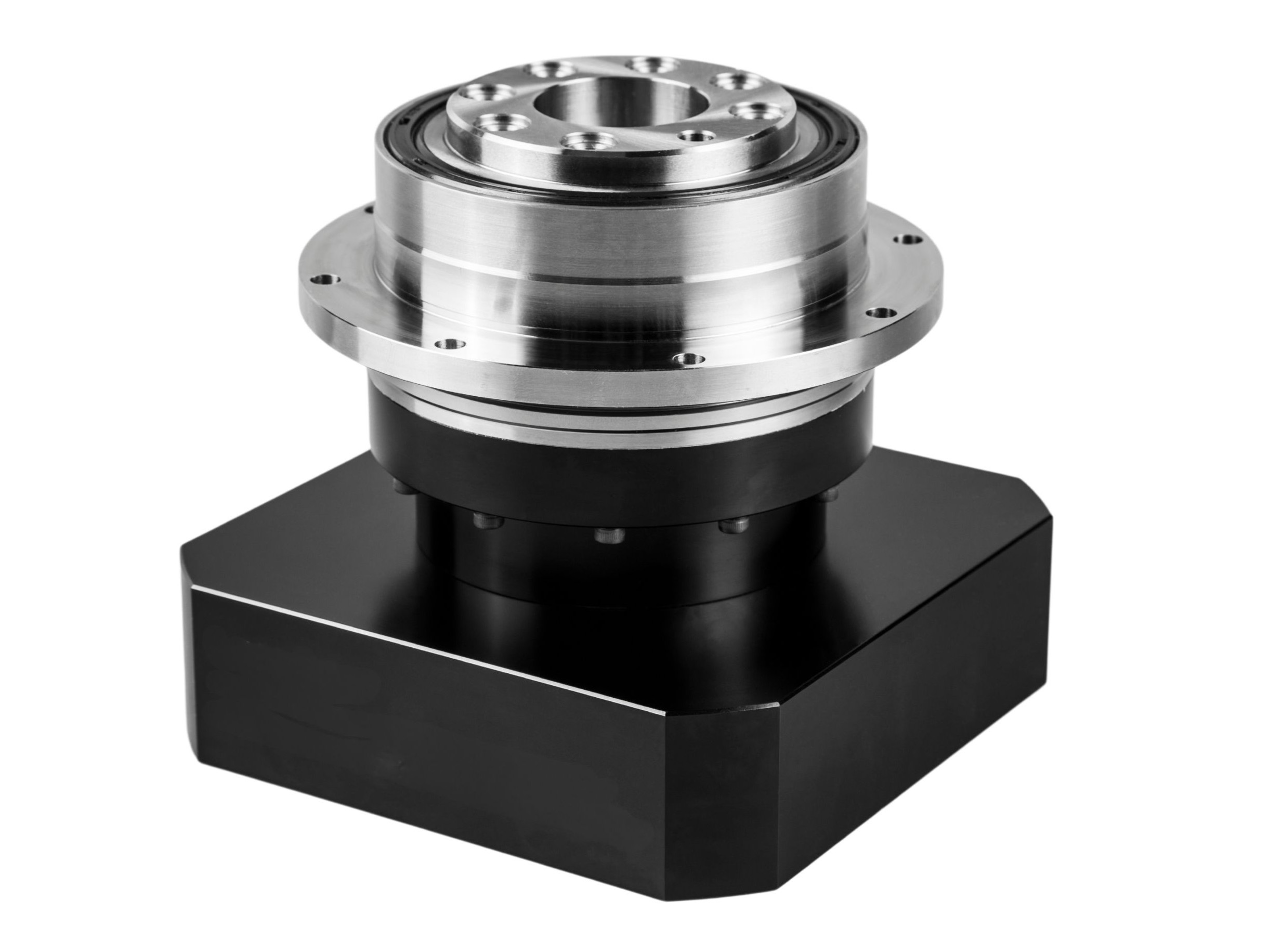

High Precision Flange Output Planetary Gear Reducer

● Introduction

Features

Equipped with high-precision bearings, the flange output design delivers an enlarged contact area, stable mounting support, enhanced positional accuracy, superior tensile stiffness, and exceptional torsional strength.

● Full Helical Gear Transmission for Higher Efficiency

All helical gear engagement ensures superior transmission efficiency: up to 97-98% for single-stage and maintained over 90% for multi-stage configurations.

● High Precision & Low Backlash

Precision grinding technology combined with a collet clamping mechanism minimizes backlash to ≤1 arcmin (1/60°), meeting stringent positioning accuracy requirements for servo systems.

● Monolithic Design for Enhanced Rigidity

Integrated planetary carrier, internal ring gear, and sun gear eliminate secondary riveting points, achieving unparalleled structural integrity.

● High Load Capacity

Multi-tooth meshing distributes loads efficiently. With carburized/quenched gears and needle roller bearings, the reducer delivers output torque up to thousands of N·m and outstanding impact resistance.

● Noise Reduction & Operational Stability

Patented noise-damping architecture and helical tooth flank rolling engagement reduce operational noise to ≤65 dB while ensuring vibration-free smoothness.

● Durability & Maintenance-Free Operation

Premium seals and permanent lubrication technology extend service life to over 20,000 hours, even in harsh environments with high temperatures or particulate contamination.

Specification

Sheet 1

Sheet 2

- planetary gear reducer

- planetary reduction gearbox

- planetgear speed reducer

- planetary speed reducer

- planetary reducer gearbox

- planetary gear reduction box

- planetary gear reduction system

- planetary gearbox reducer

- precision planetary reducer

- cnc planetary gear

- cnc planetary reducer

- cnc planetary gearbox