Cup-Type Harmonic Drive Effectively Addresses Short Lifespan Issues of Harmonic Drivers

In industrial robots, harmonic drives are widely used in joint transmission systems due to their high precision, high torque transmission, and smooth operation. These characteristics make harmonic drives an ideal choice for applications requiring precise control and high performance, such as industrial robots, aerospace equipment, and precision instruments. To solve the problem of fatigue failure and short lifespan of the flexspline—a critical component in harmonic drives—HONPINE has designed a cup-type harmonic drive.

The Importance of the Flexspline in Harmonic Drive Construction

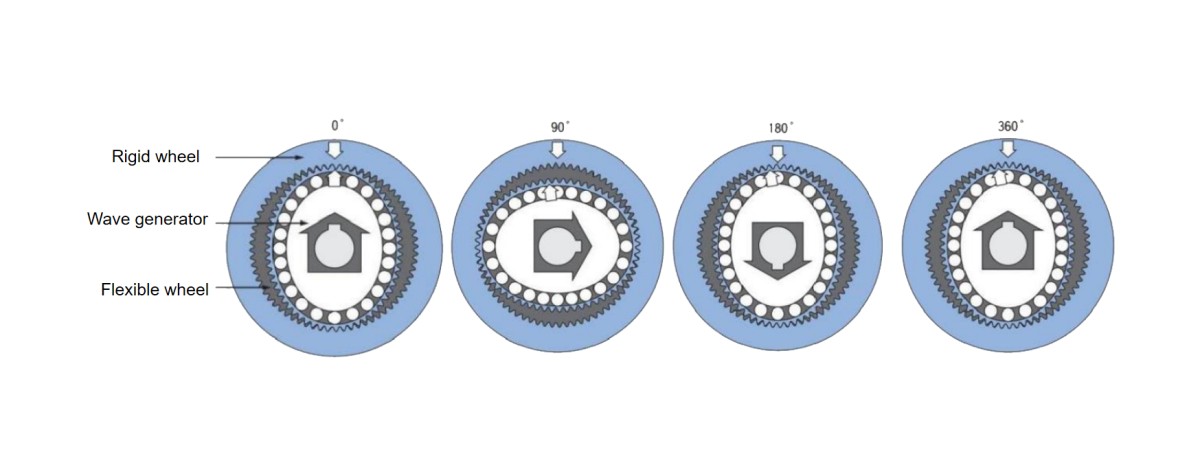

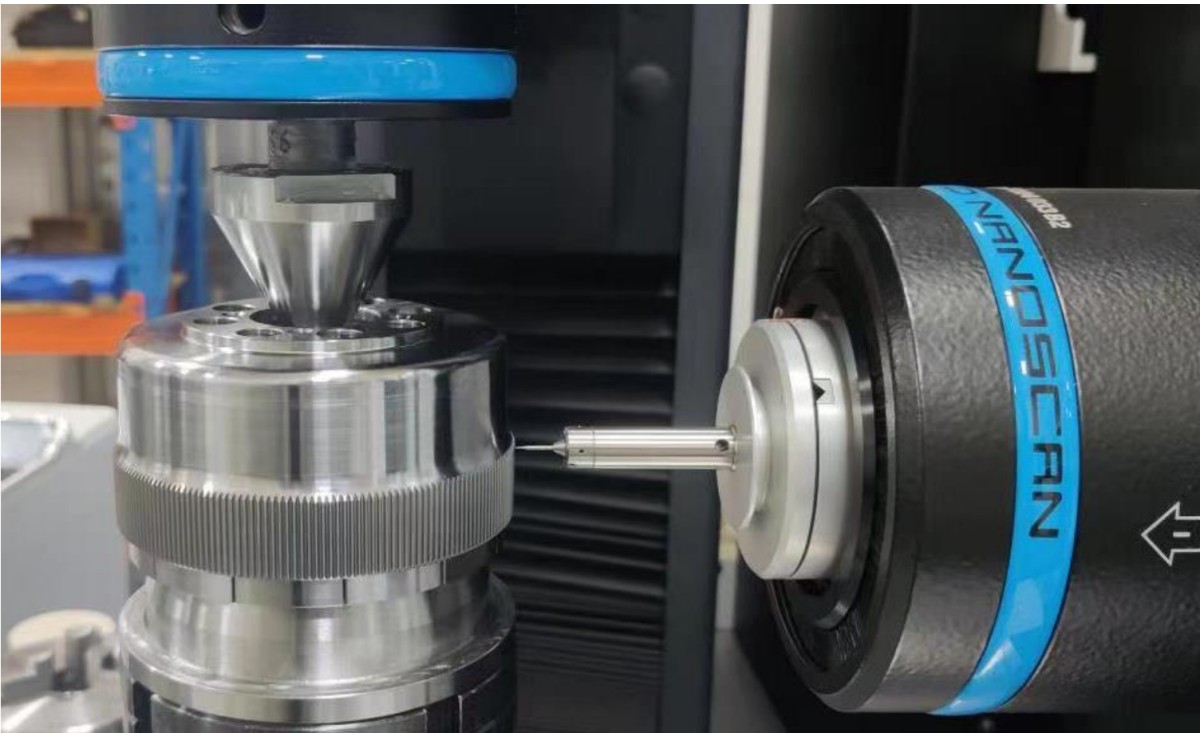

Harmonic transmission relies on the elastic deformation of the flexspline, making it the most stressed and fatigue-prone component. In other words, the lifespan of the flexspline determines the operational life of the harmonic drive. HONPINE optimizes structural parameters to effectively control the maximum stress on the flexspline under both no-load and loaded conditions while achieving the shortest possible barrel length. This ensures optimal performance, reduces fatigue failure risks, and extends service life.

What is a Cup-Type Harmonic Drive?

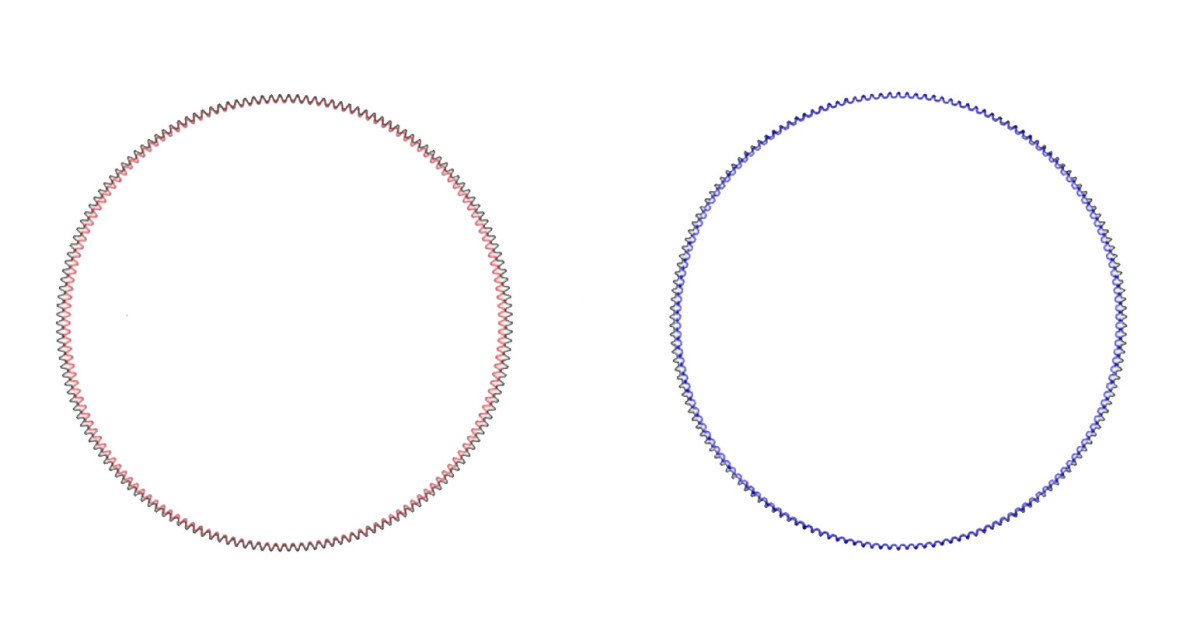

The flexspline in harmonic drives mainly comes in two shapes: cup-type and hat-type (hollow). The cup-type flexspline, resembling a cup with a recessed center, is commonly used in harmonic drives, robotics, precision machinery, and aerospace mechanisms for motion control and power transmission.

The cup-type flexspline is typically connected to other mechanical components via bolts or pins. The exact connection method depends on the harmonic drive's design and manufacturing standards, but it usually features pre-drilled holes or interfaces at the rim for secure fastening.

Advantages of Cup-Type Harmonic Drives

Also known as a double-circular-arc harmonic drive, it provides superior meshing performance and higher contact ratio between the circular spline and flexspline.

Compact and lightweight, making it ideal for industrial robots with space constraints.

HONPINE R&D analysis confirms that the double-circular-arc tooth profile outperforms traditional involute gears in stress distribution and deformation resistance.

Optimized through orthogonal testing based on feedback from global customers, enhancing performance and stability.

Rigorous quality validation ensures compliance with market demands and reliability.

Recommended HONPINE Cup-Type Harmonic Drives

FSG Series – Easy-Installation Strain Wave Gear for Robot Arms and Sealed Rotary Tables

FSD Series – Compact Cup-Type Harmonic Gear for Aerospace, Robotics, and Semiconductor Equipment

FCG-AJ – Series – High-Torque Heavy-Doad Cup-Style Strain Wave Gear

HONPINE’s cup-type harmonic drives offer longer lifespan, higher precision, and greater durability, making them a superior choice for high-performance automation and robotics applications.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand