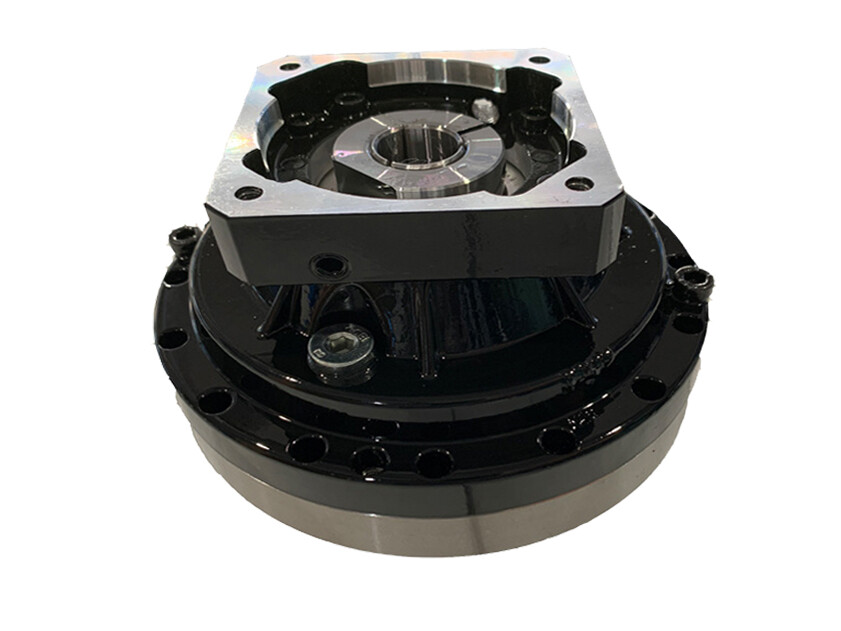

High Precision Two Stage Serve Motor Flange RV Reducer

● Introduction

Industrial Robotics Applications:

For robotic arms with end-effector payloads ≤20kg: Primarily deployed in base-to-high-load joints (typically J1-J4)

For robotic arms with end-effector payloads >20kg: All six joints utilize RV reducers

As the critical transmission component, RV reducers ensure exceptional positioning accuracy in robotic systems.

Application

● Solid Output Shaft Configuration

Pre-installed flange sealing with specialized RV lubrication for plug-and-play operation

● Two Stage Reduction System

Primary reduction: Involute planetary gear transmission for initial speed reduction

Secondary reduction: Cycloidal drive for enhanced torque stability

● Enhanced Structural Rigidity

a. Rigid disc support ensures optimal load distribution and minimal deformation

b. Multi-crank shaft assembly with precision bearings provides superior impact resistance

● Compact Enclosed Architecture

Integrated transmission mechanism within planetary carrier bearings minimizes axial dimensions

Features

● High-Precision Power Transmission

a. 50-7000 N·m torque capacity for heavy-duty applications (welding/material handling robots)

b. <1 arcmin backlash with exceptional repeat positioning accuracy (±16 arcsec)

● Extended Operational Lifecycle

a. ≥30-tooth meshing ensures uniform wear distribution (6,000-10,000 service hours)

b. Superior fatigue resistance compared to harmonic drives for continuous 24/7 operation

● Adaptive Performance Characteristics

a. 85%-95% transmission efficiency with minimized power loss

b. 31-203 reduction ratio range through customizable planetary gear configurations

● Dynamic Motion Performance

a. Low-vibration design ensures smooth operation without end-effector oscillation

b. Instantaneous acceleration response enables high-speed trajectory tracking

Specification

Sheet 1