High Precision Planetary Reducer,RV Reducer,Harmonic Reducers for Advanced CNC Milling Applications

CNC milling machines are particularly well-suited for machining parts with complex geometries, precise contours, or requiring multi-axis machining, such as automotive gearbox assemblies, aluminum body structures, and high-precision hydraulic system components. Mainstream harmonic reducers, planetary reducers, and RV reducers each serve distinct functions in the precision transmission systems of CNC milling machines. HONPINE's patented anti-backlash high-precision planetary reducer is also gaining recognition in this field.

Why are precision reducer performance requirements exceptionally high in CNC milling machines?

CNC milling machines not only perform multi-surface machining but in multi-axis versions can even machine from multiple angles and orientations within a single setup, significantly increasing productivity and flexibility. Their high degree of freedom and precision make CNC milling machines indispensable, particularly when machining complex curved surfaces or executing five-axis operations. Precision part measurement and tool calibration are critical during CNC milling. In the automotive industry, component accuracy directly affects vehicle performance and quality.

Performance Requirements for Reducers in CNC Milling Machines

● High Precision Requirements

CNC milling machines typically achieve micron-level machining accuracy, requiring reducers with extremely high transmission precision. For example, a German-brand high-precision milling machine uses a planetary reducer with backlash limited to ≤1 arc-minute, ensuring worktable positioning accuracy of ±0.005 mm.

● High Rigidity Requirements

Milling generates significant cutting reaction forces, requiring reducers to possess sufficient rigidity to withstand these forces and prevent elastic deformation. Experimental data shows that milling machines equipped with RV reducers achieve drive system rigidity over 40% higher than conventional reducers under heavy cutting conditions.

● Wide Speed Ratio Range

CNC milling machines need to adapt to various operating conditions from finishing to roughing. This requires reducers to maintain stable transmission performance across a wide speed ratio range (typically 1:3 to 1:100).

Case Study: HONPINE Precision Reducers in CNC Milling Applications

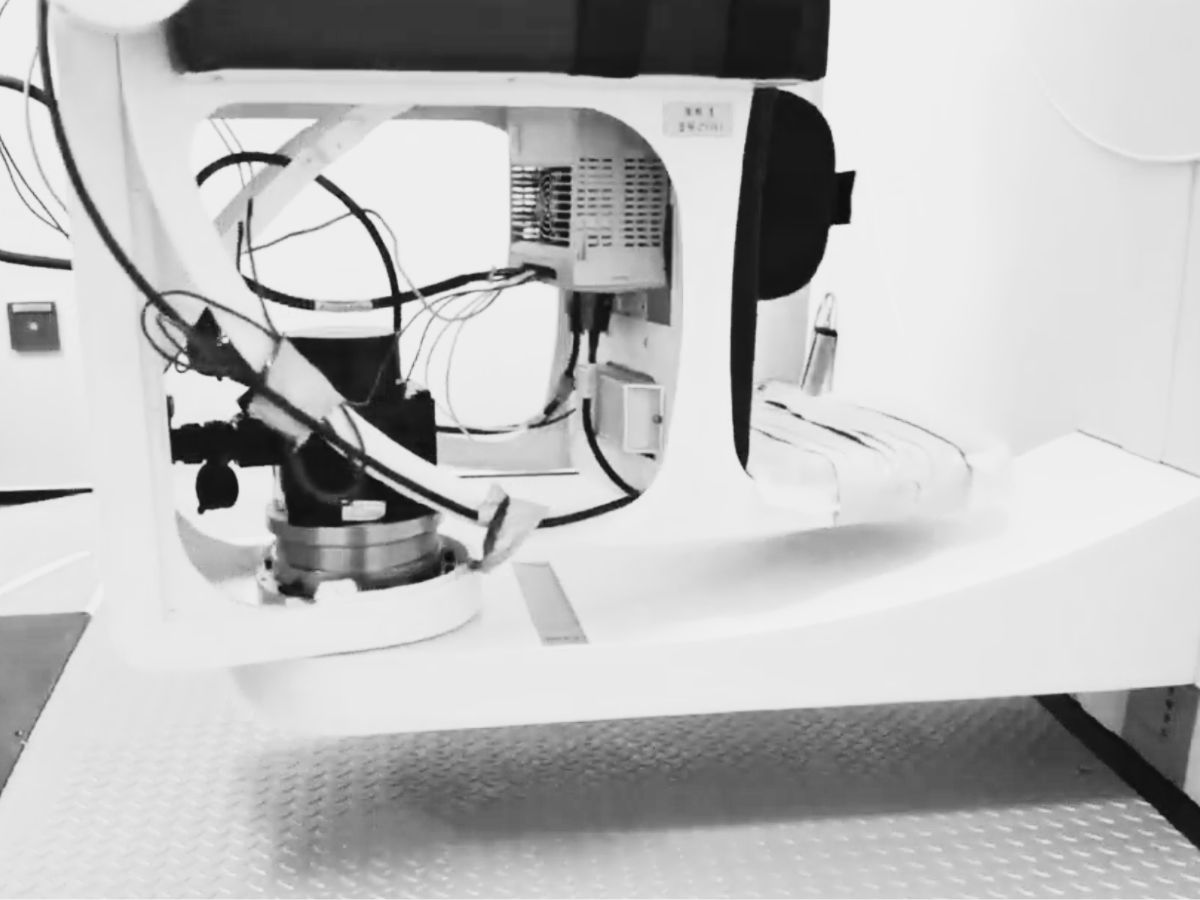

This example demonstrates the application of HONPINE NF series planetary reducers (model NF140, single-section, S1 backlash grade, P1 mounting flange) in CNC planer-type horizontal boring and milling machines. These reducers are primarily used for machining medium-to-large housings, casings, and machine bases, with three units typically installed per machine (X, Y, and Z axes).

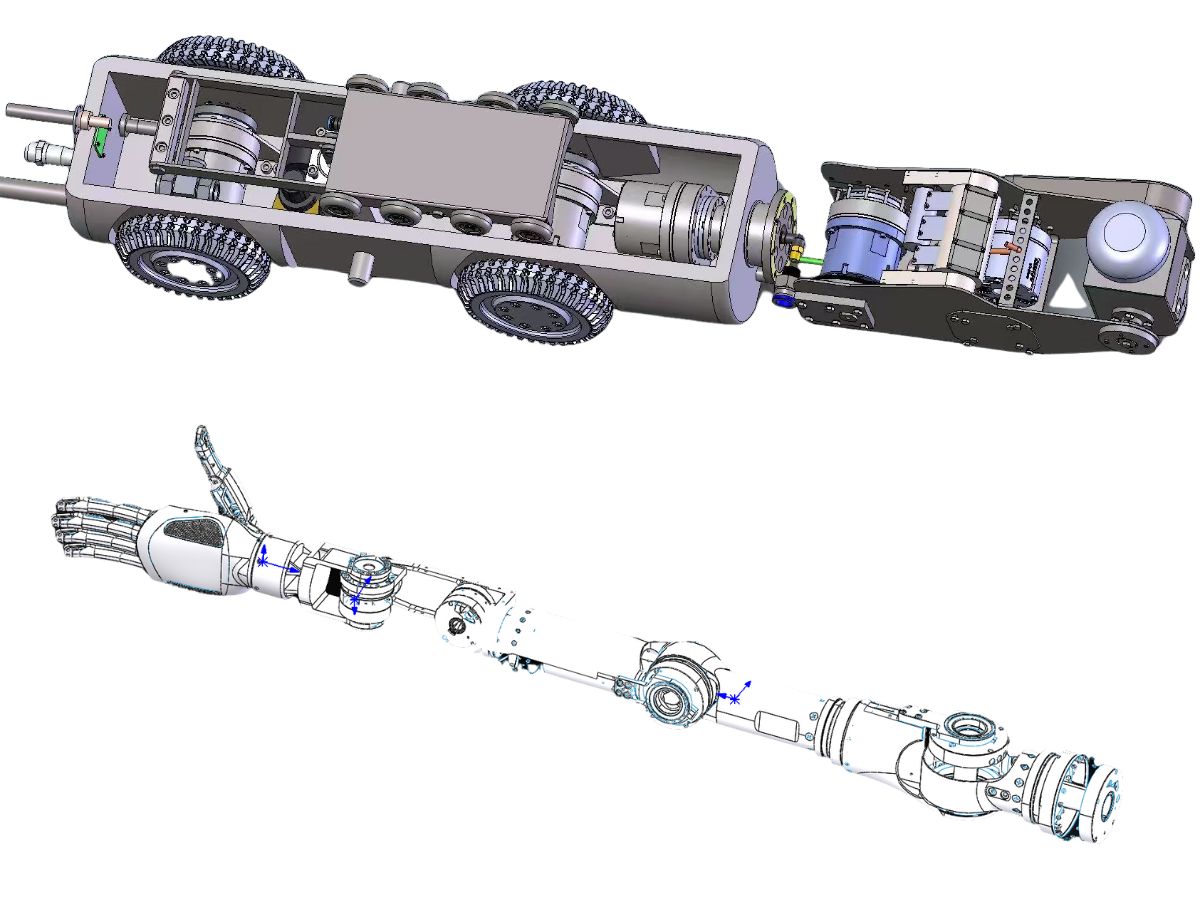

HONPINE harmonic reducers are frequently employed in rotary tables (A/C axes) of high-precision five-axis machining centers due to their advantages in precision and compact design.

Industry Trends and HONPINE's Innovation

With advancements in high-tech fields like microelectronics, optoelectronics, and nanotechnology, requirements for machining micro-components and devices are becoming increasingly stringent. CNC milling machines now demand even higher precision and reduced tolerances for multi-faceted parts machining.

In response, HONPINE has developed its patented anti-backlash planetary reducer. Through rigorous testing in multiple CNC applications, this reducer has demonstrated its ability to revolutionize traditional precision transmissions in machining with its exceptional accuracy and high torque capacity.

Contact HONPINE today to select the optimal precision reducer solution for your specific machine tool requirements.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand