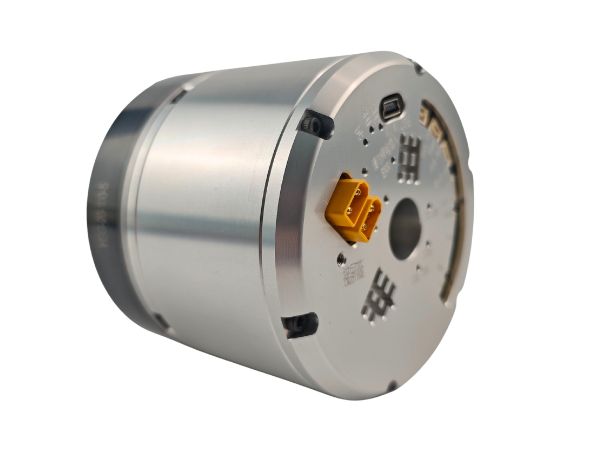

Why is it called a robot joint module instead of a robot joint motor? Because it's a module that integrates a harmonic reducer, encoder, servo motor, driver, and controller working together. In traditional robot manufacturing processes, companies often need to purchase these separate components individually, which is quite troublesome and often leads to compatibility issues, wasting both time and resources. A high-performance, integrated power module that combines all these components has become a market necessity.

Application of Harmonic Drive Robot Joint Module

In the field of humanoid robots, robot joint modules endow them with human-like flexibility and movement capabilities, completely transforming traditional robot design.

In robotic arm applications, the high precision and high torque characteristics of these robot joint modules make complex tasks effortless, improving production efficiency and quality.

In the aerospace industry, these robot joint modules not only enhance flight stability but also significantly reduce maintenance costs, ensuring safer flights.

In the medical device industry, integrated robot joint modules enable high-precision control for performing complex surgical procedures.

Features of Harmonic Drive Robot Joint Module

High torque density: Within a volume comparable to an adult joint, it outputs sufficient power to drive a limb.

Low torque fluctuation: This prevents "stuttering" during movement, which is particularly crucial for service robots and surgical robots. Currently, top-tier products have torque fluctuations controlled to within 0.5%.

Strong overload capacity: During sudden movements (such as sudden turns), the motor needs to withstand instantaneous loads 5-10 times its rated value; otherwise, "muscle weakness" may occur.

Extreme environment adaptability: From cold storage at -30℃ to high-temperature workshops, the motor needs to remain stable across a wide temperature range while also being resistant to dust and liquid ingress.

- OMG Ultra Compact Harmonic Drive Joint Module with Built-in Torque Sensor2026-01-27HONPINE TCHL series harmonic drive joint module is a game-changing product that achieves disruptive improvements in multiple aspects such as lightweight design, integration level, and connection convenience. This article will analyze its revolutionary enhancements with you.

- What is the Difference Between RV Reducer and Harmonic Reducer?2025-12-23This article provides an in-depth comparison between RV reducers and harmonic reducers, analyzing their differences from multiple perspectives, including working principles, performance characteristics, application fields, installation methods, and long-term maintenance.

- Harmonic Drive Gearbox – Complete Introduction and Analysis2025-10-13The Harmonic Drive Gearbox, also known as a Strain Wave Gearbox, is irreplaceable in applications requiring high precision, compact size, and low load.It is widely used in collaborative robots, servo systems, precision positioning and scanning equipment, aerospace, defense, and other high-precision systems.Thanks to its zero backlash, high reduction ratio, lightweight design, high positioning accuracy, and excellent repeatability, the harmonic drive has become an essential precision transmission solution in many advanced fields.

- Harmonic Joint Motor VS Planetary Joint Motor2025-09-04When collaborative robots precisely pick up chips, AGVs shuttle smoothly through shelves, or surgical robots perform millimeter-level operations, few people notice that the joint motor contains a "power heart" that determines its performance—the reducer. Among them, harmonic reducers and planetary reducers are two mainstream technical solutions, and their differences directly affect the precision, lifespan, and applicable scenarios of the joint motors.

- OMG Harmonic Drive Robot Rotary Actuator with Built-in Torque Sensor & STO2026-02-04This is a game-changing robot rotary actuator!A conventional harmonic drive robot rotary actuator typically consists of a harmonic reducer, frameless torque motor, encoder, drive board, and housing.

This upgraded version goes far beyond the traditional design by reserving internal space for an integrated torque sensor, allowing customers to optionally equip a torque sensor without increasing the overall size or weight.

In addition, the actuator supports STO (Safe Torque Off), significantly enhancing operational safety during robot motion.