Harmonic Drive Reducer, RV Reducer Gearbox, and Precision Planetary Reducer Help Wafer Handling Systems Achieve Higher Levels of Automation

With the continuous advancement of technology, wafer handling robots are gradually achieving higher levels of automation to meet the demands and challenges of the semiconductor manufacturing industry.

● The harmonic drive reducer, due to its zero-backlash, ultra-high precision (arc-second level), and lightweight characteristics, is commonly used in equipment such as wafer handling arms (Wafer Handler), lithography machines (Lithography), and cleanroom-compatible machinery.

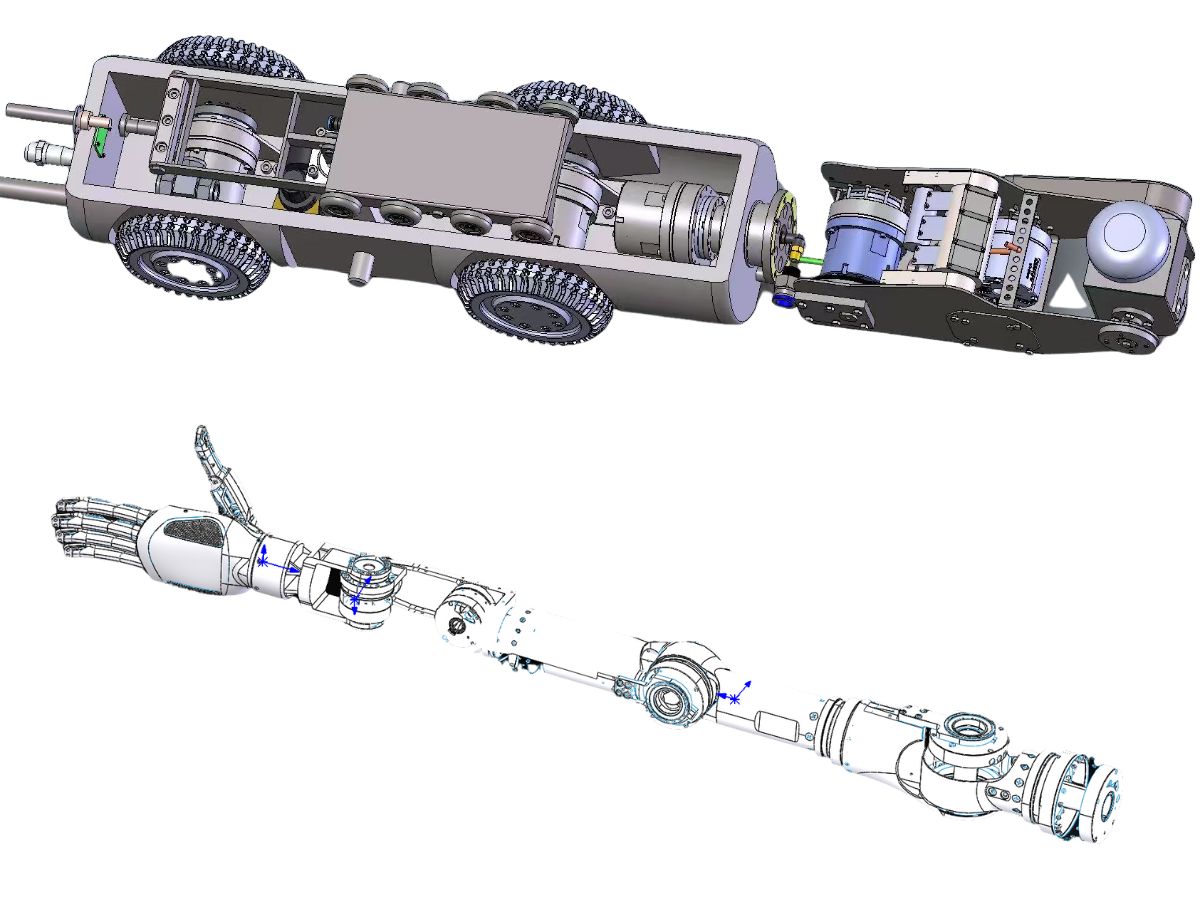

● The RV reducer gearbox, owing to its high rigidity, high torque, and long lifespan, is frequently employed in the base of load-handling robotic arms.

● The precision planetary reducer, with its high torque density and compact structure, is widely used in devices such as wafer conveyor belts, indexing rotary tables, and wafer pre-aligners.

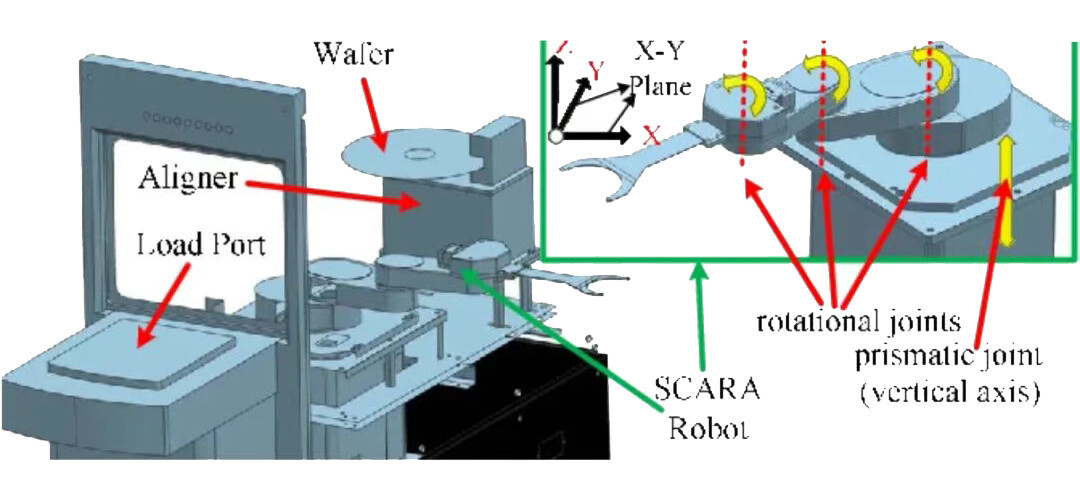

SCARA Wafer Handling Robots Using Direct Drive

SCARA-type robots utilize high-precision angle sensors for position feedback, facilitating robot motion adjustment and rotation angle compensation to ensure the end effector points in any desired direction.

In the J3 and J4 joints (forearm and wrist joints) of SCARA robotic arms, harmonic drive reducers play an irreplaceable role. The elastic flexspline deformation principle of harmonic drives completely eliminates mechanical backlash, which is crucial for ensuring wafer placement accuracy and reducing end-effector inertia.

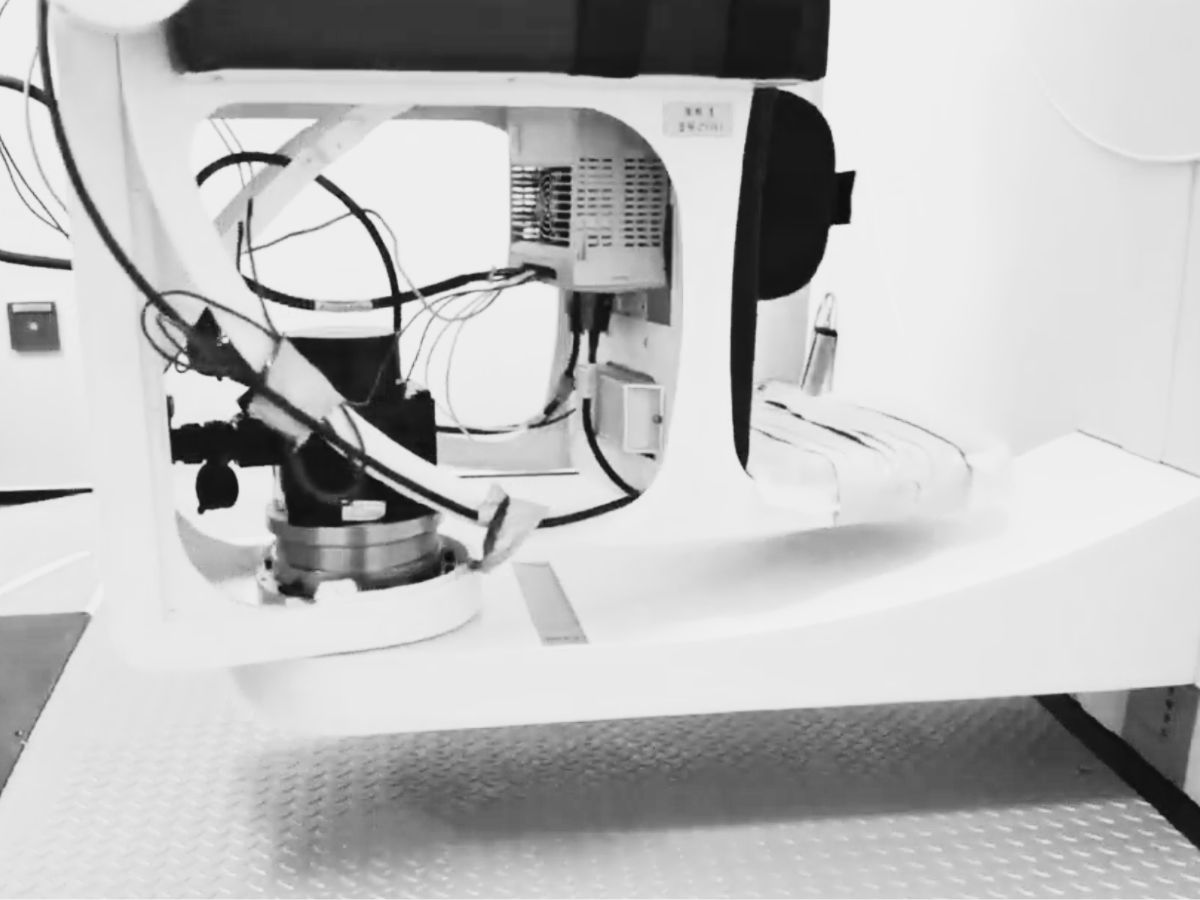

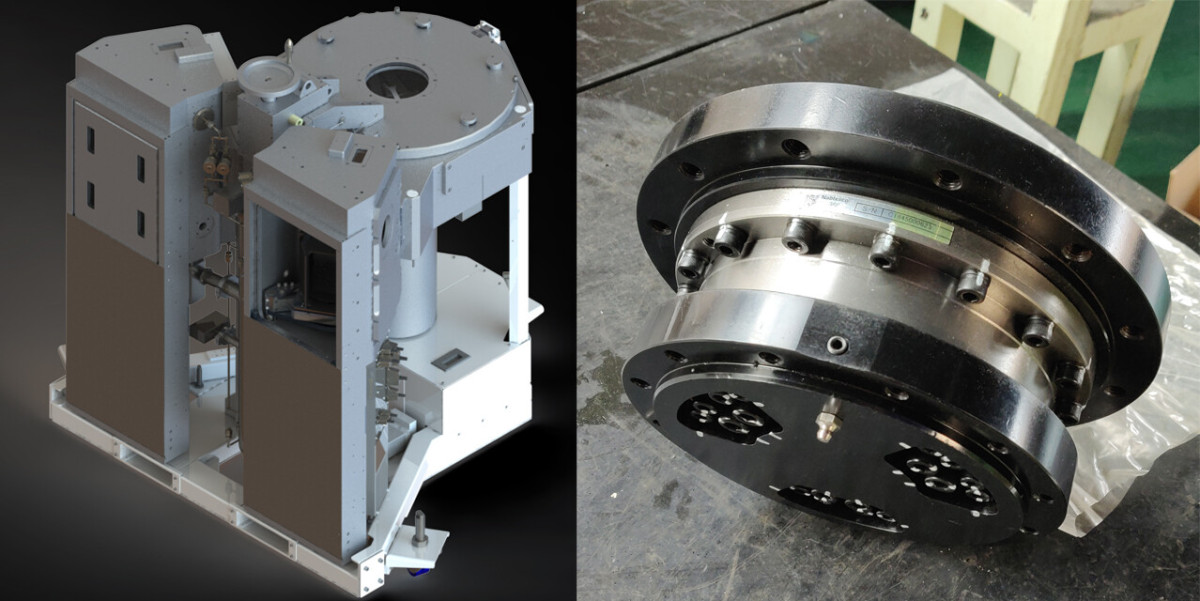

Sealed RV Reducer Gearboxes Assist in Vacuum Wafer Handling Robotic Arms

Due to their high rigidity and long lifespan, RV reducer gearboxes are commonly used components in wafer handling robotic arms. Vacuum wafer handling equipment imposes higher requirements on cleanliness and stability.

HONPINE offers customized sealed RV reducer gearboxes that can integrate built-in motors. The sealed design makes RV reducer gearbox easier to install and use, reducing the installation time for wafer handling systems and improving design safety.

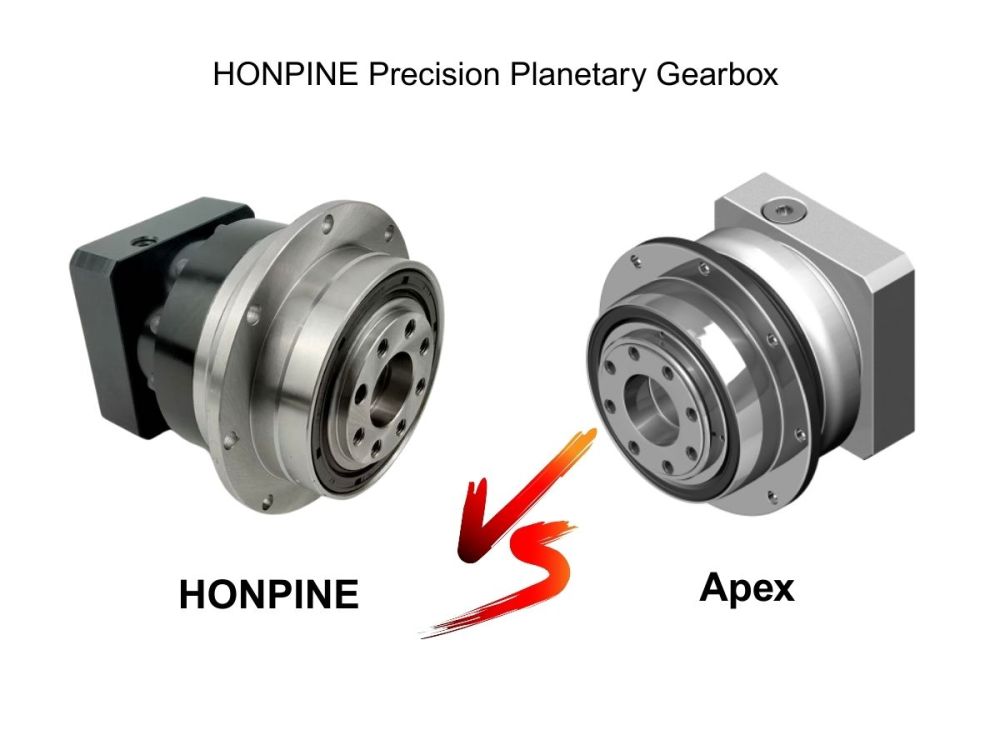

Precision Planetary Reducers Provide Efficient Transmission and Diverse Options

The multi-stage gear arrangement of precision planetary reducers minimizes energy loss, achieving transmission efficiency of over 90%. This high-efficiency energy conversion characteristic helps reduce energy consumption, delivering economic benefits to enterprises.

Wafer handling systems require numerous pieces of equipment, and a single project often involves investments of billions. How to effectively save on initial investment costs and long-term operational expenses is a key consideration for manufacturers.

Additionally, the diverse selection of precision planetary reducers provides enterprises with products that better meet their needs. Depending on the design of the wafer handling system, single-stage, double-stage, or multi-stage reduction configurations can be chosen to match different speed and torque requirements.

Robotic structures come in various forms. For robots with repetitive, fixed trajectories, the appropriate structure and degrees of freedom should be selected based on actual conditions.

Typical rotation solutions for robotic arms include:

Large Arm Rotation: AC servo motor → Harmonic Drive Reducer/RV Reducer Gearbox/Precision Planetary Reducer → Bearing connection → Large arm

Small Arm Rotation: AC servo motor → Harmonic Drive Reducer/RV Reducer Gearbox → Bearing connection → Small arm

When selecting reducers for wafer handling systems, factors such as precision, cleanliness, speed, and load must be comprehensively considered.

Contact HONPINE to work with our technical experts in solving precision transmission challenges for wafer handling systems and receive the most suitable reducer solutions.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand