HONPINE Harmonic Drive’s Backdriveability Enables Technological Breakthroughs in Multiple Fields

What is Backdrivability in Integrated Joint Modules?

In academia, backdrivability is defined as the ease of driving an entire joint by applying force at the load end. Y. Kawai et al. describe joint drive performance using a bidirectional power transfer matrix, where backdrivability and forward drivability are characterized by the ratio of acceleration to external force at the motor and link ends, respectively.

The Importance of Harmonic Drives in Achieving Backdrivability

Due to the harmonic drive’s inherent transmission characteristics, integrated joints inevitably exhibit both forward and reverse efficiency. Transmission efficiency loss stems from friction during operation, influenced mainly by load, speed, and temperature—with load being the most significant factor. Additionally, the harmonic drive’s unique flexible meshing mechanism results in different force distributions between the circular spline and flexspline during forward/reverse motion, leading to distinct efficiency models.

Key Applications Requiring Harmonic Drive Backdrivability

Industrial Robots (welding, palletizing, machine tending)

Demand both rigidity and backdrivability, often requiring feedforward compensation to counteract hysteresis.

Collaborative Robots (assembly lines, medical assistance)

Allow direct human guidance; low-friction backdrivability is critical for safe operation.

Surgical Robots (minimally invasive surgery, vascular interventions)

Require ultra-high precision and backdrivability to enable delicate haptic feedback for surgeons.

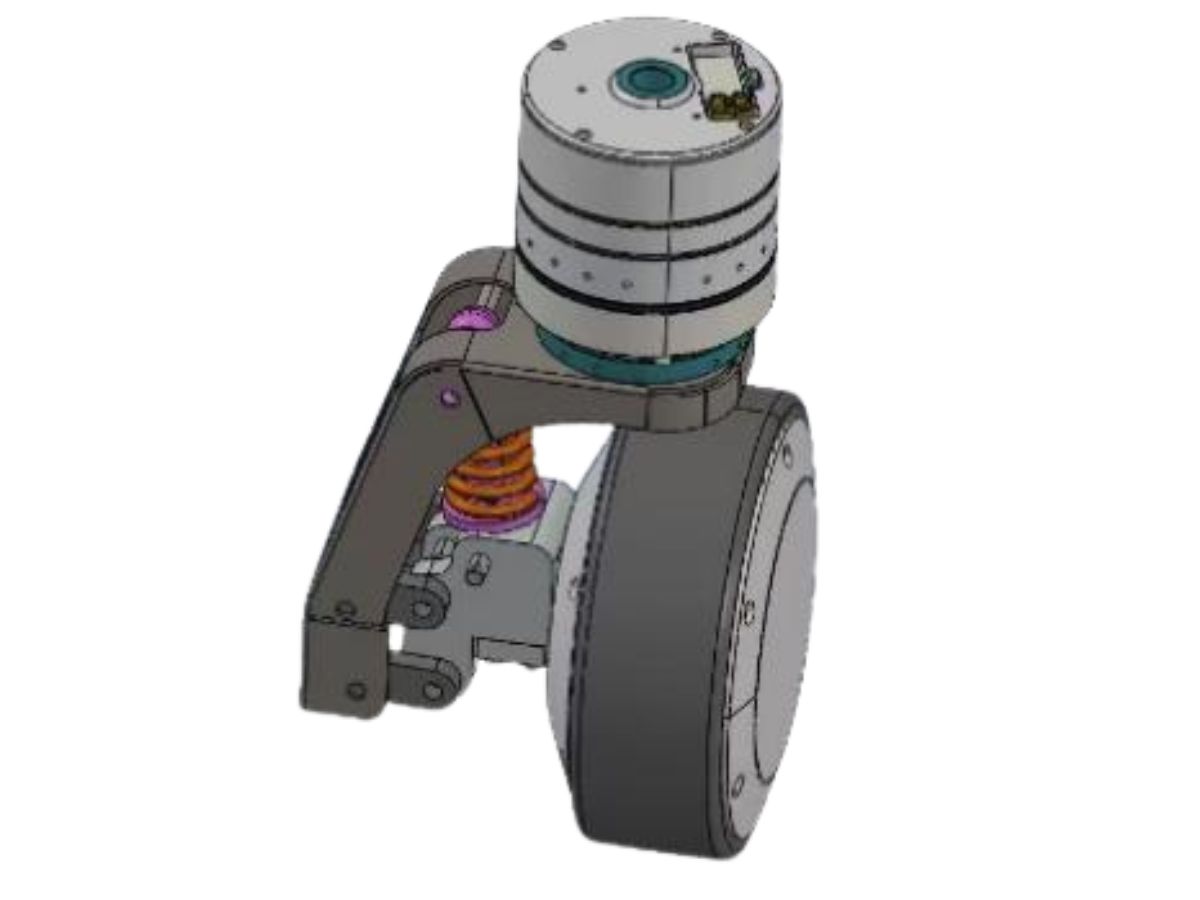

Quadruped/Bipedal Robots

Backdrivability enables rapid recovery from falls, as seen in dynamic locomotion.

Space Robots (satellite servicing, lunar exploration)

Must maintain controllable backdrivability even in vacuum conditions.

Micro Harmonic Drives (pipe inspection, drug delivery)

Backdrivability allows deformation-driven navigation in confined spaces.

Conclusion

Backdrivability in harmonic drives is a key enabler for modern robotics—enhancing flexibility, intelligence, and efficiency. It is indispensable in collaborative robots, medical robotics, and dynamic mobile robots.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand