Robot Joint Motors Empower Robots with Flexible Movement in Multiple Degrees of Freedom

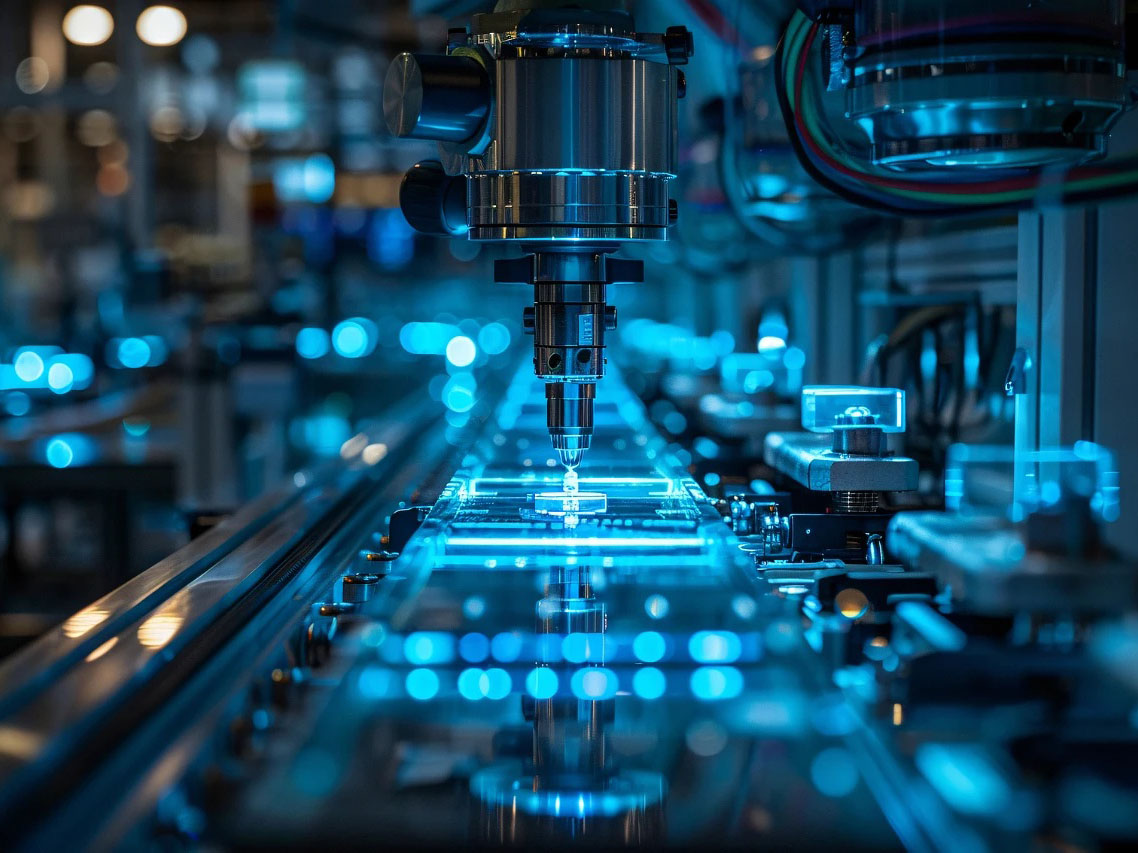

Robot Joint motors can be freely combined to form multi-degree-of-freedom (DOF) robotic arms and serve as the internal framework for service robots, breaking the industry's conventional product design paradigms. They not only meet performance requirements but also foster innovation within the sector. For instance, the smallest models can be applied in gimbals and drones, while the largest models are suitable for humanoid robots and robotic arms. Applications span industrial robots, civilian service robots, specialized robots, machining industries, precision instruments, transportation vehicles, and medical equipment.

Robot joint motors determine the fundamental number of a robot's degrees of freedom.

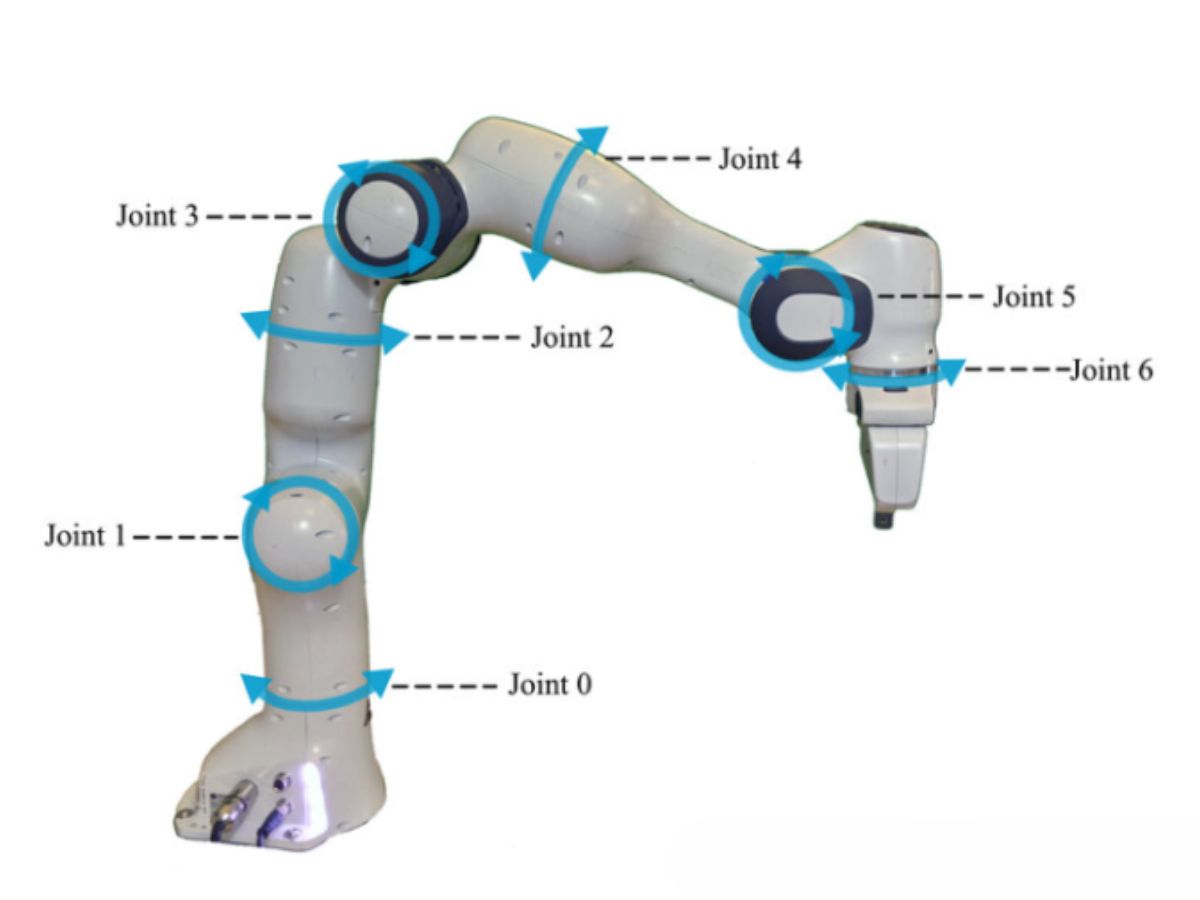

Each robot joint motors typically corresponds to one degree of freedom. For example, a 6-DOF industrial robot requires six harmonic drive joint motors. Bionic robots may need 20 or more DOFs, relying on more compact, high-torque joint motors. SCARA robots generally require four degrees of freedom.

What Are a Robot’s Degrees of Freedom?

Degrees of Freedom (DOF) are a key metric for measuring a robot’s movement flexibility. Simply put, DOF refers to the number of independent directions in which a robot’s joints can move.

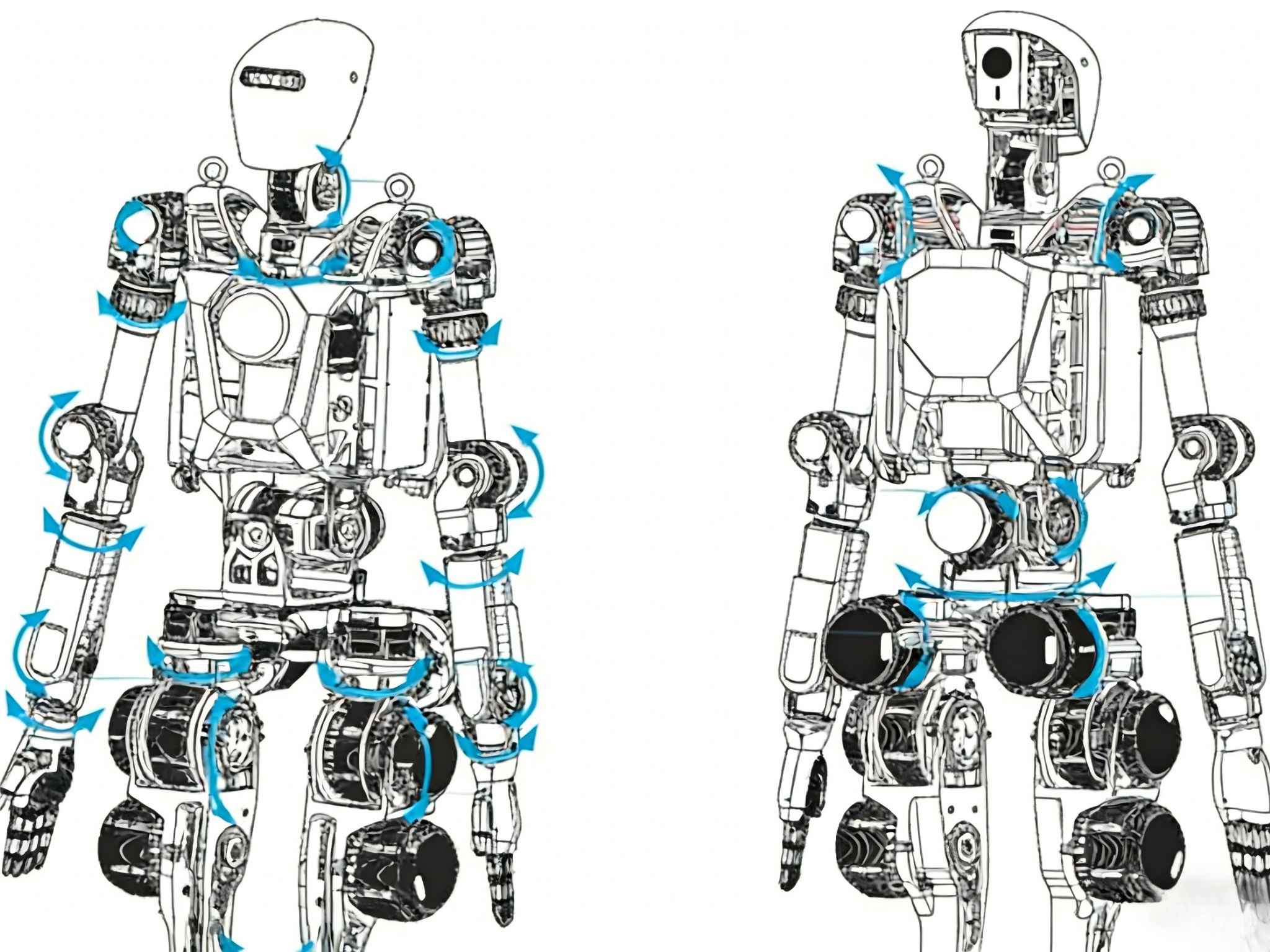

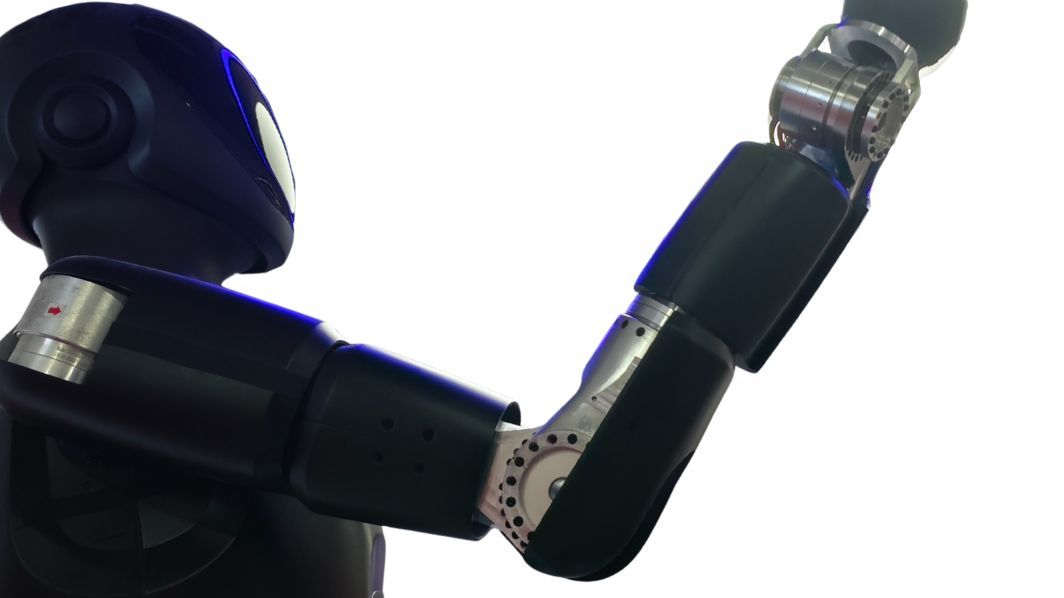

For example, a joint capable of rotating in both horizontal and vertical directions has two degrees of freedom. Different types of joints have varying DOFs. Take a common humanoid robot as an example: the head may have 1–3 DOFs to enable nodding and turning; the arms typically have more DOFs—the shoulder joint usually has 3 DOFs for forward/backward, left/right, and rotational movements, the elbow joint generally has 1–2 DOFs, and the wrist joint has 2–3 DOFs, allowing the arm to perform complex actions like reaching, grasping, and rotating objects. The hip joint in the legs usually has 3 DOFs, the knee joint has 1 DOF, and the ankle joint has 2 DOFs, enabling walking, running, and leg lifting.

Joint motors are crucial for humanoid robots.

Robotic joints must be powerful enough to withstand the reactive forces generated by high-intensity actions like lifting objects, running, and jumping, yet they cannot be too large or heavy, as this would reduce agility and increase power consumption. In essence, joint motors are like human joints—they determine whether a robot can perform tasks accurately and efficiently. They form the foundation for human-like movement, and their performance directly impacts the robot’s effectiveness in practical applications.

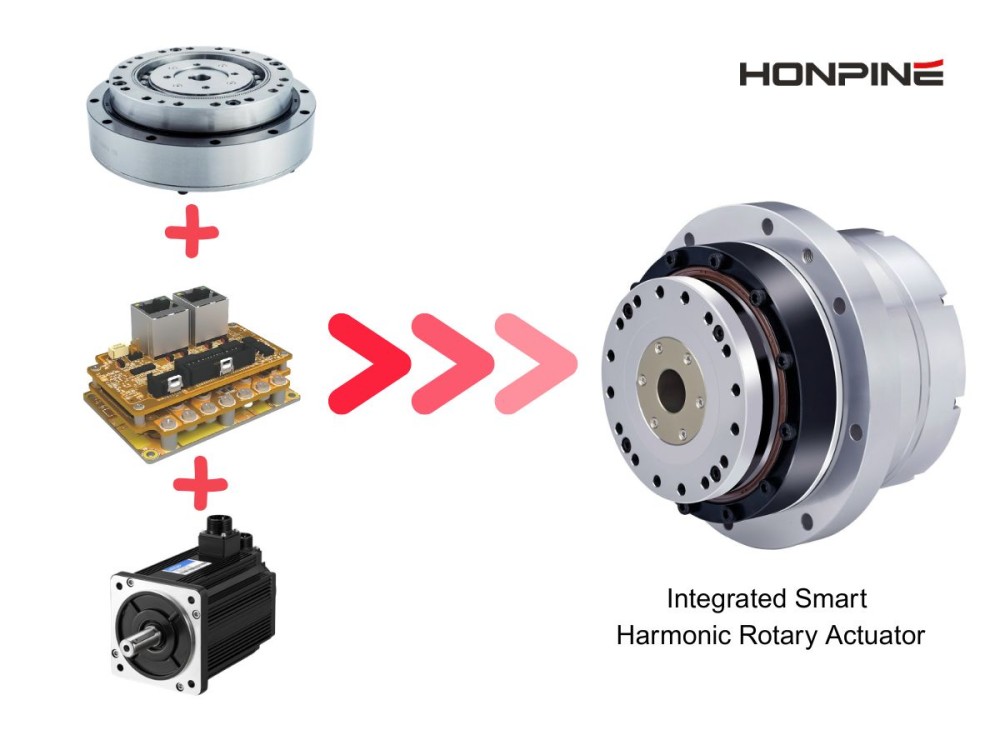

A bulky robot cannot achieve free movement. HONPINE joint motors are compact, highly integrated, precise, and stable in performance. Currently, HONPINE joint motors have become the core power components for robots, specialized robots, and humanoid robots.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand