Is the Harmonic Drive Reducer too flexible? HONPINE Harmonic Drive Actuator achieves 3× higher rigidity!

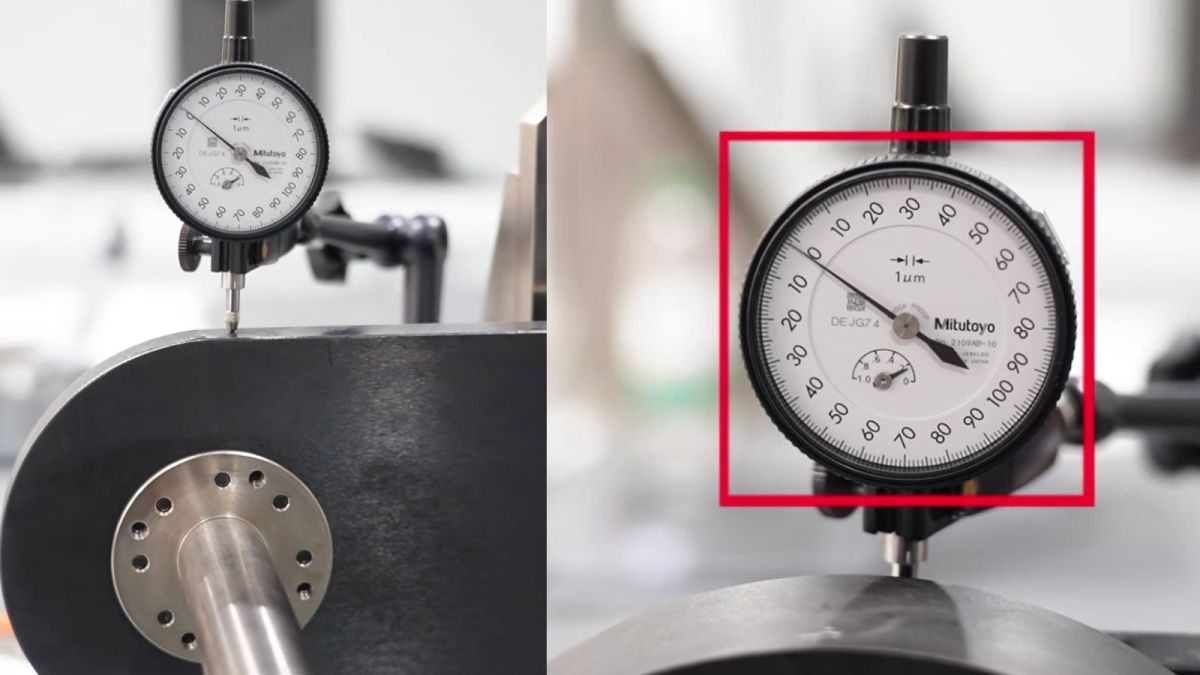

Still struggling with low rigidity and torsional deformation in harmonic drive reducers? HONPINE has developed the upgraded HAT-G Series Rotary Actuator to address this industry-wide pain point. Standard reducers tend to deform and rebound easily under load, while our actuator—enhanced by a specialized software algorithm—boosts rigidity by more than three times. Under the same force, the dial gauge barely moves. A high-precision encoder is also available, delivering positioning accuracy of ≤5 arc-seconds.

Why Harmonic Drive Reducers Often Cause Rigidity Problems?

The flexspline in a harmonic drive reducer is a thin-wall metallic elastic component supported in a cantilever structure. It is connected to the shaft or coupling on one side, while the other end remains free to deform. This structure is compact and allows the flexspline to generate the required elastic deformation, but it also leads to the inherent drawback of limited rigidity.

To address this issue, HONPINE has developed its latest Harmonic Drive Actuator, offering significantly enhanced rigidity and precision.

Rigidity Characteristics of Standard Harmonic Drives

In typical harmonic drive reducers, applying a force to the output end often results in noticeable torsional deformation. Once the force is removed, the reducer immediately springs back to its original position.

With HONPINE’s specialized software algorithm, rigidity increases instantly by three times. When the same force is applied, the dial gauge shows almost no movement. Our harmonic drive actuator can also be equipped with a high-precision encoder, achieving positioning accuracy better than 5 arc-seconds.

Features of the HONPINE Harmonic Drive Actuator

The HONPINE harmonic drive actuator integrates a harmonic reducer, frameless torque motor, and optional hollow optical encoder and electromagnetic brake. It delivers:

High tilting rigidity

High torque capacity

Smooth operation

Zero backlash

Low noise

Over 15,000 hours of service life

Maintenance-free operation with no lubrication replacement

A hollow shaft for routing cables and pneumatic lines

Easy installation compatible with standard drivers—plug-and-play convenience

If you are facing rigidity issues with a harmonic drive actuator, feel free to contact us.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand