Why Harmonic Drive Actuators Are Ideal for Solar Photovoltaic Tracking Systems?

Solar photovoltaic tracking systems improve efficiency by adjusting the angle of PV panels. Their high transmission accuracy and smooth motion ensure that the panels continuously and efficiently receive sunlight, thereby significantly increasing the overall power generation efficiency of photovoltaic power plants.They can also be used in wind turbine blade pitch control systems. By precisely adjusting the blade angle, wind energy capture efficiency can be optimized, while ensuring turbine safety under strong wind conditions and enabling efficient power transmission.This article explains why harmonic drive actuators are well suited for solar photovoltaic tracking systems.

Requirements of PV Tracking Systems for Actuators

Solar photovoltaic tracking systems (single-axis or dual-axis) are essentially low-speed, high-precision rotary motion systems designed for long-term continuous operation.They require actuators with high positioning accuracy and repeatability, as angular errors directly affect the angle of solar incidence and thus energy yield.In addition, structural rigidity is critical. PV panels have a large wind-facing area, so the actuator must withstand significant dynamic torque loads.

From a long-term perspective, maintenance cost and energy consumption of the actuator must also be carefully considered.

Why HONPINE Harmonic Drive Actuators Are Suitable for Solar PV Tracking Systems?

1. Ultra-High Positioning Accuracy

HONPINE harmonic drive actuators rely on harmonic drive reducers as the core element for motion and power transmission.They feature extremely low backlash during operation. Some high-end products achieve:

Angular transmission error ≤ 5 arcseconds

Backlash controlled within 1 arcminute

Repeat positioning accuracy up to ±0.05 mm

With a high number of teeth engaged simultaneously and a large contact ratio, the motion is smooth, with minimal impact, vibration, and low operating noise.This allows PV panel angle adjustments to be more precise and tracking control to more closely follow the sun’s trajectory.

2. High Torque Density

Despite their compact size, HONPINE harmonic drive actuators can output high torque thanks to their compliant transmission design and high-quality materials.

Small modules can deliver torque from several to tens of newton-meters

Larger models can reach hundreds of newton-meters

Single-stage reduction ratios range from 50 to 161

They efficiently convert high-speed motor rotation into low-speed, high-torque output, reducing the overall weight of the solar tracking system, lowering support structure and foundation costs, and improving the stability of large-scale PV arrays.

3. Compact Structure

Compared with traditional gear reducers, HONPINE harmonic drive actuators can reduce volume by approximately two-thirds and weight by 50%, while integrating high reduction ratios within limited space.This effectively optimizes the structure of solar tracking systems by lowering the center of gravity, reducing inertia, and improving tracking response and control accuracy.

4. Low Maintenance Cost

HONPINE harmonic drive actuators feature low transmission energy loss, with efficiency ranging from 69% to 96%.Wear is evenly distributed across components, resulting in reliable operation and long service life. Apart from routine lubrication, no frequent or complex maintenance is required.Since photovoltaic tracking systems are often installed in deserts, Gobi regions, and mountainous areas, these characteristics significantly reduce maintenance costs and extend system lifespan.

5. Safe and Reliable Operation

Solar photovoltaic systems are frequently exposed to strong winds, gusts, and sandstorms.With their high reduction ratios, harmonic drive actuators effectively suppress back-driving. When combined with a holding brake, they can achieve power-off self-locking, ensuring safe positioning under extreme conditions.

With high precision, high torque density, smooth transmission, and exceptional reliability, harmonic drive actuators perfectly meet the core requirements of solar photovoltaic tracking systems—long-term operation, accuracy, stability, and low maintenance—making them an ideal actuation solution for high-end PV tracking applications.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

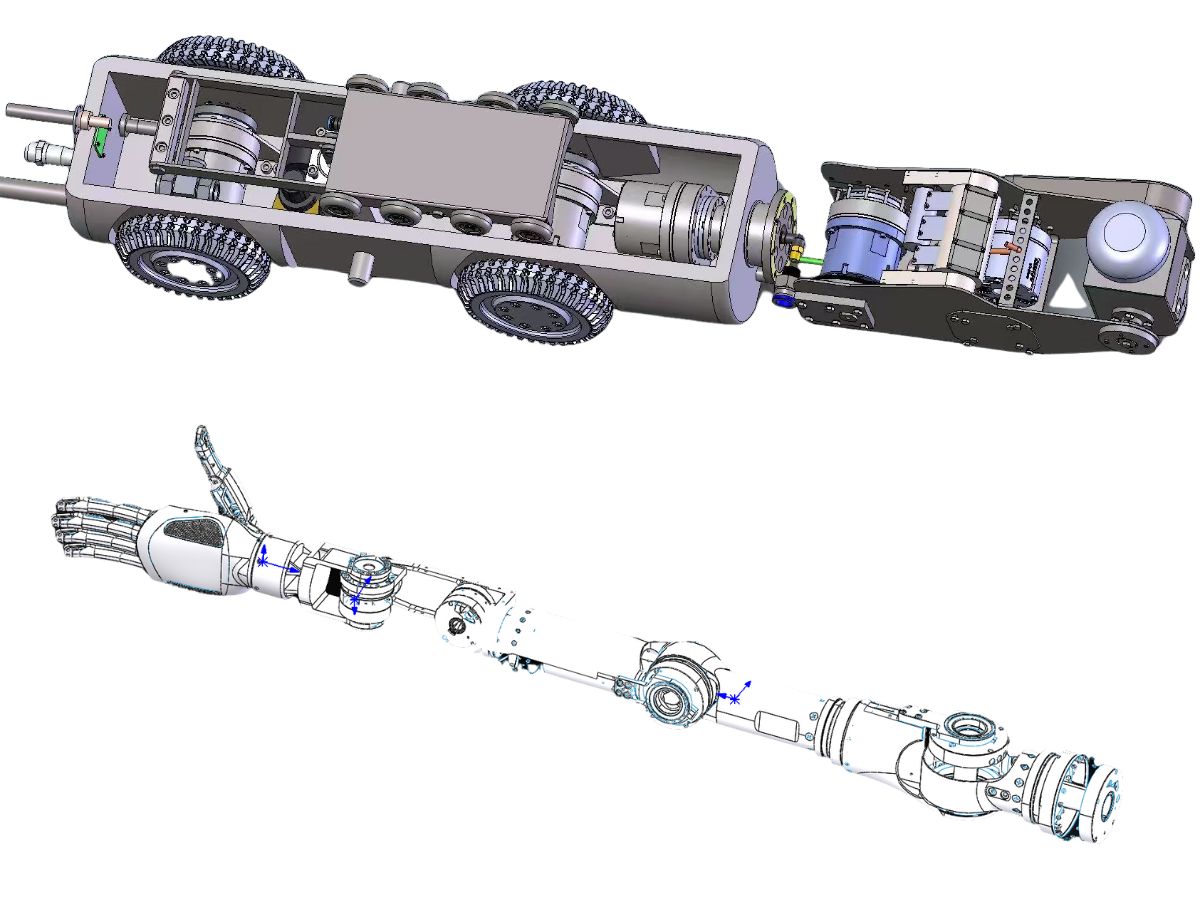

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand