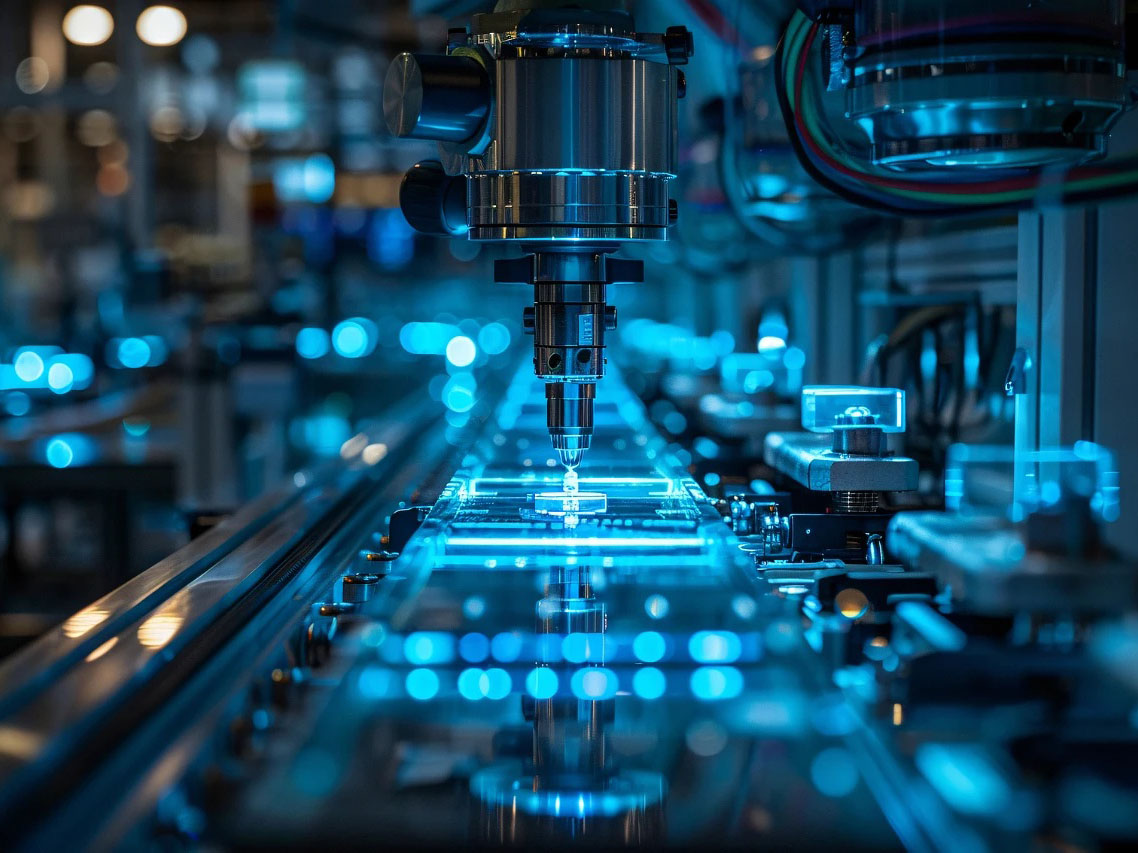

Harmonic Rotary Actuator Helps Implement the World’s First Track-Changing Aerial Mobile Smart EV DC Charging Station

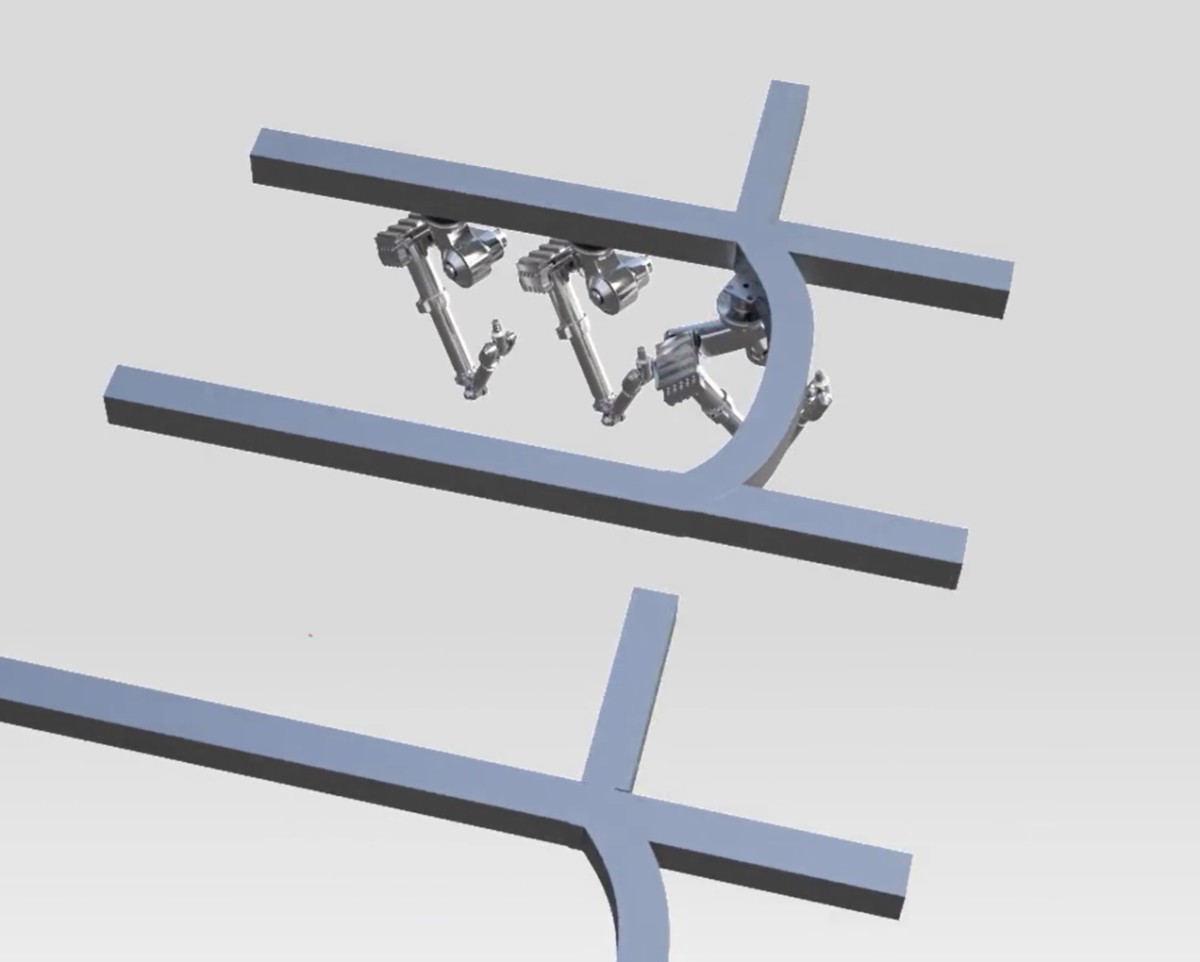

China’s first track-changing aerial mobile smart EV DC charging station has begun trial operations in over 10 cities. This project utilizes three major technologies: aerial track free lane switching, AI robotic automatic charging, and suspended installation design. The high precision, high torque, and lightweight characteristics of the harmonic rotary actuator have been crucial to the successful implementation of this project.

Why Could the Harmonic Rotary Actuator Make Such a Significant Contribution?

1. Harmonic Rotary Actuator Has a Built-in Harmonic Reducer

The zero-backlash and high-precision features of the harmonic rotary actuator enable it to perform minute angular adjustments. This ensures perfect alignment between the charging plugs and the vehicle's charging port in three-dimensional space—a prerequisite for fully automated charging plug targeting. Accurate and error-free insertion and extraction are essential to guarantee charging safety and extend the equipment's service life.

2. Harmonic Rotary Actuator Employs Lightweight Design

The aerial track system imposes strict requirements on the weight and volume of each moving unit. An overly heavy robotic arm would increase load and power consumption. As a key component of the robotic arm, the harmonic rotary actuator plays an important role in helping structural engineers design compact and lightweight robotic arms.

3. Harmonic Rotary Actuator Uses an Integrated Design

The harmonic rotary actuator is an integrated unit that combines a harmonic reducer, motor, and encoder. It converts the motor’s high-speed, low-torque output into low-speed, high-torque motion. This allows the robotic arm to perform more flexible and stable grasping, completing the charging plug insertion and extraction actions. The integrated design also reduces R&D time, enabling faster project deployment.

Why Choose HONPINE Harmonic Rotary Actuator?

HONPINE harmonic rotary actuators are shipped directly from the HONPINE factory, with over 80% of components produced in-house. This ensures comprehensive pre-sales and after-sales support. Our team includes professional structural engineers who provide expert guidance in product selection.

For more information about HONPINE harmonic rotary actuators, please contact us.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand