Why Choose a Harmonic Servo Rotary Actuator as the Drive System for a Five-Axis Rotary Table?

The core requirement of a five-axis rotary table is to achieve continuous and smooth cutting of complex spatial surfaces. This demands that the rotary table not only withstand cutting forces but also exhibit extremely high rigidity and absolute zero backlash. The Harmonic Servo Rotary Actuator fundamentally eliminates issues such as backlash, wear, and elastic deformation inherent in worm gear systems, making it the optimal choice for high-end five-axis rotary tables.

Worm Gear vs. DD Motor vs. Harmonic Servo Rotary Actuator

Five-axis rotary tables can use worm gears, DD (Direct Drive) motors, or rotary actuators as drive systems. So, what are the differences?

Worm Gear

Worm gears are simple in structure and low in cost, with self-locking capability. However, their accuracy degrades over prolonged use. They are suitable for low-end, economical five-axis machine tools.

DD Motor

DD motors have no gear transmission, achieving zero backlash and high accuracy. However, for the same size, they offer low torque density, poor servo rigidity, and high installation and maintenance costs. They are suitable for OEMs with strong in-house R&D and integration capabilities, requiring significant resources to address integration issues.

Harmonic Servo Rotary Actuator

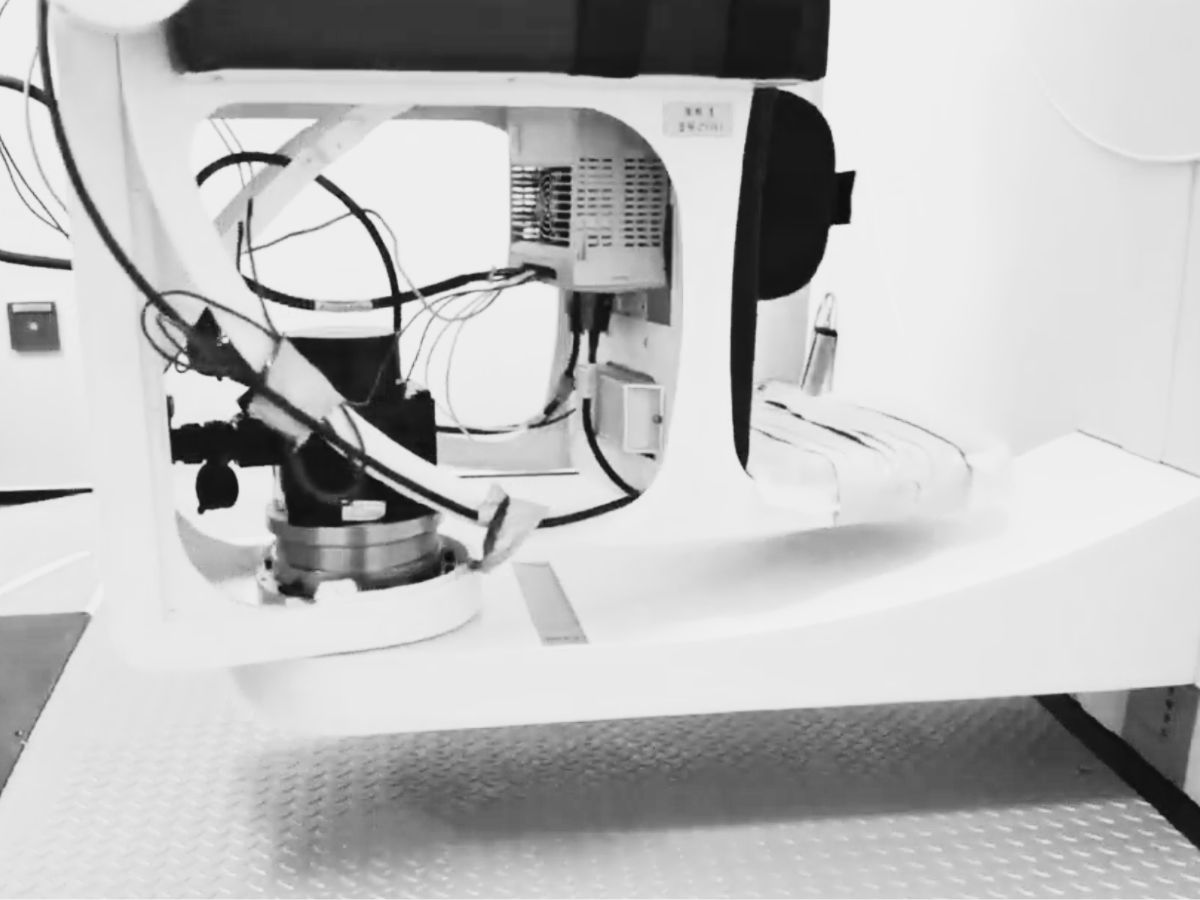

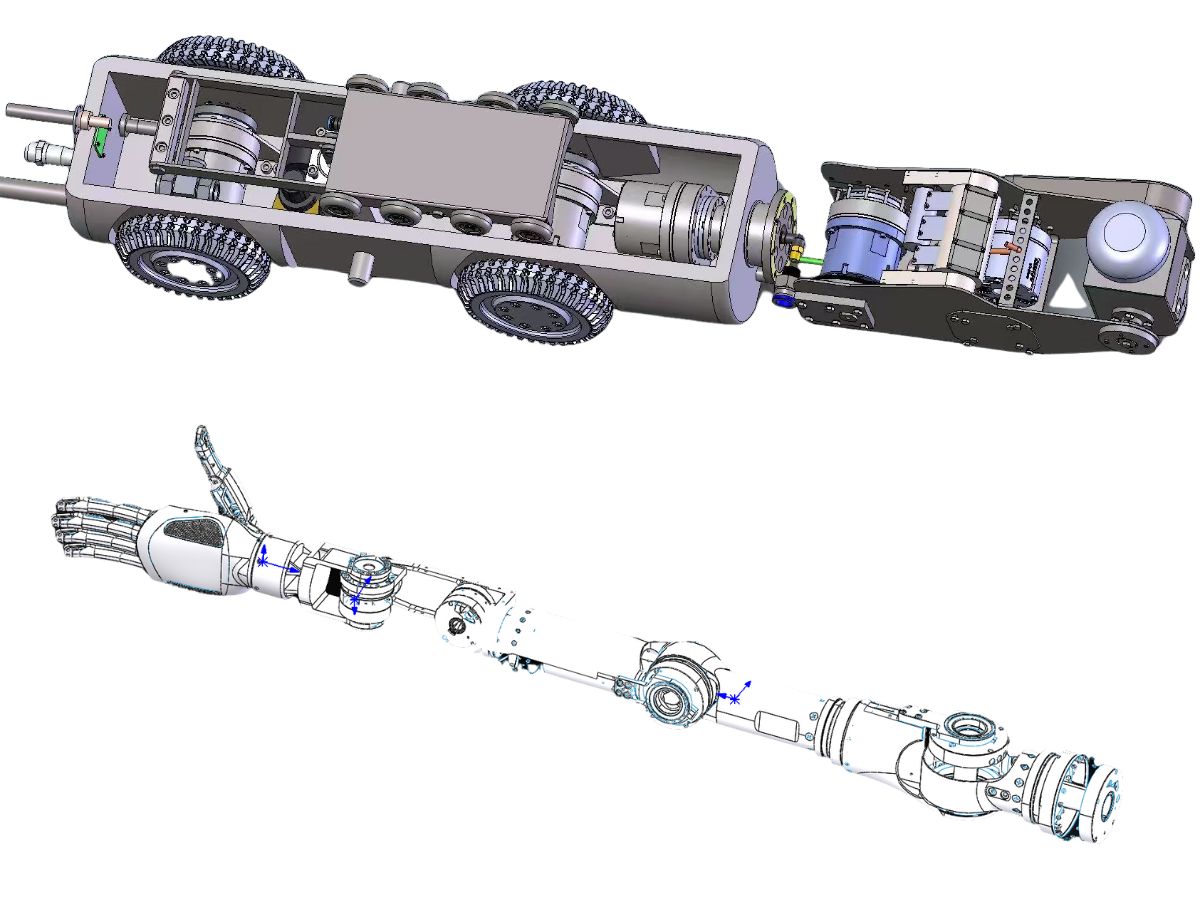

Harmonic Servo Rotary Actuators are typically used for the A and C axes of five-axis rotary tables (which consist of three linear axes and two rotary axes). They offer high precision, long service life, and low noise. They are the best choice for high-end five-axis machine tools, providing the most reliable solution when considering precision, rigidity, and speed comprehensively.

Why Choose HONPINE Harmonic Servo Rotary Actuator?

HONPINE Harmonic Servo Rotary Actuators achieve repeat positioning accuracy within 10 arc seconds. Featuring a modular design and continuous optimization of tolerance matching and dimensional chains, they ensure high rotational accuracy whether assembled in cold or thermally balanced states. This fundamentally resolves compatibility issues between different hardware components and reduces maintenance costs.

Modern five-axis rotary tables often involve small-segment, high-frequency interpolation motions, requiring extremely fast acceleration/deceleration capabilities and high dynamic response. The Harmonic Servo Rotary Actuator is the ideal drive solution and offers exceptional cost-effectiveness from a long-term perspective.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand