How to Select Harmonic Gear Joint Modules for Humanoid Robots?

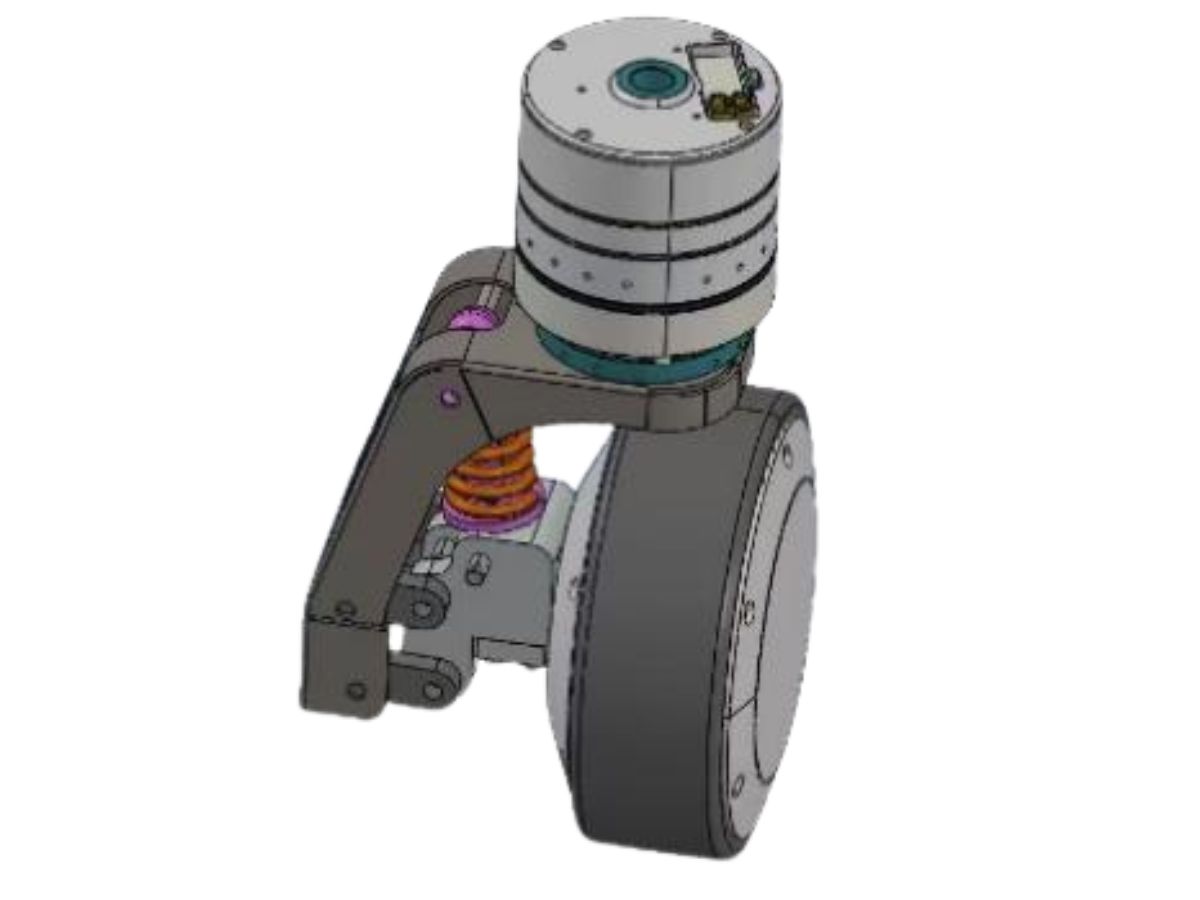

Harmonic gear joint modules serve as the "muscles and joints" of humanoid robots, accounting for 50%-60% of the total robot cost and determining key performance factors like motion precision and power output. Selecting harmonic drive joint modules directly influences a robot’s flexibility, load capacity, and suitability for various tasks. Using the HONPINE humanoid robot as an example, this guide explains how to match the right module to each joint.

What Are the Advantages of Harmonic Gear Joint Modules

HONPINE harmonic gear joint modules are "compact integration champions" and "versatile all-rounders." Within a diameter of just 4mm, they integrate a harmonic reducer, servo motor, high‑precision encoder, and drive electronics — plus these standout features:

Extreme Integration, Space‑Saving & Lightweight

Traditional joints require separate reducer, motor, and drive units, resulting in bulky wiring. Our modules weigh only 0.19 kg, allowing lighter, more compact joint designs — ideal for space‑constrained areas like the neck and wrist.

Small Size, High Torque

Take the HPJM‑RE30‑40‑PRO model: compact yet offering reduction ratios of 51:1 or 101:1, peak torque up to 3.3–4.8 N·m, and average load capacity of 1.8–2.4 N·m. It delivers "big performance in a small package," supporting arm lifting and stable leg movement under robot self‑weight.

Full‑Scenario Adaptability

Brake version: Auto‑locks on power loss — perfect for posture‑holding tasks (e.g., grasping and pausing).

Low‑temperature version: Operates reliably at ‑40°C — suitable for polar regions or cold‑chain logistics.

Waterproof version: IP67 rating withstands dust, moisture, and even deep‑sea conditions (e.g., underwater robots).

User‑Friendly Design, Easy Integration

Hollow‑shaft design: Various sizes allow internal cable routing, eliminating wire clutter.

Versatile communication: Single‑encoder models support CAN/CANopen/EtherCAT (choose one); dual‑encoder models support CAN/EtherCAT (except small‑size 30‑40/40‑52 versions). One module fits multiple control schemes without replacement.

Case Study: Harmonic Gear Joint Modules in a Humanoid Robot (Detailed Joint‑by‑Joint Selection Logic)

Different joints face vastly different demands — some need agility, others strength or precision. Here’s how HONPINE harmonic gear joint modules match each joint.

Two Key Parameters for Harmonic Gear Joint Module Selection

Positioning Accuracy

- Single‑encoder: ±0.05° absolute, ±0.005° repeatable — suitable for most applications.

- Dual‑encoder: Better than ±0.03° absolute, ±0.01° repeatable — for high‑precision tasks (note: 30‑40/40‑52 sizes do not support dual‑encoder).

Environmental Suitability

- Standard: IP50, ‑10°C to +50°C (derating may apply at high temperatures).

- Custom: ‑40°C low‑temperature or IP67 waterproof versions available for specialized environments (deep‑sea, extreme cold).

Module Selection Process — Simple & Reliable

Consultation: Share your robot requirements (load, operating scenario, precision).

Technical Discussion: Our engineers recommend the optimal model.

Order & Delivery: Confirm the model and receive direct factory shipment.

After‑Sales Support: Ongoing debugging and maintenance backed by factory‑level technical service.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand