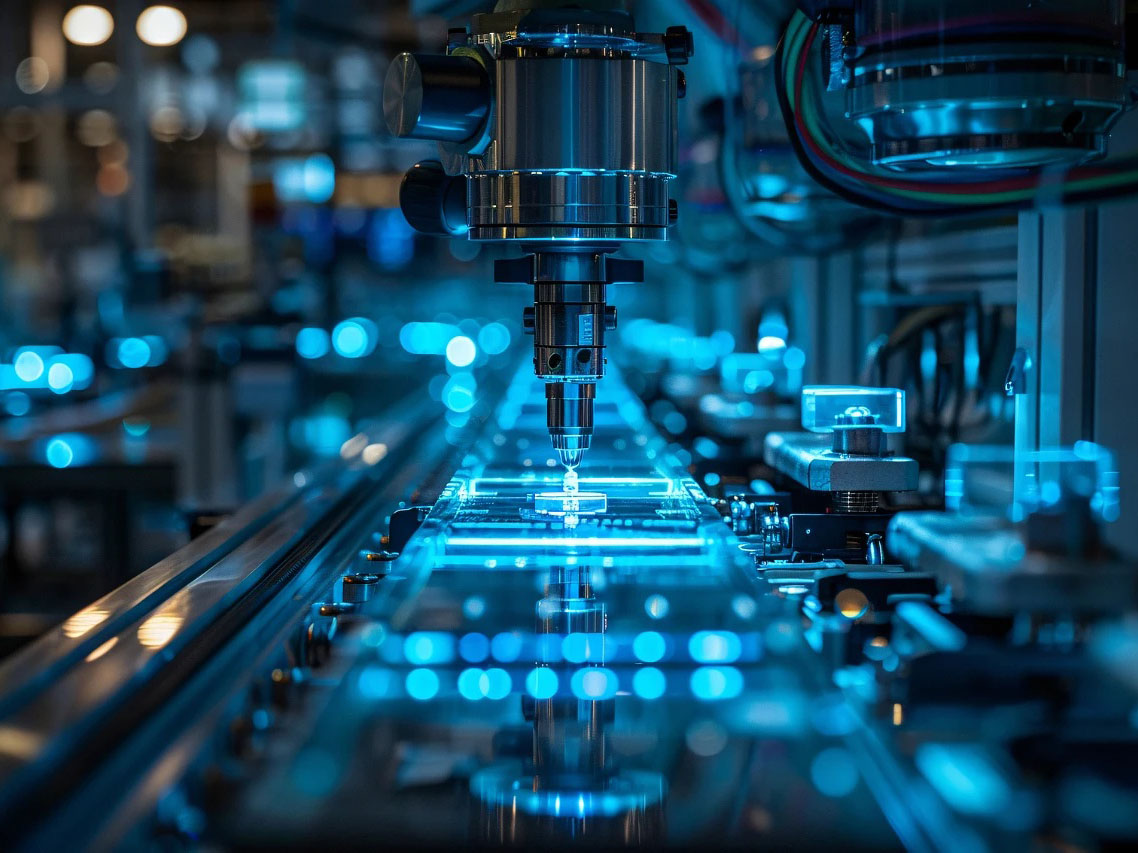

HONPINE keeps up with the era of Industry 5.0 and better serves human-machine collaboration through precision transmission technology

The concept of Industry 4.0, which corresponds to Industry 5.0, first appeared in Germany. In short, Industry 4.0 is to promote industrial transformation through information technology. It is an intelligent industrial era based on the Internet of Things, big data, artificial intelligence, etc. 5G technology, known as the "new engine of digital economy", is a product that closely fits the core concept of Industry 4.0 and is recognized by the world.

Some elements that were ignored in Industry 4.0 (such as people) and factors that were not strengthened enough (such as green and resilience) have been reflected and valued in Industry 5.0. Industry 5.0 is an initiative for manufacturing and social development trends that advocates "artificial intelligence 2.0" at the technical level and "society 5.0" at the social development level. Industry 5.0 represents a reflection on the current smart manufacturing or Industry 4.0, in order to establish a trend that leads the further development of smart manufacturing.

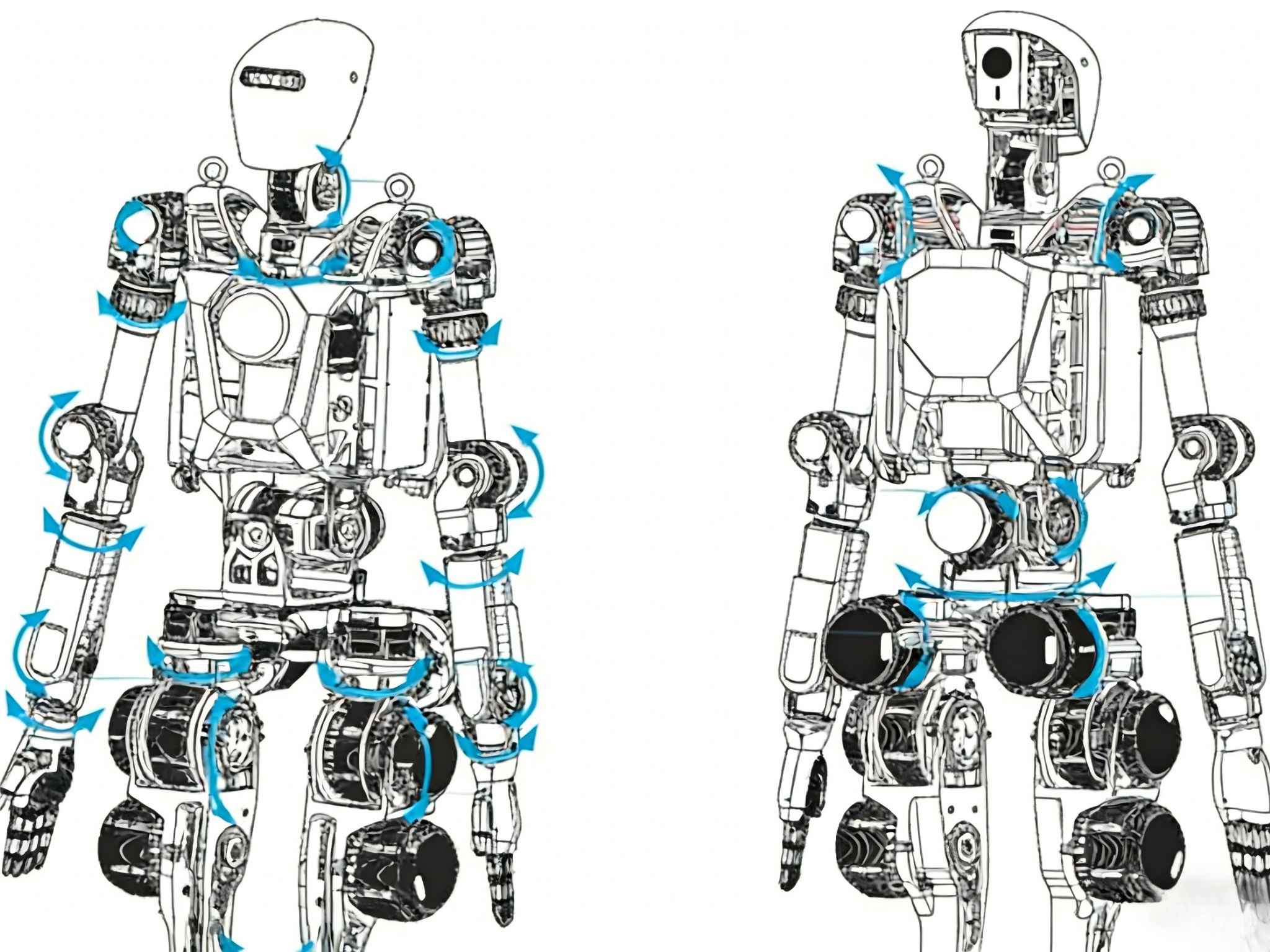

The industry has started a new round of transformation characterized by digitalization and greening, which has put forward higher requirements for the relationship between people and machines. On the one hand, machines need to be more "human-like" and have similar learning abilities as human workers to achieve a high degree of flexibility; on the other hand, they need to better "serve people". Workers must be the core of the new manufacturing scene in the future, and the operation of machines must be completely subject to human will and in line with human habits.

In order to maximize the effectiveness of human-machine collaboration, the core lies in two-way cognitive alignment, that is, ensuring that the cognitive information of machines and humans in task execution is consistent. Through multi-dimensional cognitive capabilities, such as perception, reasoning, decision-making and learning systems, combined with tools such as knowledge graphs to study interactive perception, task planning and other fields, it can effectively promote the optimization of human-machine collaboration. In addition, cognitive empowerment can not only enhance the decision-making ability of machines, but also reversely improve the cognitive ability and efficiency of humans in complex operations, and promote the further development of intelligent manufacturing, especially in the era of Industry 5.0.

The interactive perception between robots and humans is divided into the following three aspects

Machine-to-human perception: Emphasis on improving the ability of machines to recognize human intentions, emotions, and fatigue, and using multiple perception channels (such as EEG signals, EMG signals, eye movements, and facial expressions) for data collection and analysis. This allows machines to understand and respond to human needs more accurately, thereby improving the efficiency and accuracy of human-machine collaboration.

Human-to-machine perception: Discusses the challenges that operators may face in understanding the intentions of machines due to factors such as cognitive load, time pressure, and inconsistency of multi-channel information. Feedback mechanisms such as vision, hearing, and touch help operators better understand and predict the behavior of machines.

Multimodal data fusion: By combining signals from different sensors (such as vision, touch, and voice), the perception of intentions and states by both machines and humans can be enhanced, improving the efficiency and accuracy of collaborative tasks.

HONPINE's value concept in the era of Industry 5.0

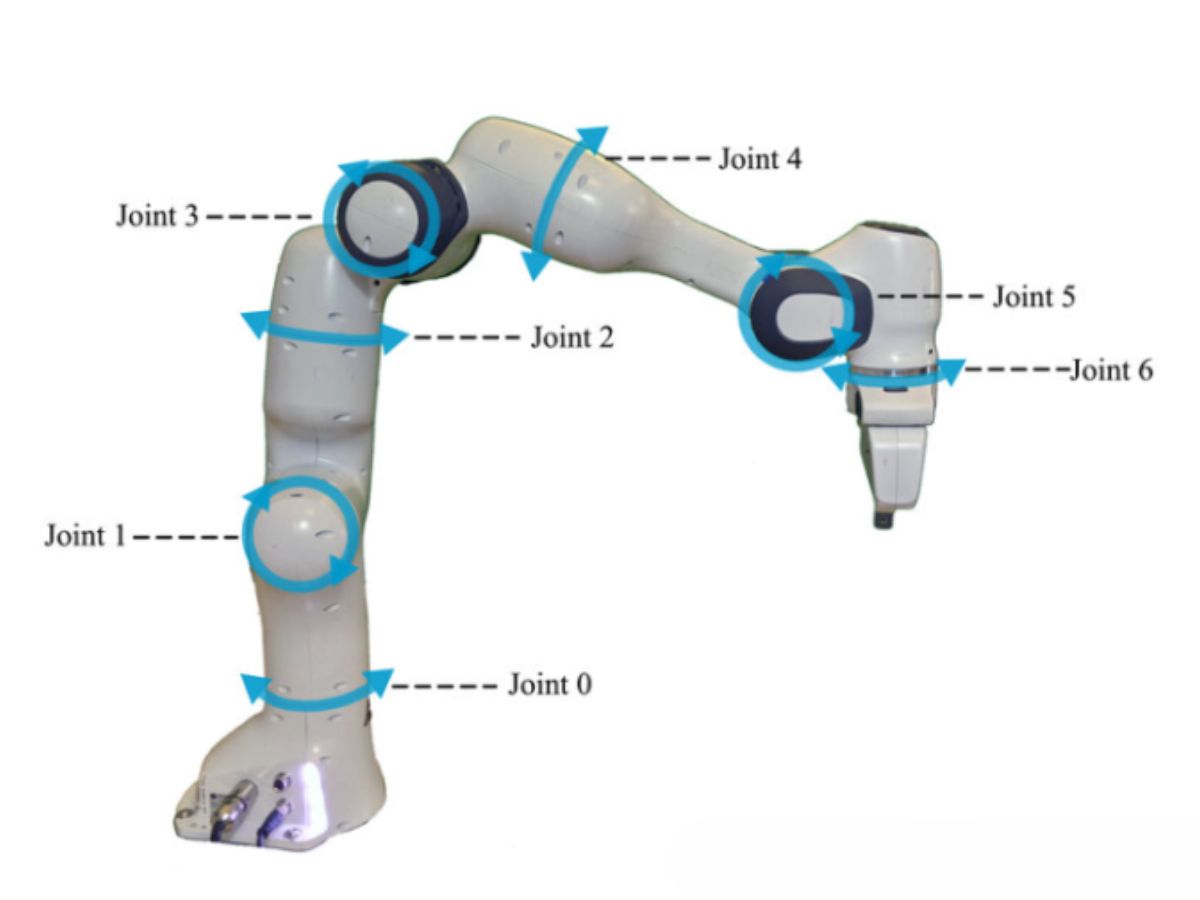

Honpine's concept is advancing steadily and keeping up with the trend of the times. The joint is the heart of the robot. HONPINE is committed to the technical research and development of precision transmission and intelligent joints. It can provide solutions for the research and development of robotic arms and other precision equipment in the era of Industry 5.0.

HONPINE's business philosophy is as follows

Technological innovation: Deeply cultivate the field of precision transmission and intelligent joints

Value leadership: Practice the concept of humanistic manufacturing

Ecological co-construction: Promote the upgrade of intelligent manufacturing with partners

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand