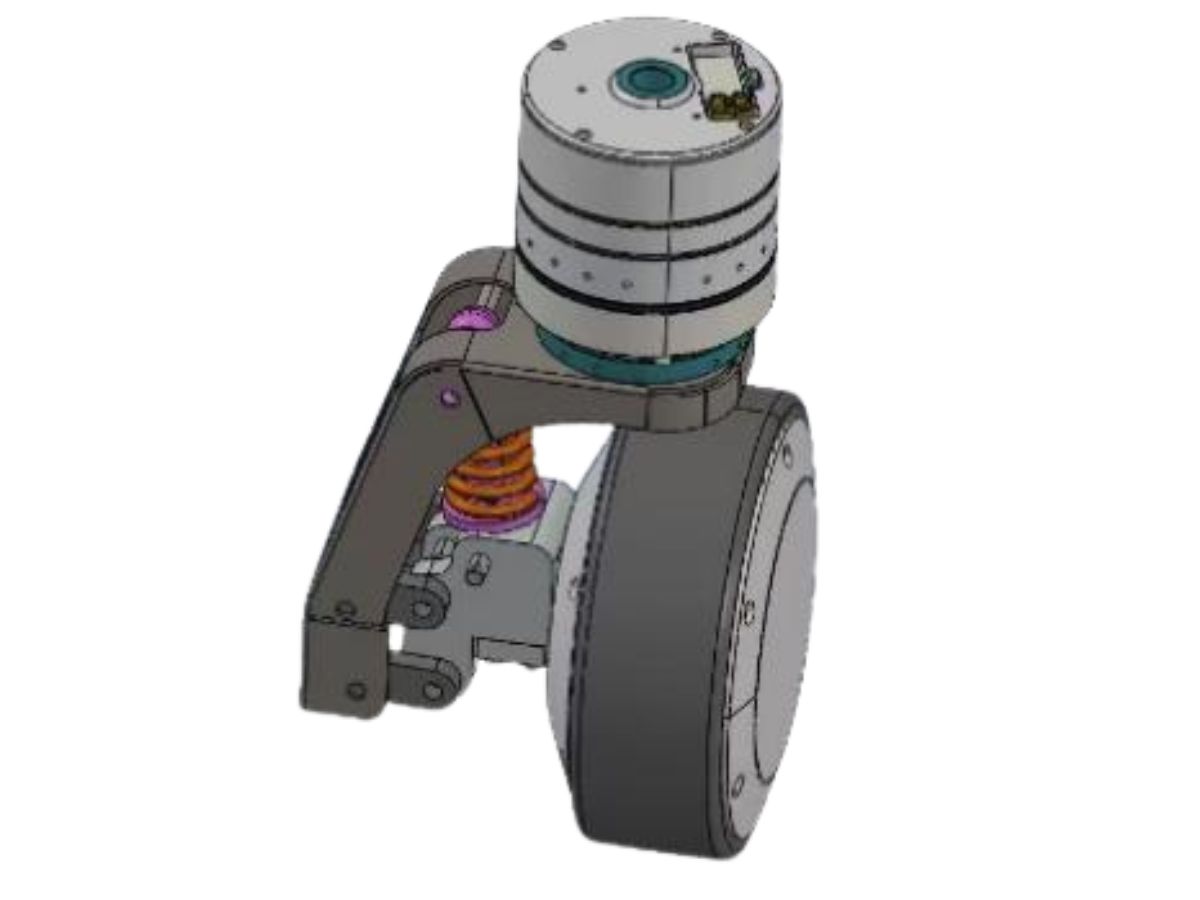

Robot Joint Module Parameter Power-Off Saving Operation Guide

In the daily use of robot joint modules, the stable preservation of parameters is the key factor to ensure the continuous and efficient operation of the equipment. For robot joint modules, mastering the correct parameter power-off saving method can effectively avoid data loss caused by accidental power failure.

When setting parameters for robot joint modules through EtherCAT communication, special attention should be paid: all parameters are in volatile memory by default after writing. This means that if a special power-off saving operation is not performed, once the device is powered off, the previously set parameters may be lost, affecting the normal operation of the robot.

If you need to save parameters during power-off, follow the steps below: write value 1 to parameter 0x2000 through SDO, and then verify by reading the parameter again. When the read value becomes 0, it means that the parameter has been successfully saved during power-off. This interactive process is the core operation to ensure stable storage of parameters, which can keep the parameters intact after power failure.

In addition, there are two important precautions to keep in mind: First, the power-off saving operation of parameters cannot be performed when the motor is in Servo ON state. Therefore, before operation, it is necessary to confirm that the motor is in Safe-Torque Off (STO) state; secondly, when the device is in an error state, parameter saving cannot be completed. At this time, the error condition should be resolved first, and then the saving operation can be performed after the device returns to normal.

Correctly mastering the power-off saving method of the robot joint module can provide a solid guarantee for the stable operation of the robot, reduce the downtime caused by parameter problems, and improve the efficiency of equipment use.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand