How Precision RV Reducers are Revolutionizing Welding Positioner?

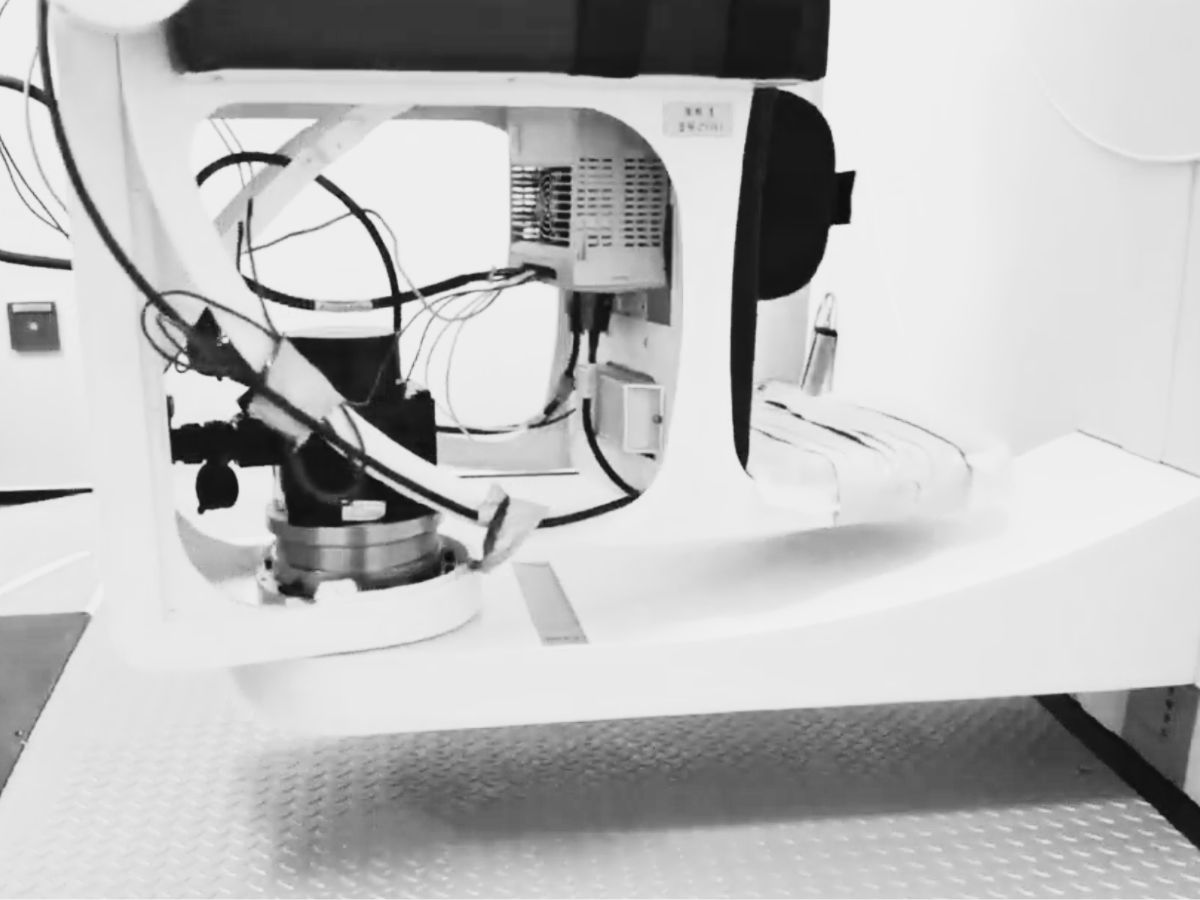

A positioner is an essential auxiliary device in welding operations. It rotates and positions workpieces to enable robots to achieve ideal processing positions and working speeds. Positioners can be customized according to different applications and requirements, including parameters such as different rotational axes, positioning accuracy, and movement speeds. RV reducers, with their high precision of 1 arc-minute (positioning accuracy up to ±0.01°), high rigidity (load capacity up to 10 tons), and low backlash (less than 1 arc-minute), have become the core component of welding positioners.

System Integration Solution of 120C RV Reducer for E-Bike Frame Welding Positioner Workstation

Servo Motor → RV Reducer 120C → C Positioner Turntable → D Frame Fixture

Adopts a dual-station design: while one station is welding, the other handles loading/unloading.

The RV120C directly drives the turntable spindle, eliminating transmission chain errors.

Custom flange plate adapts to frame fixtures (compatible with quick changeovers for multiple models).

Technical Advantages of RV Reducer Demonstrated

1. Accuracy Assurance

Welding path deviation reduced by 62%, decreasing subsequent correction man-hours.

Key hole alignment error on the frame is ≤0.15mm (industry standard is ≤0.5mm).

2. Efficiency Improvement

Repositioning time shortened to 3.2 seconds/90° (original worm gear mechanism required 8.5 seconds).

Workstation overall OEE (Overall Equipment Effectiveness) reaches 91%.

3. Maintenance Cost

Maintenance-free period >20,000 hours (compared to 5,000-hour maintenance for planetary reducers).

Unplanned downtime reduced by 85%, achieving annual maintenance cost savings of approximately ¥120,000.

Why Choose HONPINE RV Reducer?

Quality Improvement: First-pass weld qualification rate increased from 92.3% to 98.7%.

Production Capacity Breakthrough: Daily output per workstation reaches 180 frames (originally 120 frames).

Return on Investment: Additional equipment costs recovered within 11 months due to efficiency gains.

RV Reducer Solves Real-Time Posture Deviation Caused by Frame Welding Thermal Deformation

Achieves dynamic compensation through the RV reducer's millisecond-level response characteristics.

Integrated vision system performs real-time detection and triggers fine-tuning commands (adjustment range 0.03°–0.5°).

Data Verification: Post-compensation welding qualification rate increased by 7.2 percentage points.

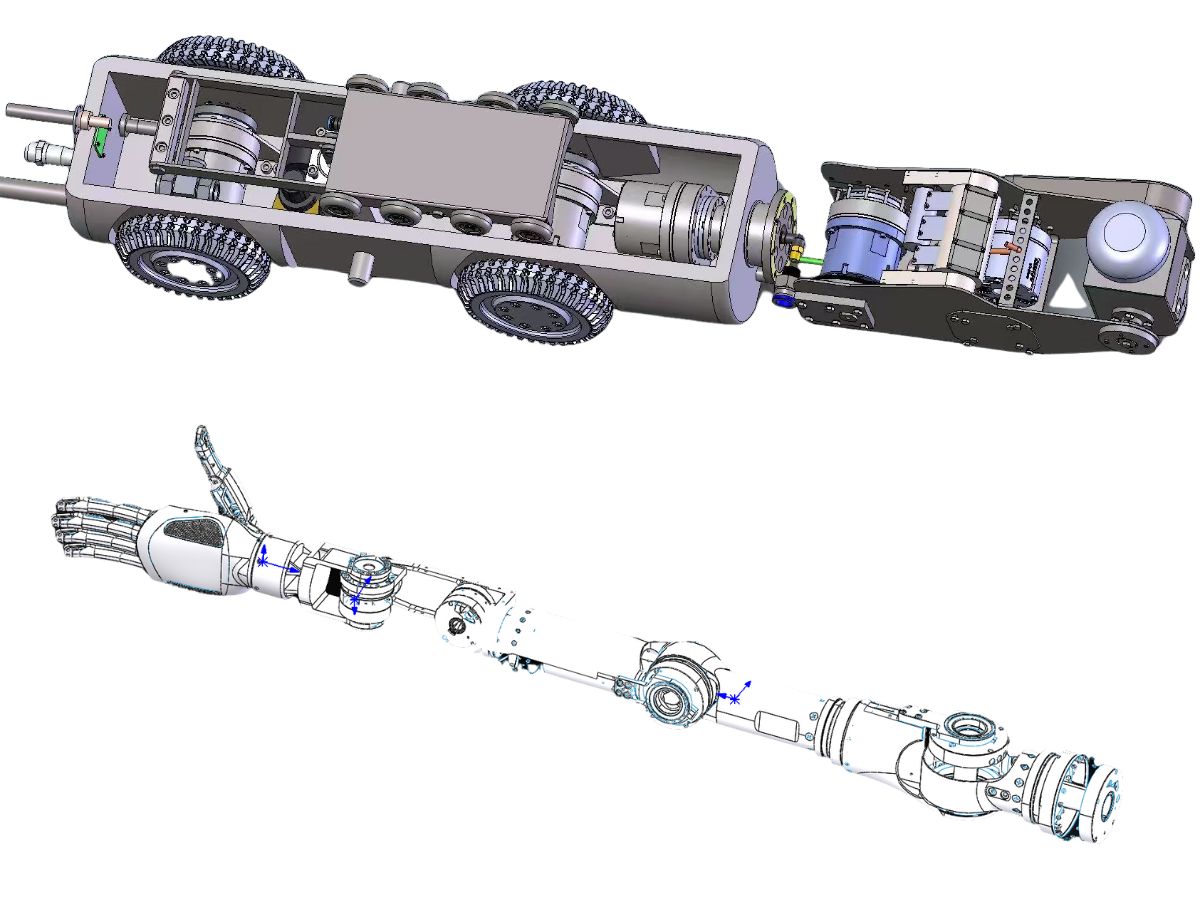

As a crucial device in the field of automated production, positioners play a significant role in industries such as machinery, automotive, aerospace, and shipbuilding.

The precision retention demonstrated by HONPINE RV reducers under heavy-load, high-frequency reversing operating conditions provides core motion assurance for high-cycle automated welding.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand