Ultra-Small Harmonic Drive – Precision Manufacturing with High-End Materials

HONPINE’s SHD and CSF series of ultra-small harmonic drives mark a breakthrough in compact harmonic drive technology. Comparable in size to a paperclip, these drives are available in four models (03, 05, 08, and 11), each offering multiple input/output configurations (shaft and flange) and gear ratios (30, 50, 80, and 100) to meet diverse torque and speed requirements—resulting in dozens of product variations.

How HONPINE Overcame Production Challenges in Ultra-Small Harmonic Drives

1. Breakthrough in Micro Flex Spline Bearing Technology

Conventional multi-stage machining is unsuitable for micro flexible bearings due to their thin, small-diameter design, which introduces dimensional errors and deformation risks. Instead, HONPINE developed a single-setup composite machining process in collaboration with a leading bearing research institute. By integrating grinding and laser heat treatment into precision machining centers, the company achieved a streamlined workflow—turning, heat treatment, grinding, and superfinishing—all completed in one operation, ensuring high precision and efficiency.

2. Innovation in Ultra-Micro Crossed Roller Bearings

Standard manufacturing methods were inadequate for ultra-small crossed roller bearings. HONPINE’s embedded split-raceway design eliminated the need for specialized micro-grinding equipment, solving the challenge of machining ultra-fine raceways through structural innovation.

3. Advanced Material Science & Heat Treatment

Years of R&D enabled HONPINE to optimize the hardness-toughness balance critical for fatigue resistance in harmonic drives. By analyzing stress accumulation (post-machining) and dissipation (pre-machining), the company developed a proprietary heat treatment process now used in mass production.

4. Proprietary Manufacturing Techniques

Post-Deformation Finishing: A novel method for flex spline tooth machining ensures uniform contact, eliminating inconsistencies in traditional steel flex splines.

S-Shaped Tooth Profile Design: Combining kinematics, tribology, and lubrication science, HONPINE created simulation software to generate optimized S-curves, improving load distribution, reducing friction, and extending lifespan.

Performance & Applications

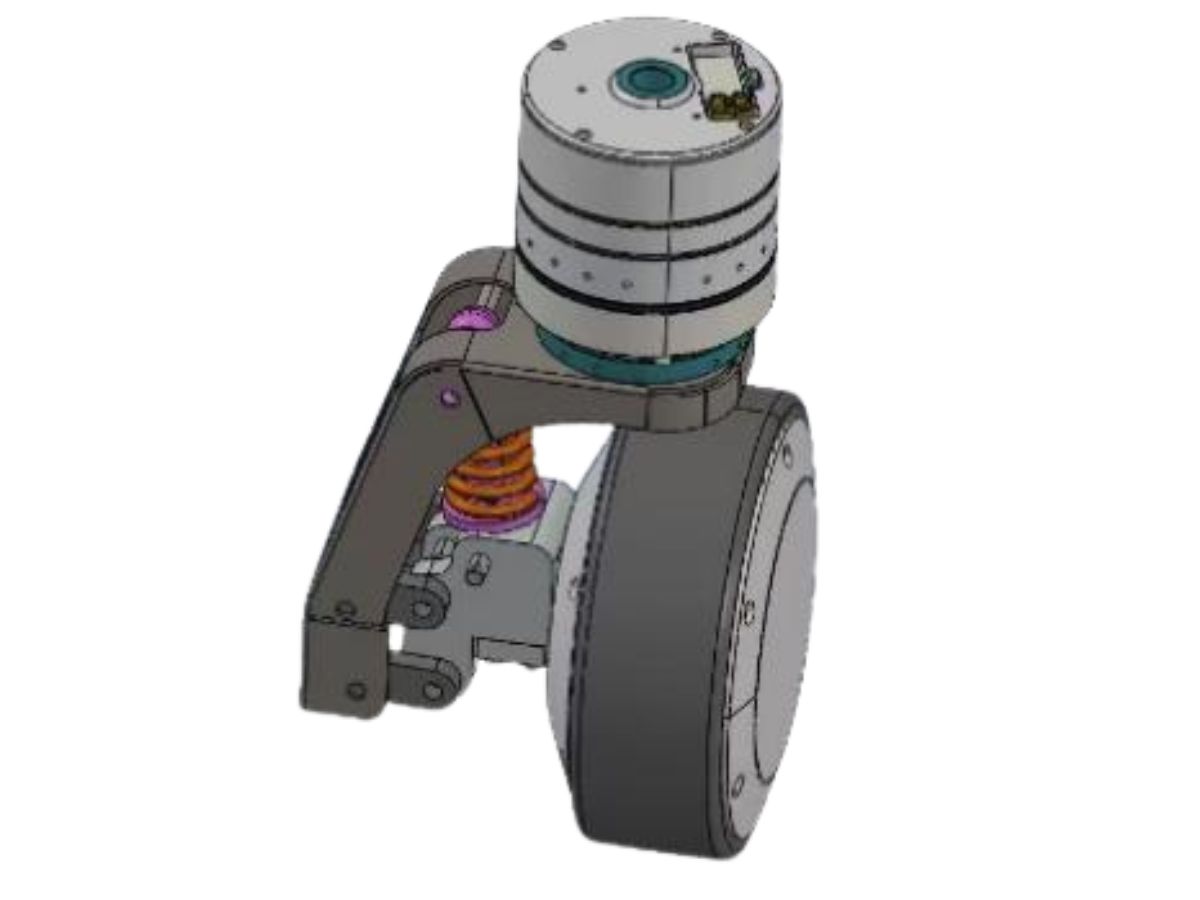

HONPINE’s ultra-small harmonic drives leverage high-end materials and precision engineering for unmatched durability and efficiency. Their low-maintenance, high-performance design makes them ideal for:

Medical & Healthtech (surgical robots, diagnostics)

Service & Light Industrial Automation (AGVs, precision actuators)

Humanoid Robotics (e.g., mechanical finger joints, where the CSF series excels).

With growing demand for compact, high-torque solutions, HONPINE’s drives are setting new standards in miniaturized motion control.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand