How to Choose the Best Robot Joint Module Supplier?

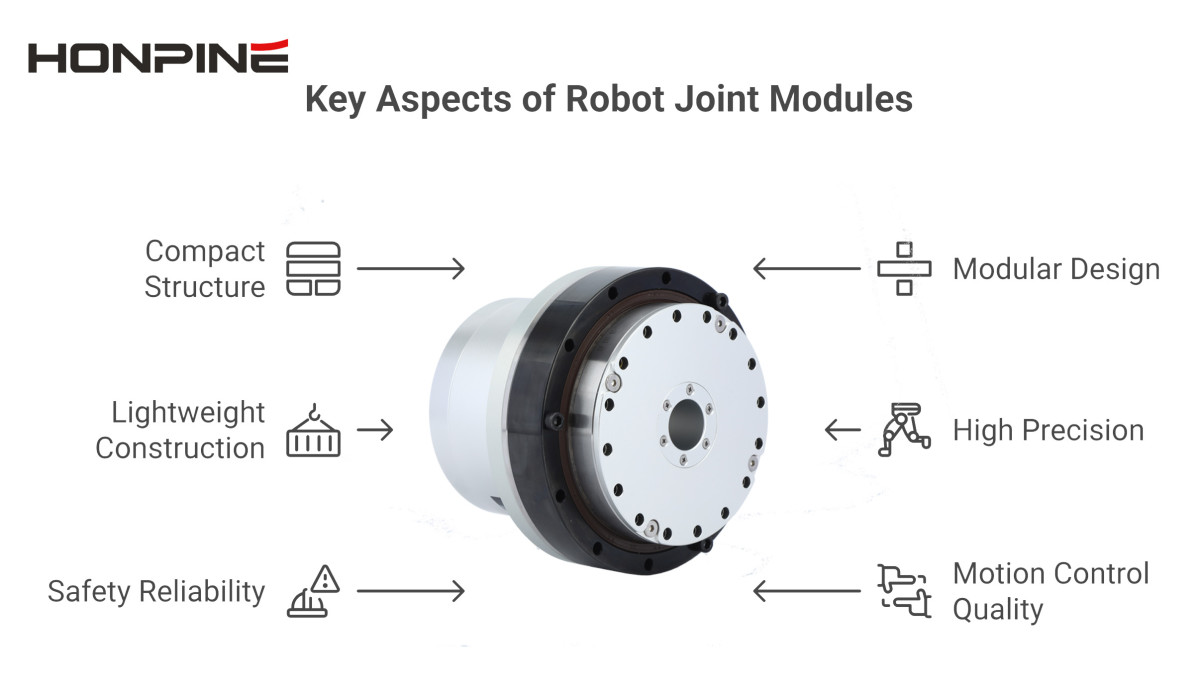

Robotic arms play an important role in various fields, such as intelligent manufacturing, medical devices, and aerospace. As the core component of the robotic arm, the joint module features a compact structure, modular design, lightweight construction, high precision, and safety reliability. These joint modules drive the robotic arm's rotational motion, directly affecting the system's motion control quality and accuracy. Optimizing joint module design and performance can further improve the robotic arm's motion control accuracy, stability and response efficiency to meet demanding requirements across different applications.

Joint modules are mainly divided into two types: planetary joint modules and harmonic joint modules

Planetary Joint Module

The planetary joint module serves as a core component of the robot power system. Compared with harmonic joint modules, it offers a smaller reduction ratio, higher output speed, and greater rigidity, though with slightly lower overall output accuracy. By integrating planetary reducers, frameless torque motors, brakes, encoders, drivers and other components, it achieves significant optimization in volume and weight for precise joint motion control. This results in greater torque output with smaller size and lighter weight. Our planetary joint modules typically support a wide voltage range (DC24V-DC48V) and can be customized to meet specific requirements.

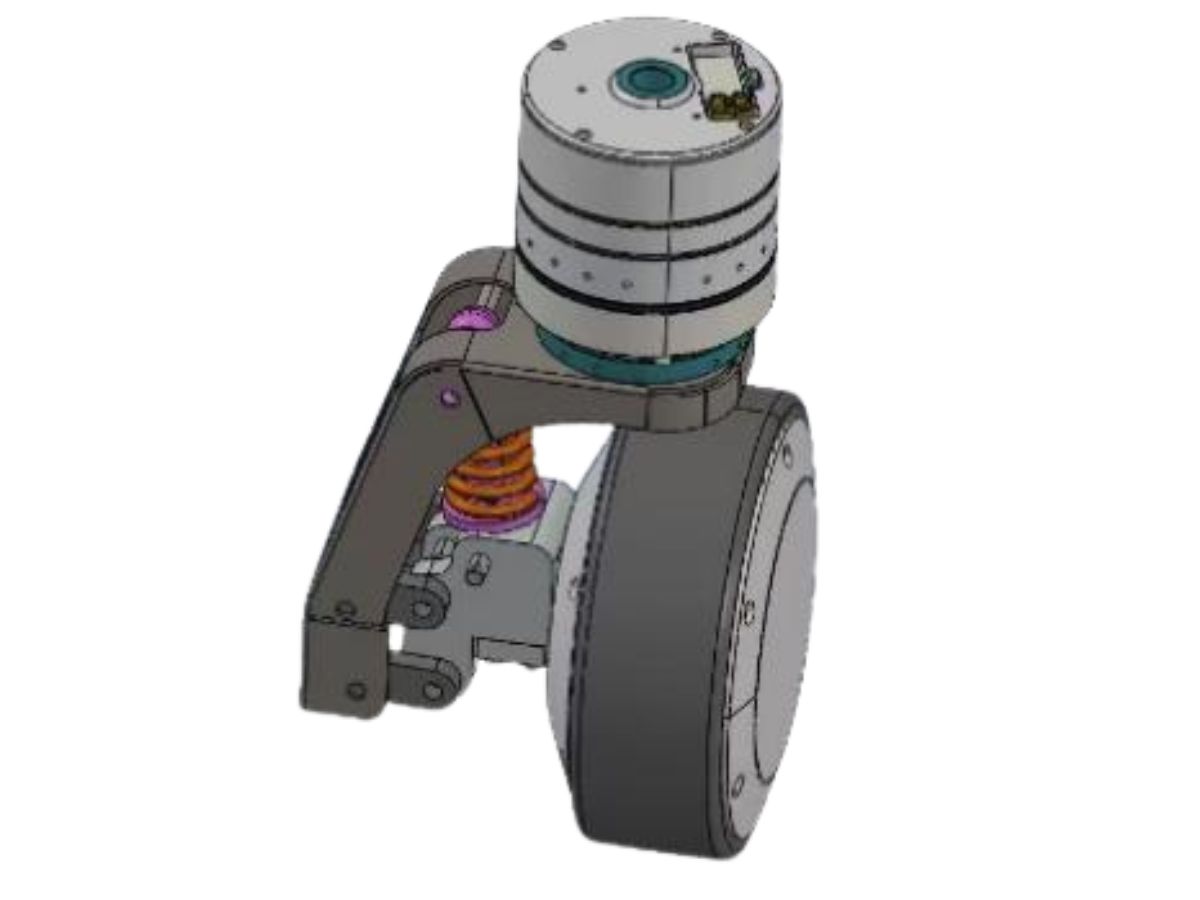

In logistics AGV (Automated Guided Vehicle) applications, the planetary joint module can be structurally modified and highly integrated with wheels to form hub motors (also called servo wheel modules).

Harmonic Joint Module

The harmonic joint module integrates harmonic reducers, frameless torque motors, brakes, encoders, drivers and other components, achieving excellent volume and weight optimization for precise joint motion control. It delivers greater torque, higher precision, more compact size and lighter weight. Customization is available to meet specific needs, with standard modules supporting DC24V-DC48V voltage ranges.

As a core component in robotics, joint module technology continues to advance, driving progress in special robots and humanoid robots toward greater flexibility and wider applications. Beyond robotics, these modules are also widely used in semiconductor equipment, photovoltaic systems, precision medical devices, 3C equipment, optical instruments and other fields.

How to Select Joint Modules for Specific Applications

Choosing the right joint modules requires considering multiple factors. HONPINE provides dedicated technical support for each customer, helping evaluate:

Load capacity and torque requirements

Range of motion

Size and weight constraints

Motor type selection

Transmission efficiency

Encoder accuracy

Communication protocols

Closed-loop control

Voltage compatibility

Energy efficiency

We also offer customization services for color, installation methods, waterproof ratings and other special requirements based on your robot design.

Common Mistakes in Selecting Humanoid Robot Joint Modules

During the selection process for humanoid robot joint modules, some common errors may lead to mismatched performance or even affect the robot's overall functionality and service life.

Neglecting Load Capacity and Torque Requirements

Underestimating the required load capacity and torque can cause premature module failure. For example, in industrial applications with frequent material handling, joints must sustain heavy loads continuously. Statistics show that over 30% of selection-related failures stem from insufficient torque capacity.

Overemphasizing Precision Without Considering Cost Efficiency

High-precision modules often come at significantly higher costs. For applications like home service robots where ±0.5°-±1° accuracy suffices, insisting on ±0.1° precision unnecessarily increases both initial and maintenance costs, as precision components are more susceptible to wear.

Ignoring Environmental Adaptability

Harsh environments (high temperature, humidity, dust) greatly impact joint module performance. Without proper environmental protection, modules in high-temperature settings may experience accelerated aging of electronic components and lubricants, while unprotected metal parts in humid conditions can rust. Environmental factors account for about 25% of field failures.

Overlooking Modularity and Maintenance

Focusing solely on performance while neglecting modular design can lead to difficult and costly repairs. Modular joint modules typically reduce repair time by over 60% compared to non-modular designs, significantly improving operational efficiency.

Advantages of HONPINE Joint Modules

Compact Design

Our ultra-lightweight design reduces weight by one-third, significantly lowering operational energy consumption.

High Torque Density

With torque density (torque output per unit mass/volume) twice that of comparable products, our modules deliver exceptional power output efficiency.

Robust Performance

Meeting industrial standards with automotive-grade components, our modules feature anti-static and anti-vibration properties.

Modular Architecture

The system combines six modular components across three product series, adapting to various scenarios while simplifying production and improving efficiency.

Why Choose HONPINE Robot Joint Module?

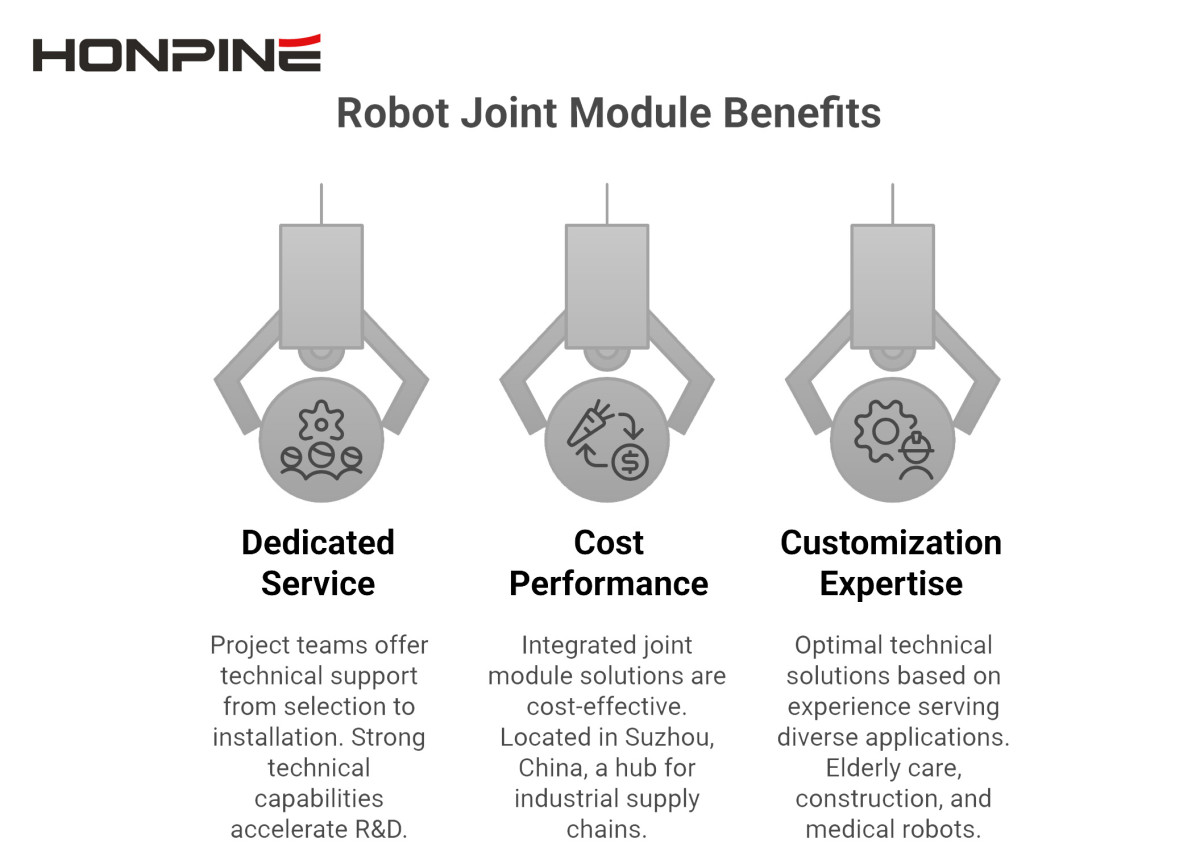

Dedicated One-to-One Service

As an integrated manufacturer covering R&D, production and sales, we assign dedicated project teams to provide comprehensive technical support from selection through installation. With humanoid robot development still in early stages, choosing a supplier with strong technical capabilities can accelerate your R&D cycle and competitive positioning.

Exceptional Cost Performance

Many clients initially approach us for individual components like harmonic reducers, but after evaluation, most choose our complete joint module solutions. Located in Suzhou, China - a hub for industrial supply chains - we offer the most cost-effective integrated joint module solutions.

Customization Expertise

With extensive experience serving diverse applications including elderly care robots, construction robots, industrial robots, special robots and medical robots, we provide optimal technical solutions based on proven experience.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand