What is harmonic drive motor?

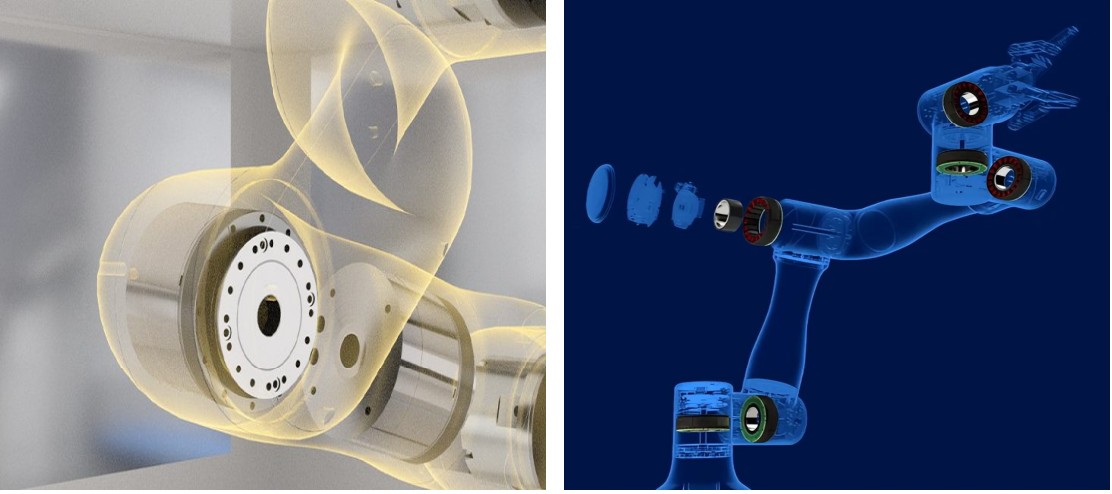

All harmonic drive motor adopt a highly integrated design of driver and motor, compactly integrating core components such as precision reducers, frameless torque motors, servo drivers, and encoders into a single module. This integrated drive and control system results in smaller joint size, simplified wiring, easier installation and debugging, and significantly reduces the overall failure rate of the machine. Downstream manufacturers can quickly build multi-degree-of-freedom robots using these standardized joint modules connected via a bus system.

Harmonic Drive Motors for Humanoid Robots

The multi-scenario applications of humanoid robots have also placed more systematic technical demands on harmonic joint mtorss, requiring a balance between lightweight design, high rigidity, and high power density. Furthermore, a high protection rating (such as IP65), vibration resistance, and electromagnetic compatibility are essential characteristics for adapting to complex industrial and outdoor environments. At the system integration level, the Tongchuan Precision HarmoCore series harmonic joints utilize an integrated electromechanical interface design, combining power transmission with real-time communication protocols such as EtherCAT and CAN FD in a single connector. The 8mm wire diameter supports hollow wiring, which not only improves the overall electromagnetic compatibility but also meets the stringent requirements for communication synchronization in multi-joint collaborative control. The IP65 protection rating ensures long-term operational stability in harsh environments such as those with dust and moisture.

How does HONPINE's harmonic drive motor overcome technological barriers?

Deep multidisciplinary coupling: It requires expertise in precision mechanical design, motor electromagnetics, servo control algorithms, thermal management, and materials science, and the ability to achieve cross-disciplinary optimization.

Extreme performance requirements: It pursues high power density (small size, high torque), high response bandwidth, low backlash, and high reliability. These indicators present "conflicts," requiring extreme trade-offs.

Core algorithms and software: Advanced algorithms for torque control, vibration suppression, and fault diagnosis are crucial.

- OMG Ultra Compact Harmonic Drive Joint Module with Built-in Torque Sensor2026-01-27HONPINE TCHL series harmonic drive joint module is a game-changing product that achieves disruptive improvements in multiple aspects such as lightweight design, integration level, and connection convenience. This article will analyze its revolutionary enhancements with you.

- What is the Difference Between RV Reducer and Harmonic Reducer?2025-12-23This article provides an in-depth comparison between RV reducers and harmonic reducers, analyzing their differences from multiple perspectives, including working principles, performance characteristics, application fields, installation methods, and long-term maintenance.

- Harmonic Drive Gearbox – Complete Introduction and Analysis2025-10-13The Harmonic Drive Gearbox, also known as a Strain Wave Gearbox, is irreplaceable in applications requiring high precision, compact size, and low load.It is widely used in collaborative robots, servo systems, precision positioning and scanning equipment, aerospace, defense, and other high-precision systems.Thanks to its zero backlash, high reduction ratio, lightweight design, high positioning accuracy, and excellent repeatability, the harmonic drive has become an essential precision transmission solution in many advanced fields.

- Harmonic Joint Motor VS Planetary Joint Motor2025-09-04When collaborative robots precisely pick up chips, AGVs shuttle smoothly through shelves, or surgical robots perform millimeter-level operations, few people notice that the joint motor contains a "power heart" that determines its performance—the reducer. Among them, harmonic reducers and planetary reducers are two mainstream technical solutions, and their differences directly affect the precision, lifespan, and applicable scenarios of the joint motors.

- Neugart Apex WITTENSTEIN Alpha Stober Planetary Reducer Gearboxes Can Be Replaced By HONPINE Based on Their Structural Advantages2026-02-04As a high-end Chinese brand of precision planetary reducer gearboxes, HONPINE planetary reducer gearbox is steadily gaining market recognition thanks to its outstanding structural design advantages and strong manufacturing coordination capabilities.

HONPINE planetary reducer gearbox can serve as a direct replacement for well-known international brands such as Neugart, Apex, WITTENSTEIN alpha, and Stober. Our goal is to deliver the same performance and reliability at a significantly more competitive cost, allowing customers to achieve equivalent application results with better value.

This article explains the key structural advantages of HONPINE planetary reducer gearboxes.