Advantages of Harmonic Gears in Robotics

In the rapidly evolving world of robotics, precision and efficiency are paramount.Thanks to their compact structure, high reduction ratio, high positioning accuracy, and high torque capacity, harmonic gears have become the preferred motion control solution for applications such as robotic arms and humanoid robots, where space and weight are critical factors.

What Are Harmonic Gears?

Harmonic gears, also known as strain wave gears, are a unique type of gear mechanism that offers distinct mechanical advantages.Unlike traditional gears, harmonic gears use a flexible gear that deforms to mesh with a rigid circular spline.This design enables high gear reduction ratios, high precision, and compact form factors.

The core components of a harmonic gear include the wave generator, the flexspline, and the circular spline.The wave generator is an elliptical cam fitted inside the flexspline, causing it to deform and engage with the circular spline.As the wave generator rotates, it moves the flexspline against the circular spline, creating precise motion transmission.

Typical Combinations of Harmonic Gears with RV Reducers and Planetary Gearboxes

Harmonic Gears and RV Reducers

Harmonic gears and RV reducers are the ideal combination for heavy-duty, high-precision industrial robots.In large six-axis industrial robots, the RV reducer provides high rigidity and large torque output, while the harmonic gear ensures flexible and precise motion at the end joints.

Harmonic Gears and Planetary Gearboxes

In collaborative robots (cobots), humanoid robots, and small robotic arms, harmonic gears are best paired with planetary gearboxes.The planetary gearbox serves as the first-stage pre-reduction, lowering the high-speed motor output.The harmonic gear then acts as the second-stage precision reducer, delivering smooth, low-speed, high-torque output.

The Future of Harmonic Gears

In the future, integrated harmonic joint modules will become the dominant trend.

A harmonic joint module combines a harmonic gear, motor, encoder, driver, and housing into a highly integrated, modular robotic joint unit.

With high torque density, lightweight construction, and zero backlash, harmonic joint modules are becoming the first choice for humanoid robots and collaborative robots.

Meanwhile, their modular and intelligent design makes them ideal for the upgrading of industrial robots, effectively reducing R&D, maintenance, and assembly costs.

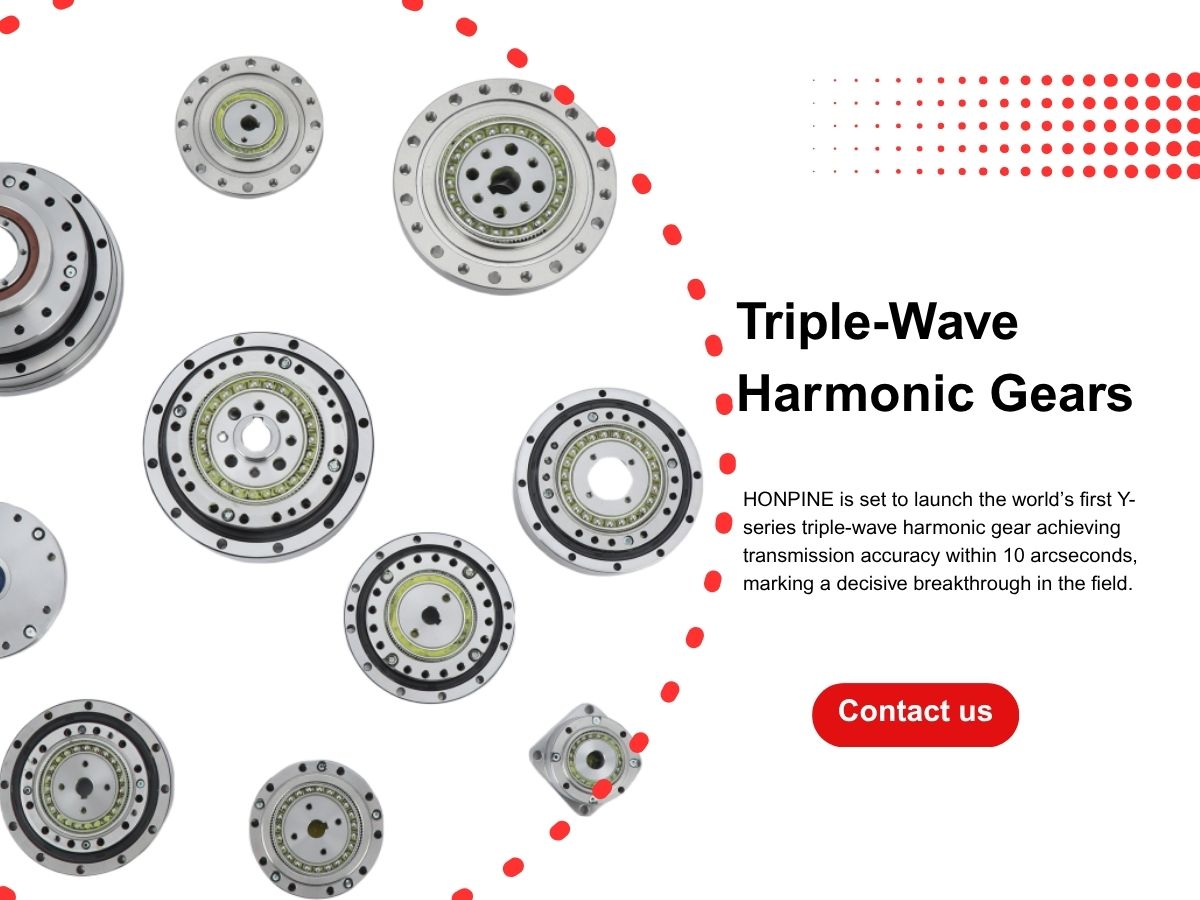

HONPINE Is Redefining the Harmonic Gear Industry

HONPINE offers the most comprehensive range of harmonic gears in China and is consistently investing in R&D for new products.

Our proprietary ultra-fine crystal technology and triple-wave harmonic gears are changing the game in precision motion control.

HONPINE emphasizes both pre-sales and after-sales service.

We provide customers with end-to-end technical support—from product selection to real-world application—to ensure optimal performance under actual operating conditions.At the same time, we have established a comprehensive after-sales response system to quickly resolve any issues that may arise during use.

With strong R&D capabilities and a full-spectrum service system, HONPINE continues to drive innovation and adoption of harmonic gear technology, empowering the intelligent equipment industry toward greater efficiency and advancement.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand