes building a robotic arm almost as easy as assembling LEGO blocks. Its high integration also improves maintenance efficiency and expands the applicability of robotic-arm technology.![Sealing Design Robot Joint Module for Underwater Operation Special Robot Sealing Design Robot Joint Module for Underwater Operation Special Robot]() Sealing Design Robot Joint Module for Underwater Operation Special RobotThe joint module achieves highly optimized volume and weight through fully integrated components including harmonic reducer, frameless torque motor, brake, encoder and driver, enabling precise motion control with greater torque output, higher accuracy, more compact size and lighter weight. We also provide customized solutions to meet specific requirements for personalized applications and special operating environments, with the most common customizations being waterproof versions (resistant to water splashes, sprays or underwater operation up to 1 meter depth) and low-temperature adaptations. This waterproof joint module is specifically designed for special robots operating underwater, developed as an enhanced version of our standard joint module with dedicated improvements to address waterproofing challenges in robotic joints.

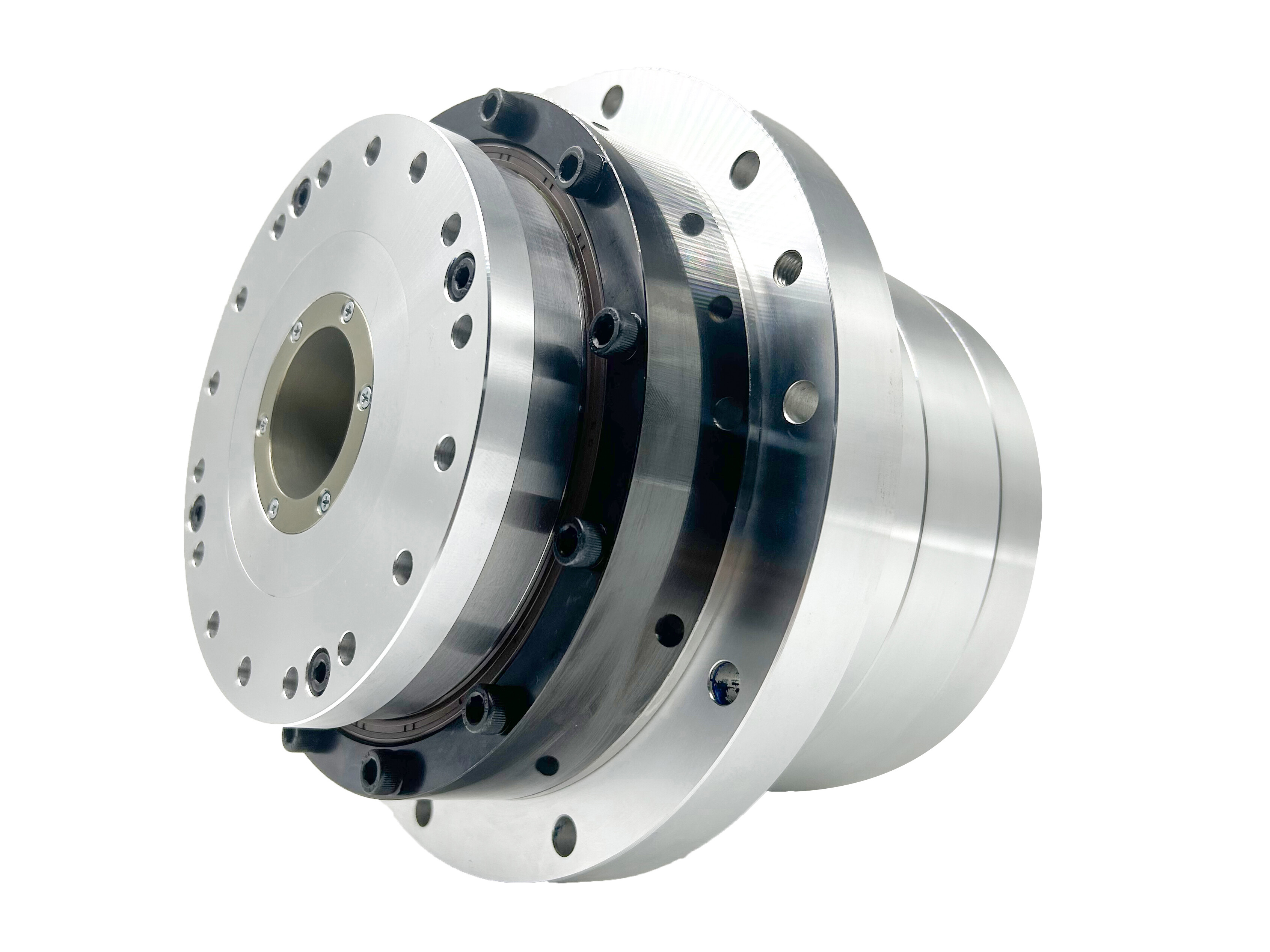

Sealing Design Robot Joint Module for Underwater Operation Special RobotThe joint module achieves highly optimized volume and weight through fully integrated components including harmonic reducer, frameless torque motor, brake, encoder and driver, enabling precise motion control with greater torque output, higher accuracy, more compact size and lighter weight. We also provide customized solutions to meet specific requirements for personalized applications and special operating environments, with the most common customizations being waterproof versions (resistant to water splashes, sprays or underwater operation up to 1 meter depth) and low-temperature adaptations. This waterproof joint module is specifically designed for special robots operating underwater, developed as an enhanced version of our standard joint module with dedicated improvements to address waterproofing challenges in robotic joints.![Large Hollow Bore Harmonic Drive Rotary Actuator Large Hollow Bore Harmonic Drive Rotary Actuator]() Large Hollow Bore Harmonic Drive Rotary ActuatorThe large hollow bore rotary actuator typically integrates an internal rotor frameless torque motor with components such as a harmonic drive reducer, absolute encoder, and customized large hollow bore harmonic drive unit to form a complete rotary actuator assembly. Its control unit (drive system) is usually externally mounted, enabling high-precision motion control for connected equipment. Compared to standard rotary actuators, this series features a larger hollow bore diameter, allowing passage of lead screws, cables, and other components. It is designed for applications requiring large through-bore space, high precision, and compact integration, such as machine tool rotary tables, precision medical devices, 5-axis laser cutting systems, and semiconductor equipment.

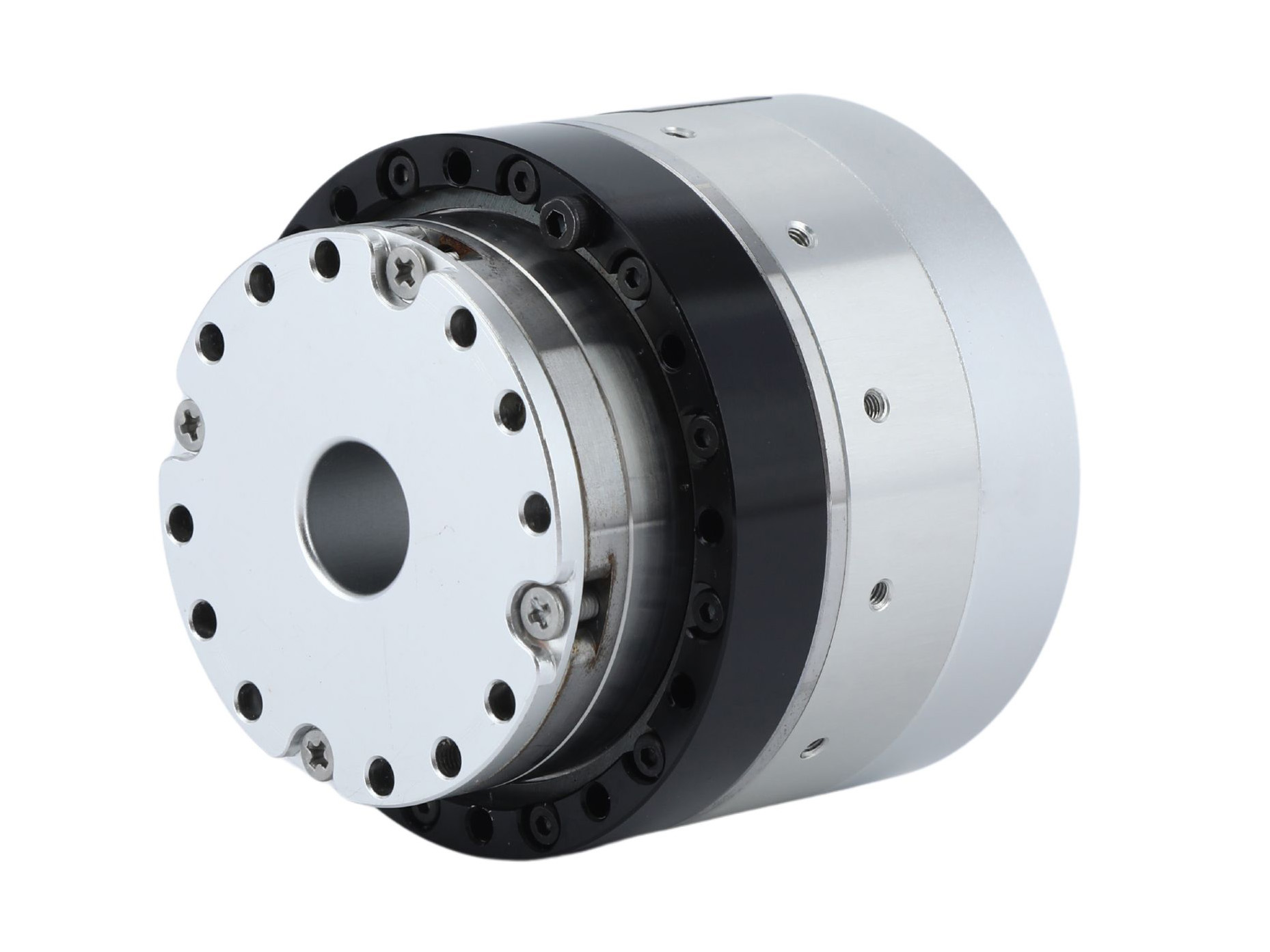

Large Hollow Bore Harmonic Drive Rotary ActuatorThe large hollow bore rotary actuator typically integrates an internal rotor frameless torque motor with components such as a harmonic drive reducer, absolute encoder, and customized large hollow bore harmonic drive unit to form a complete rotary actuator assembly. Its control unit (drive system) is usually externally mounted, enabling high-precision motion control for connected equipment. Compared to standard rotary actuators, this series features a larger hollow bore diameter, allowing passage of lead screws, cables, and other components. It is designed for applications requiring large through-bore space, high precision, and compact integration, such as machine tool rotary tables, precision medical devices, 5-axis laser cutting systems, and semiconductor equipment.![High Speed Impact Resistance Compact Lightweight Planetary Joint Module High Speed Impact Resistance Compact Lightweight Planetary Joint Module]() High Speed Impact Resistance Compact Lightweight Planetary Joint ModuleThe Standard Planetary Joint Module is a core component of robotic power systems. Through highly integrated design combining a planetary reducer, frameless torque motor, brake, encoder, and driver, it achieves significant optimization in volume and weight, enabling precise motion control of the joint. This results in greater torque, smaller size, and lighter weight. Compared to harmonic joint modules, the planetary joint module features a smaller reduction ratio, higher output speed, and greater torque density, making it more suitable for medium-to-low load applications. We also provide customization services tailored to clients’ specific requirements.

High Speed Impact Resistance Compact Lightweight Planetary Joint ModuleThe Standard Planetary Joint Module is a core component of robotic power systems. Through highly integrated design combining a planetary reducer, frameless torque motor, brake, encoder, and driver, it achieves significant optimization in volume and weight, enabling precise motion control of the joint. This results in greater torque, smaller size, and lighter weight. Compared to harmonic joint modules, the planetary joint module features a smaller reduction ratio, higher output speed, and greater torque density, making it more suitable for medium-to-low load applications. We also provide customization services tailored to clients’ specific requirements.

With core advantages such as high-speed performance, impact resistance, and compact lightweight design, the Standard Planetary Joint Module has become the preferred solution for high-load drives in humanoid robots, specialized robots, logistics AGVs, and industrial automation, driving advancements in robotic performance and broader application scenarios.![Highly Integrated Compact Harmonic Drive Robot Joint Motor Highly Integrated Compact Harmonic Drive Robot Joint Motor]() Highly Integrated Compact Harmonic Drive Robot Joint MotorThe Robot Joint Motor achieves highly precise motion control through integrated components including harmonic drive, frameless torque motor, brake, encoder, and drive unit, with optimized size and weight. It delivers greater torque, higher precision, more compact size and lighter weight. We also provide customization services according to customers' specific requirements.

Highly Integrated Compact Harmonic Drive Robot Joint MotorThe Robot Joint Motor achieves highly precise motion control through integrated components including harmonic drive, frameless torque motor, brake, encoder, and drive unit, with optimized size and weight. It delivers greater torque, higher precision, more compact size and lighter weight. We also provide customization services according to customers' specific requirements.

Robot Joint Motors typically support a wide voltage range of DC24V~DC48V. As a core component in robotics industry, the technological advancement of Robot Joint Motors will continue to promote the development of specialized robots and humanoid robots towards higher flexibility and broader application scenarios. Beyond robotics, Robot Joint Motors are also applied in semiconductor equipment, photovoltaic equipment, precision medical equipment, 3C equipment, optical equipment and other fields.![High Precision Flange Output Planetary Gear Reducer High Precision Flange Output Planetary Gear Reducer]() High Precision Flange Output Planetary Gear ReducerThe flange output planetary gear reducer is a precision transmission device that combines a planetary gear transmission system with a flange output structure. Its core components consist of a sun gear, planet gears, and an internal ring gear, achieving power transmission through single-stage or multi-stage gear meshing. The flange, serving as a critical connection component, features a circular design with integrated high-precision bearings, providing enhanced contact area and stable mounting support. Compatible with power sources such as servo motors and stepper motors, this reducer is widely employed in precision equipment across CNC machine tools, industrial robots, automated production lines, and aerospace applications.

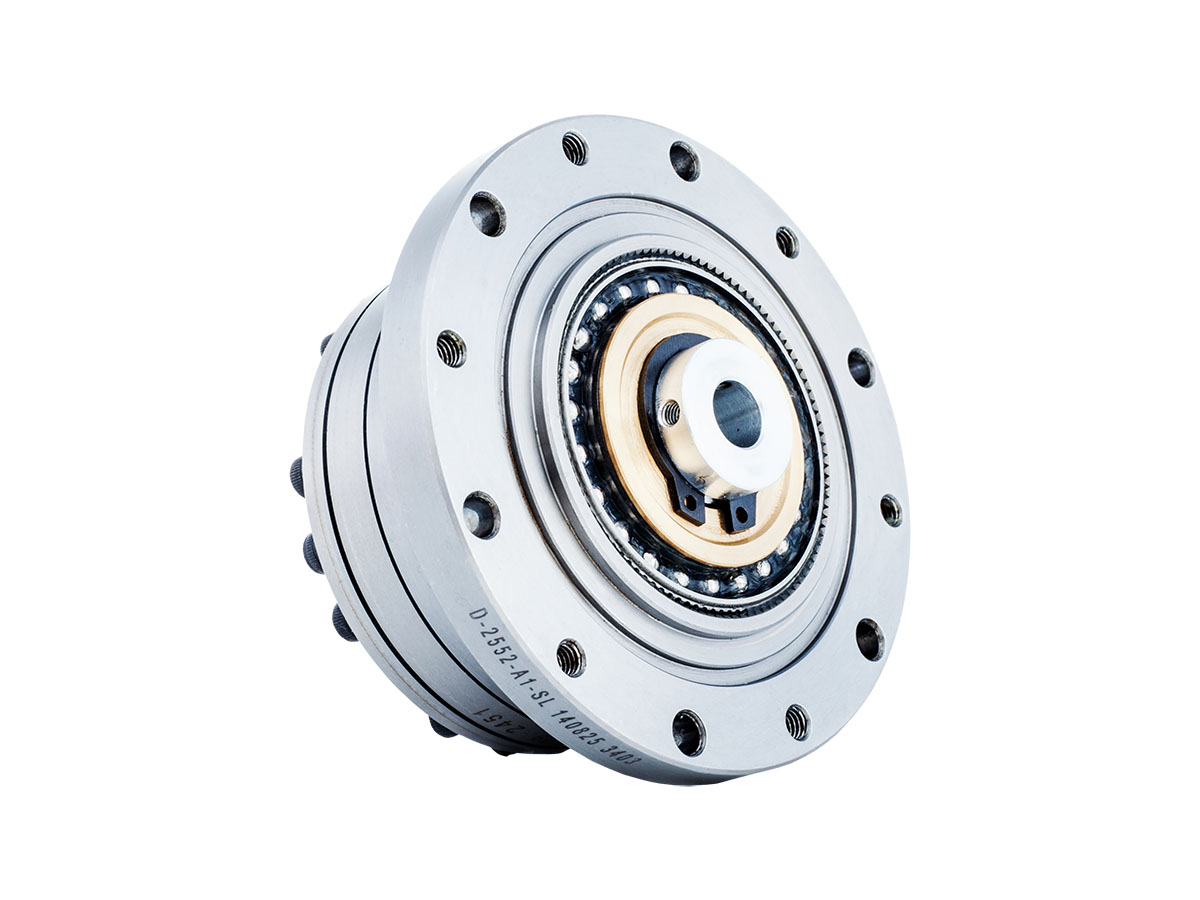

High Precision Flange Output Planetary Gear ReducerThe flange output planetary gear reducer is a precision transmission device that combines a planetary gear transmission system with a flange output structure. Its core components consist of a sun gear, planet gears, and an internal ring gear, achieving power transmission through single-stage or multi-stage gear meshing. The flange, serving as a critical connection component, features a circular design with integrated high-precision bearings, providing enhanced contact area and stable mounting support. Compatible with power sources such as servo motors and stepper motors, this reducer is widely employed in precision equipment across CNC machine tools, industrial robots, automated production lines, and aerospace applications.![Easy Installation Strain Wave Gear for Robot Arm and Sealed Rotary Tables Easy Installation Strain Wave Gear for Robot Arm and Sealed Rotary Tables]() Easy Installation Strain Wave Gear for Robot Arm and Sealed Rotary TablesThe FSG-II series strain wave gear utilizes a cross slider coupling mechanism for its wave generator. The cam shaft bore dimensions can be customized to accommodate specific motor models. The input shaft directly engages with the wave generator’s inner bore through a keyed connection. This configuration is typically implemented with the circular spline fixed at the base and the flexspline serving as the output end.

Easy Installation Strain Wave Gear for Robot Arm and Sealed Rotary TablesThe FSG-II series strain wave gear utilizes a cross slider coupling mechanism for its wave generator. The cam shaft bore dimensions can be customized to accommodate specific motor models. The input shaft directly engages with the wave generator’s inner bore through a keyed connection. This configuration is typically implemented with the circular spline fixed at the base and the flexspline serving as the output end.![Easy Installation Strain Wave Gear Support Custom Design to Match Motor Models Easy Installation Strain Wave Gear Support Custom Design to Match Motor Models]() Easy Installation Strain Wave Gear Support Custom Design to Match Motor ModelsThe FSG-I series Strain wave gear employs an integrated cam-type wave generator. The cam shaft bore dimensions can be customized to match customer-specific motor models. The input shaft directly interfaces with the wave generator's inner bore via a keyed connection. This system is typically configured with the circular spline fixed at the base and the flexspline functioning as the output end.

Easy Installation Strain Wave Gear Support Custom Design to Match Motor ModelsThe FSG-I series Strain wave gear employs an integrated cam-type wave generator. The cam shaft bore dimensions can be customized to match customer-specific motor models. The input shaft directly interfaces with the wave generator's inner bore via a keyed connection. This system is typically configured with the circular spline fixed at the base and the flexspline functioning as the output end.