Sealing Design Robot Joint Module for Underwater Operation Special Robot

● Introduction

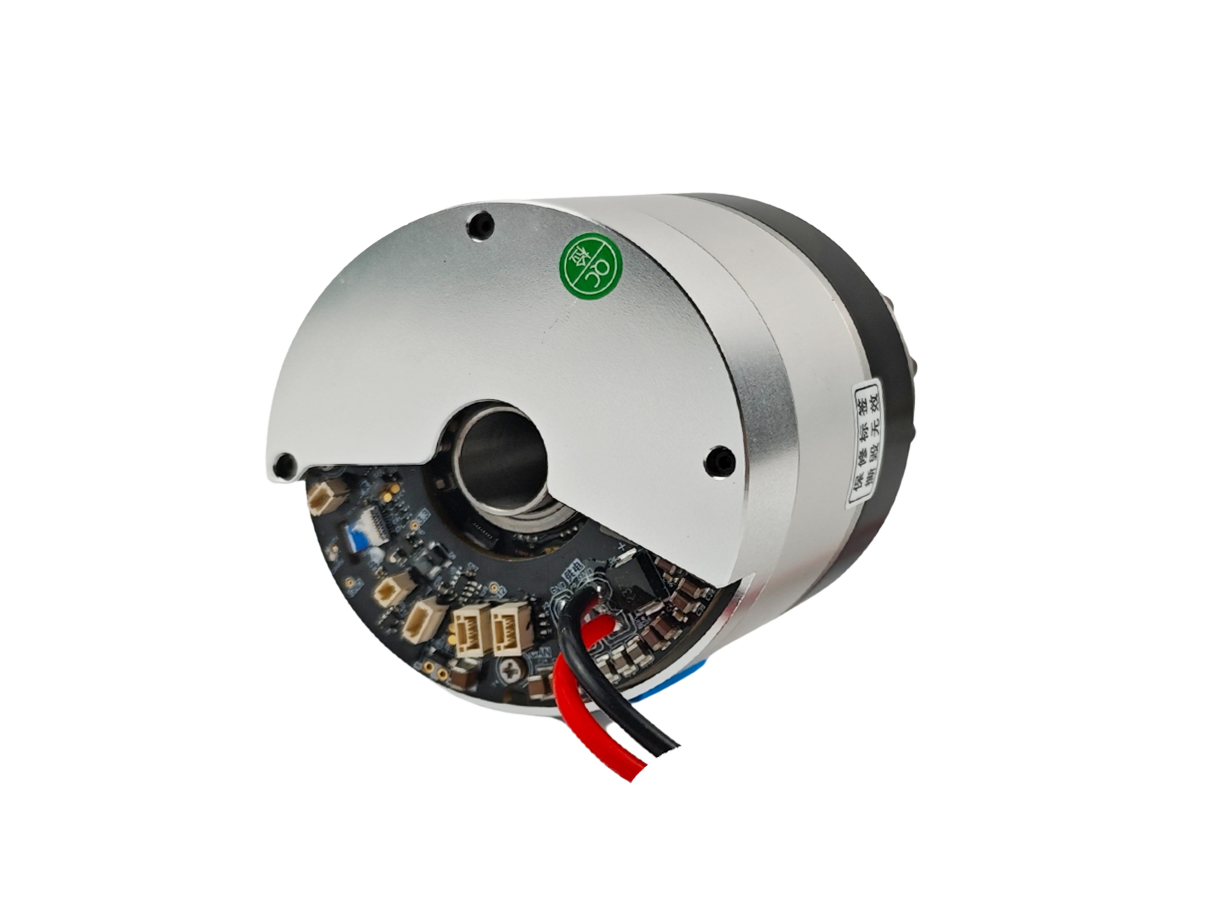

Core Components

For low-temperature customization, we use cryogenic lubricants and circuit board protections to support operation from -40°C to 65°C, withstanding humidity, high salinity, dust, and underwater conditions.

● Long-Term Reliability

Self-adaptive sealing requires zero maintenance for 6,000 hours; stainless steel housing significantly delays corrosion.

● Performance Stability

Sealing prevents liquid-induced short circuits or bearing wear, ensuring consistent torque output.

● Compact & Lightweight

Direct-drive integration reduces external transmission parts, lowering underwater motion resistance.

Features

● Sealing System

Junction Sealing: Multi-layer sealing with gaskets and adhesive, combined with protective components, blocks liquid intrusion at structural joints.

Dynamic Sealing: Dual-layer dynamic seals between the output component and housing effectively prevent liquid ingress.

Precision Contact Surfaces: Sealing surface roughness controlled to Ra0.1–Ra0.8, paired with oil films for micron-level sealing.

● Protective Housing

Stainless Steel Shell: Corrosion-resistant and mechanically robust, suitable for harsh environments like seawater.

IP67 Rating: Critical areas reinforced with protective components to block dust and liquids.

● Integrated Drive

Frameless motors directly coupled with harmonic reducers minimize exposed transmission parts, reducing overall size.

Specification

Sheet 1