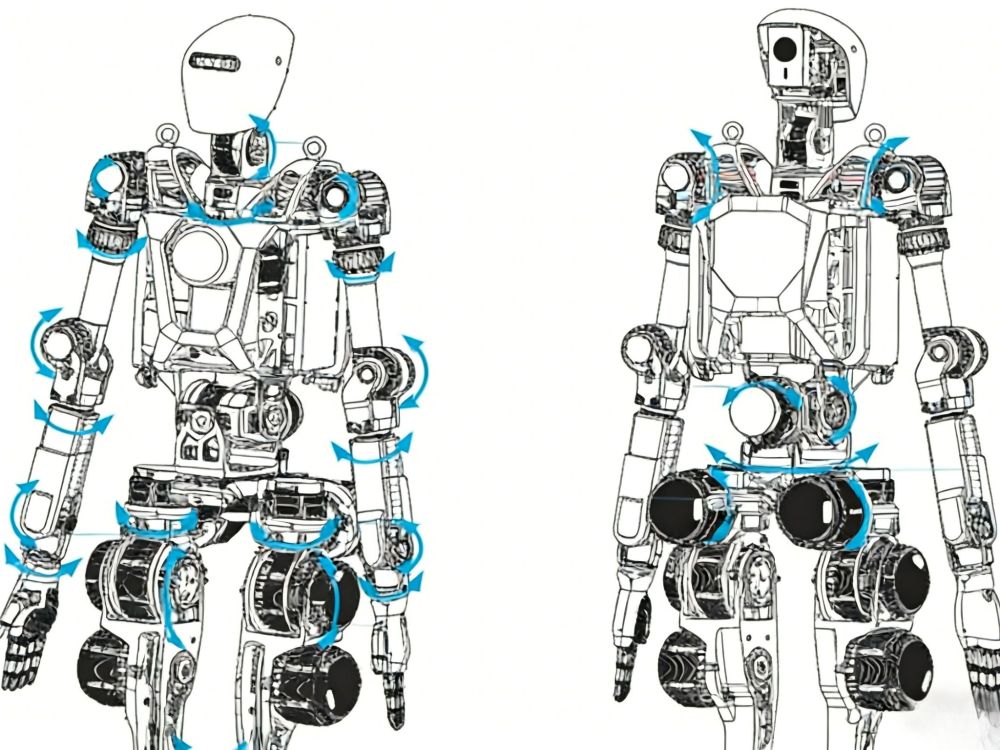

Complete Selection Guide for Robot Joint Motors — 9 Key Questions to Help You Choose the Right Model

As the “joints” of a robot, robot joint motors directly determine motion accuracy, load capacity, and service life. Many users make selection mistakes by overlooking critical parameters, leading to unnecessary costs and project delays. Don’t worry — this guide walks you through 9 essential questions + expert selection advice, helping you choose the right product in one go.

1. Working Environment

A. Indoor

B. Outdoor with shelter

C. Outdoor without shelter

D. Other (please describe)

Selection key points:

Indoor dry environments: basic protection (IP54)

Outdoor with shelter: enhanced dust- and water-proofing (IP65)

Outdoor without shelter: IP67 or higher

Special environments (ports, mines, corrosive areas): consider impact resistance and anti-corrosion design

The environment directly determines the required protection rating. Outdoor unsheltered applications must emphasize waterproofing and UV protection; harsh environments may require customized protection.

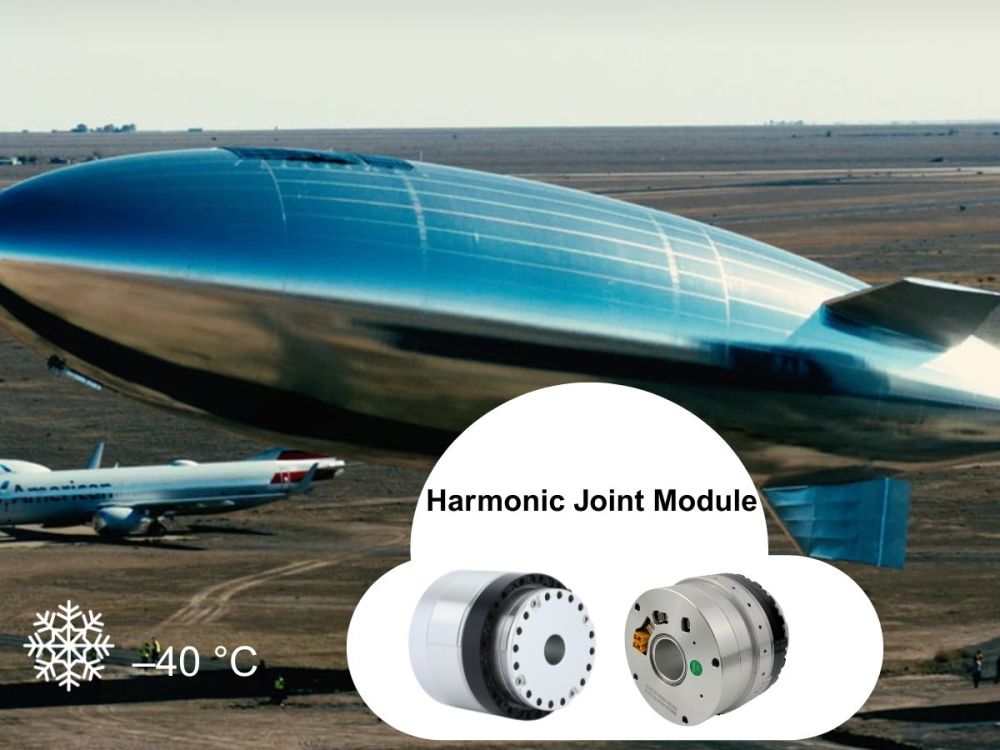

2. Ambient Temperature

A. Below –10℃

B. –10℃ to 40℃

C. Above 40℃

D. Other extreme conditions (please describe)

Selection key points:

Below –10℃: low-temperature-adapted motors (low-temp grease and seals)

Above 40℃: additional cooling structures

High-temperature applications (e.g., welding robot stations): reserve a safety margin of at least 10℃

Extreme temperatures affect motor performance — choose a robot joint motor with the appropriate temperature rating.

3. Ambient Humidity

A. Below 45%

B. 45%–65%

C. 65%–75%

D. Above 75% or underwater

High humidity requires enhanced moisture protection; underwater applications require professional waterproof structures.

4. Power Supply & Voltage

A. Lithium battery

B. AC power

C. Other (please describe)

Voltage options: 24V, 36V, 48V, or other values

Selection key points:

Mobile robots: lithium-battery-compatible models (check endurance)

Stationary equipment: AC-power versions

Voltage deviation must remain within ±10%

AGVs commonly use 24V/48V

Industrial robotic arms often use 36V

The joint motor must match the system’s power architecture to avoid instability.

5. Operating Mode

A. Speed mode (stable speed required)

B. Current/torque mode (for force-control precision)

C. Position mode (high-accuracy positioning)

D. Other (please describe)

Different modes correspond to different control requirements and determine the motor's control strategy.

6. Operating Speed & Duration

A. ≤10 rpm

B. 10–30 rpm

C. 30–60 rpm

D. Other (please provide values)

Single continuous operation duration: ______ hours.

Selection must consider duty cycle, thermal performance, and endurance.

7. Torque Requirement

A. 5–10 N·m

B. 10–20 N·m

C. 20–50 N·m

D. 50–100 N·m

E. 100–300 N·m

F. 300–500 N·m

G. Other (please specify)

Selection key points:

Use: Actual load torque × 1.2–1.5 safety factor

Vertical lifting applications: safety factor ≥1.5

Example: robotic arms handling 50 kg objects must calculate torque based on the lever arm, then add margin

Torque is the most critical parameter — always reserve safety margin to avoid overload.

8. Brake Requirement

A. With brake

B. Without brake

Brakes provide power-off self-locking. For vertical loads or position-holding applications, brakes are essential to prevent falling or drifting.

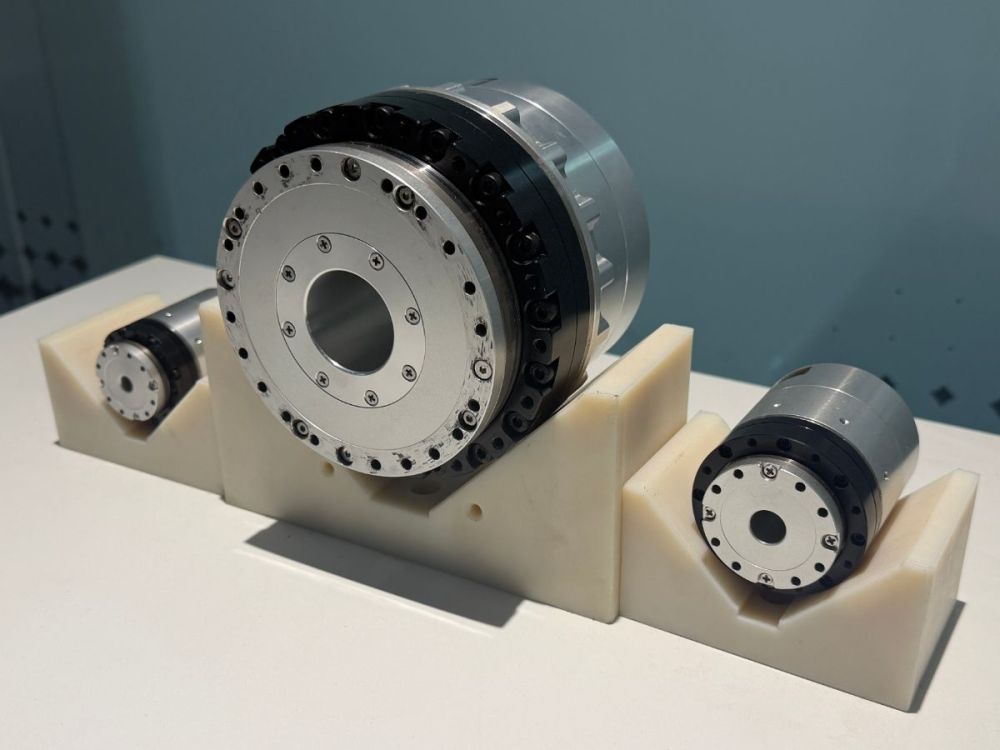

9. Hollow Shaft Diameter, Size & Weight Constraints

A. ≤10 mm

B. 10–20 mm

C. 20–30 mm

D. 30–40 mm

E. >40 mm

F. No hollow shaft

Please specify any restrictions on robot joint motor size and weight — lightweight equipment requires strict control of these parameters.

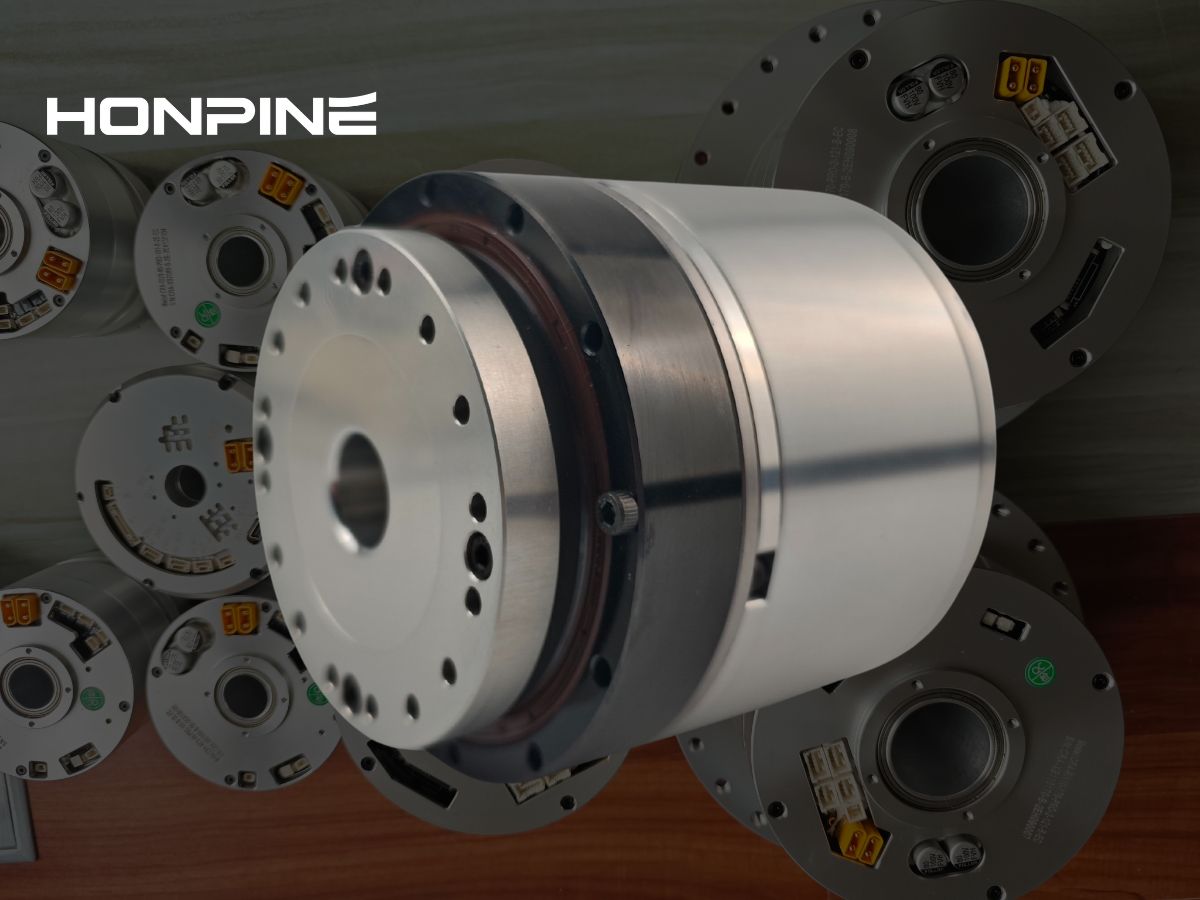

By answering the questions above, our engineers can provide free 1-on-1 customized selection support. You may also request the latest HONPINE robot joint motor catalog and 3D models.

If you have the device’s 3D model or application videos, our mechanical engineers can evaluate real working conditions and offer an optimized solution — helping you eliminate selection problems once and for all!

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand