A Complete Guide to Choosing Single-Encoder vs. Dual-Encoder Robot Joint Actuators

In a robot joint, encoders play a role similar to human vision and proprioception. They continuously measure the position and speed of both the motor rotor and the output shaft, feeding this information back to the controller to form a precise closed-loop control system.

Encoders are also one of the core components of HONPINE joint actuators, directly determining motion accuracy, stability, and safety.

What Does Encoder Resolution Really Mean?

Encoder resolution refers to the smallest detectable change in position—much like the smallest scale on a ruler.

For example, a 17-bit encoder divides one full revolution into 131,072 counts, corresponding to a theoretical resolution of 0.00275°.

However, resolution is not the same as accuracy.

Effective accuracy describes the maximum deviation between the encoder’s reported position and the true physical position, typically specified in arc-seconds.

Key takeaway:

High resolution does not necessarily mean high accuracy.

When selecting an encoder, engineers must look beyond bit count and carefully evaluate its absolute accuracy specification.

Why High-End Robots Prefer Dual Encoders?

Single-Encoder vs. Dual-Encoder Architecture

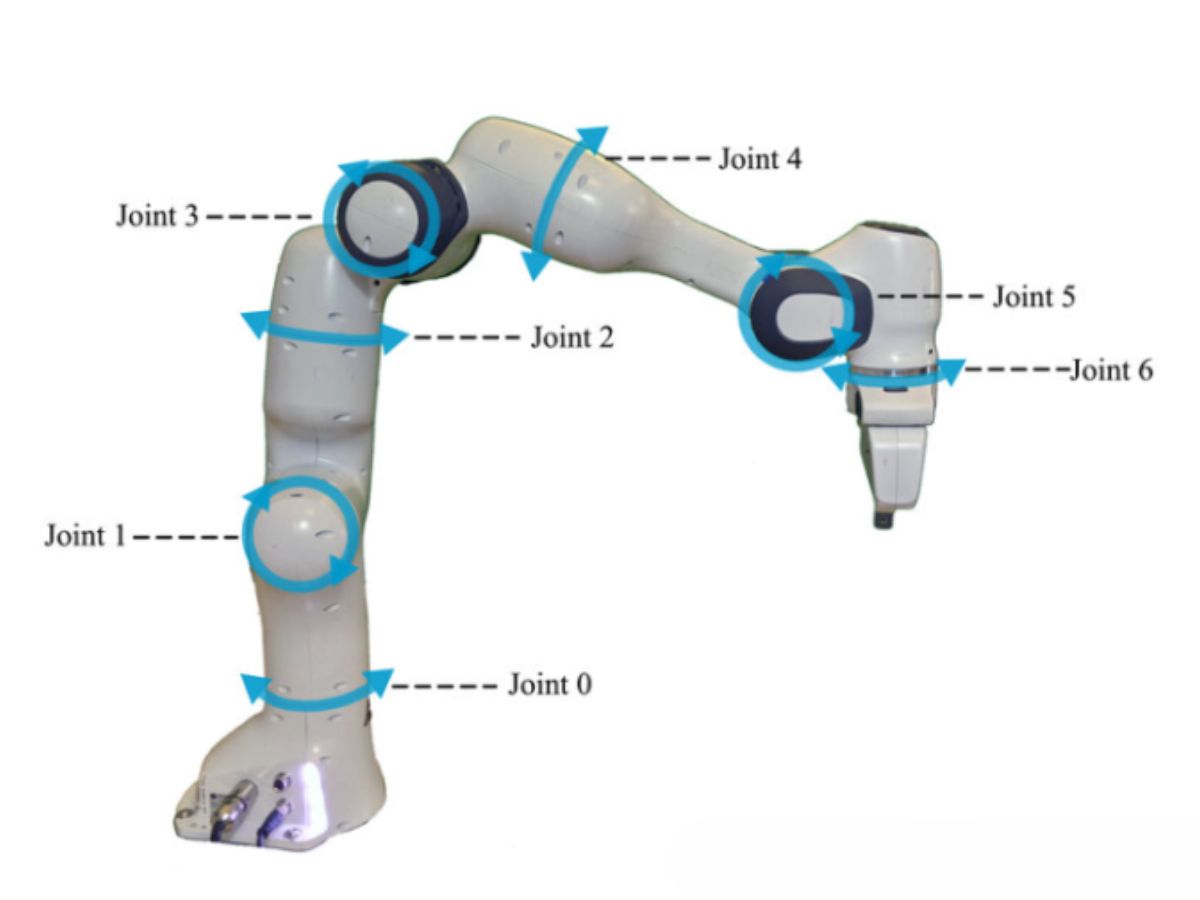

Motor-side encoder (high-speed side):

Mounted on the servo motor shaft, typically an incremental encoder.

It is primarily used for the inner control loops—current and velocity control.

Output-side encoder (low-speed side):

Mounted on the reducer output, and must be an absolute encoder.

It directly measures the joint’s true output position.

Key Advantage

With an output-side encoder, the control system can compensate for transmission errors, including reducer backlash, torsional compliance, and elastic deformation. This dramatically improves end-effector repeatability and positioning accuracy.

More importantly, it decouples control error from mechanical error.

The controller can clearly determine whether a deviation originates from command execution, motor response, or the mechanical transmission itself—enabling targeted, model-based control strategies.

Application Differences: Single vs. Dual Encoders

Single Encoder Systems

Thanks to their simpler structure and lower cost, single-encoder actuators dominate applications where absolute precision and interaction compliance are not critical, such as:Standard material handling,Palletizing,Spot welding,Repetitive point-to-point motion

In these scenarios, cost-performance efficiency is the primary consideration.

Dual Encoder Systems

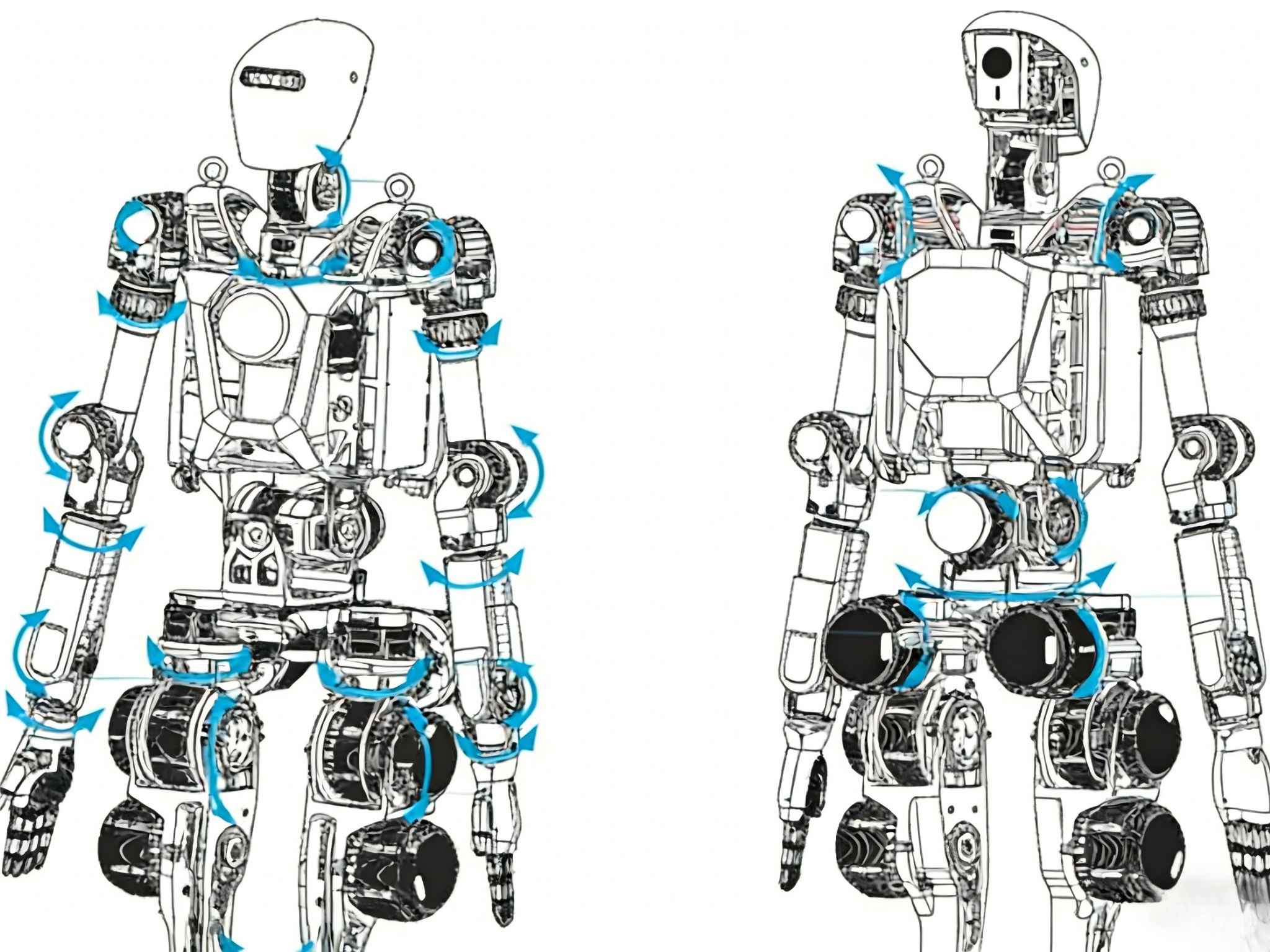

Dual encoders have become an undisputed standard in high-end robotics.

Medical robots performing delicate surgeries, collaborative robots working alongside humans, and humanoid robots pursuing human-like motion capabilities all rely on dual encoders as a fundamental enabler of their core functions—precision, compliance, and safety.

Here, value creation outweighs cost.

Turning Error Into “Touch”: The Hidden Power of Dual Encoders

The higher-level value of dual encoders lies in a profound shift of perspective.

The angular difference between the motor side and the output side is no longer treated as meaningless “error.” Instead, it becomes valuable insight into the internal state of the joint.

This angular difference directly represents the elastic deformation of the transmission chain, especially within the reducer.

With a known or identified stiffness model, this deformation can be translated into real-time joint torque.

In other words, without expensive torque sensors, the robot joint gains a form of tactile perception. It can sense how much force it is applying to the environment—or how much force the environment is applying to it.

This is precisely why collaborative robots, surgical robots, and humanoid robots almost universally adopt dual encoders. These robots require not only positional accuracy, but also the ability to interact with the world with controlled softness and compliance.

Examples include:

Precision assembly: detecting insertion resistance and automatically adjusting posture

Polishing and grinding: maintaining constant contact force rather than rigid position control

Human-robot collaboration: yielding immediately upon contact with a human body

Dual Encoders Make Joint Actuators More Reliable and Safer

In high-end applications, reliability is mission-critical.

Dual encoders inherently provide redundancy and cross-validation. If the motor-side encoder indicates that the target position has been reached, while the output-side encoder shows otherwise, the system can instantly identify an abnormal condition.

This may indicate:Encoder malfunction,Transmission slippage,Gear wear or damage within the reducer

Such real-time, online fault diagnosis and early warning is impossible in single-encoder systems.

In scenarios involving close human interaction or long-term high-load operation, this capability is not merely a performance upgrade—it is a cornerstone of functional safety.

From Single to Dual Encoders: A Fundamental Evolution

The evolution from single-encoder to dual-encoder architectures represents a profound transformation—from open-loop execution to closed-loop physical perception.

Single-encoder control operates on an idealized, simplified mathematical model.

Dual-encoder control governs a real physical system—one with elasticity, friction, wear, and imperfections.

For the first time, the robot can understand and adapt to the physical world’s inherent non-idealities.

This is not simply a difference in sensor count; it is a dividing line in robotic intelligence. It determines whether a robot remains a mechanical arm that blindly repeats predefined trajectories, or becomes an intelligent agent capable of perceiving its environment, adapting to change, and interacting safely with humans.

In the future, whether a robot possesses this dual-perception system may well become a defining benchmark of its capability and value.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand