Harmonic Reducer Enables Industrial Humanoid Robot Walker S2 to Achieve Autonomous Battery Replacement for 24/7 Operation

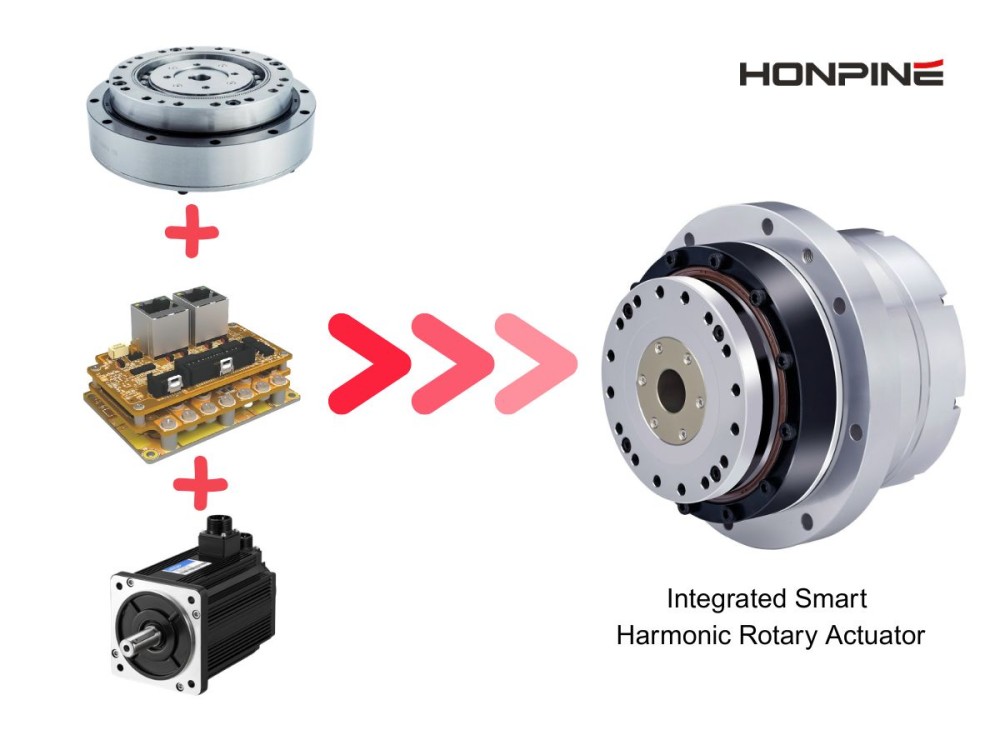

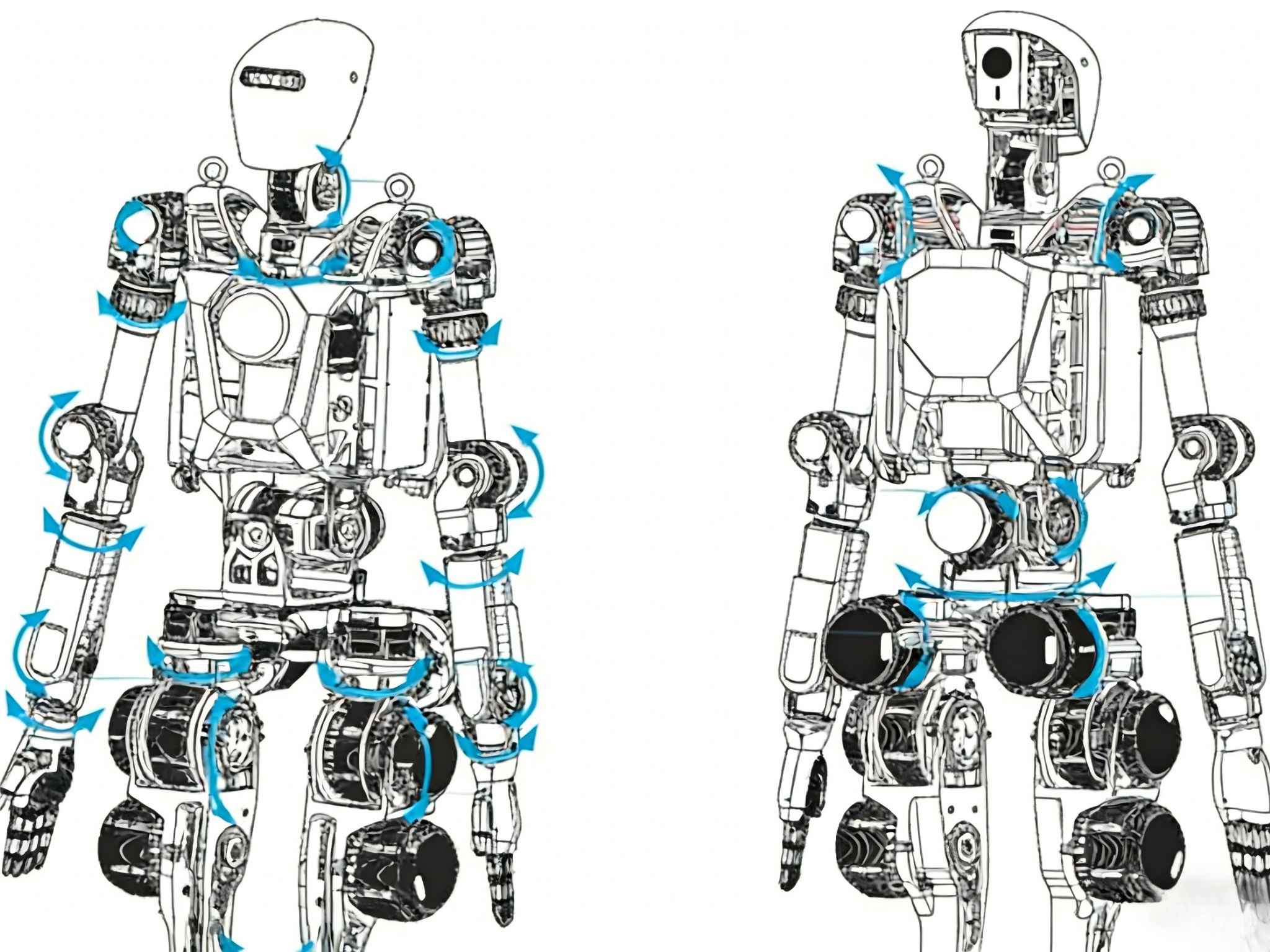

Without requiring manual intervention or shutdown, the humanoid robot can autonomously replace its battery in just 3 minutes. UBTECH Robotics, headquartered in Beijing Economic-Technological Development Area, recently announced exciting news: its new-generation industrial humanoid robot Walker S2 incorporates the world's first hot-swap autonomous battery replacement system for humanoid robots. This breakthrough technology endows Walker S2 with 24/7 continuous operation capability, establishing the foundation for smart manufacturing to achieve "non-stop next-generation productivity." The harmonic reducer's high reduction ratio, zero backlash, exceptional precision, high torque density, and lightweight design make it the optimal choice for joints in comparable industrial robots.

The humanoid robot's hot-swap autonomous battery replacement system features three key innovations:

Proprietary dual-battery power balance technology

Standardized battery compartment quick-change technology

Dual-arm collaborative precision battery replacement technology

The proprietary dual-battery power balance system utilizes real-time power monitoring and dynamic power balancing to enable simultaneous charging/discharging of both batteries. This facilitates seamless battery replacement, supports hot-swapping of powered batteries, and prevents inrush current and arcing - ensuring safe, stable, and continuous operation of the humanoid robots.

For standardized battery compartment quick replacement, UBTECH has developed modular battery units and zero-clearance compartment structures. This design allows batteries to function both as quickly replaceable energy components and integrated structural elements of the robot's body. The system employs a self-aligning locking mechanism that permits flexible switching between dual-battery endurance mode and single-battery operation.

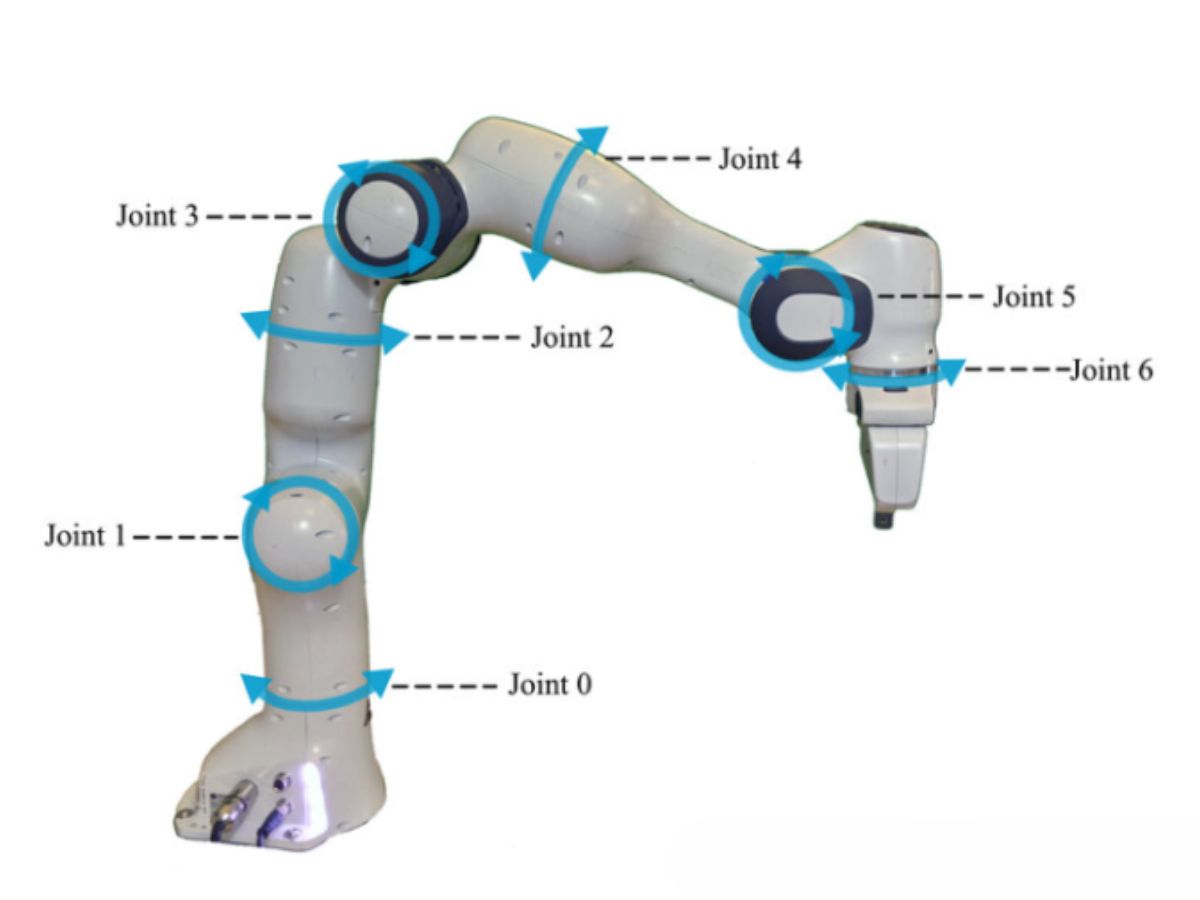

Humanoid robots demand precise joint angle control (for tasks like fine manipulation or walking balance). While traditional gear systems introduce positional errors due to backlash, harmonic reducers provide zero-backlash operation that guarantees accurate motion command transmission. The robot joints (including hips, knees, and shoulders) require substantial torque output that high-speed motors cannot deliver directly. Traditional gearboxes would be too bulky, whereas harmonic reducers achieve high reduction ratios (typically 50:1 to 160:1) within an extremely compact footprint while maintaining structural efficiency.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand