Harmonic Drive Motor Unlocks Unique Advantages for Cobots

In the wave of intelligent manufacturing, cobots are rapidly emerging as a key force driving industrial transformation. The harmonic drive motor perfectly fits diverse application scenarios for cobots and is widely used in electronics, automotive, medical, and other industries. It helps enterprises improve production efficiency, reduce costs, and enhance product quality.

Harmonic Drive Motor Ensures Safe Operation of Cobots

At the heart of the harmonic drive motor is the harmonic drive reducer, featuring near-zero backlash. This makes cobots more sensitive in force control and collision detection, allowing them to quickly identify abnormal resistance and avoid potential harm to humans.

The HONPINE harmonic drive motor delivers higher torque output within the same volume, making robot joints more compact and lighter. This reduces overall weight, so if a collision occurs, the impact force is smaller—ensuring greater safety.

Equipped with external torque sensors, the harmonic drive motor can detect real-time changes in joint torque. When abnormal torque caused by human contact is detected, it immediately triggers safety mechanisms to stop or adjust movement, preventing injury.

Harmonic Drive Motor Improves the Usability of Cobots

The harmonic drive reducer offers high transmission accuracy, eliminating the need for frequent clearance adjustments or compensation after installation, thereby lowering maintenance costs. By integrating the motor and harmonic reducer into a joint module, users can quickly deploy cobots with simple wiring and parameter settings.

This reduces the learning curve. Even non-specialists can easily operate cobots after minimal training. Unlike traditional industrial robots with complex programming, cobots use graphical interfaces and touchscreen controls, enabling operators to complete task setup and programming through simple clicks and drag-and-drop actions.

Harmonic Drive Motor Enhances the Flexibility of Cobots

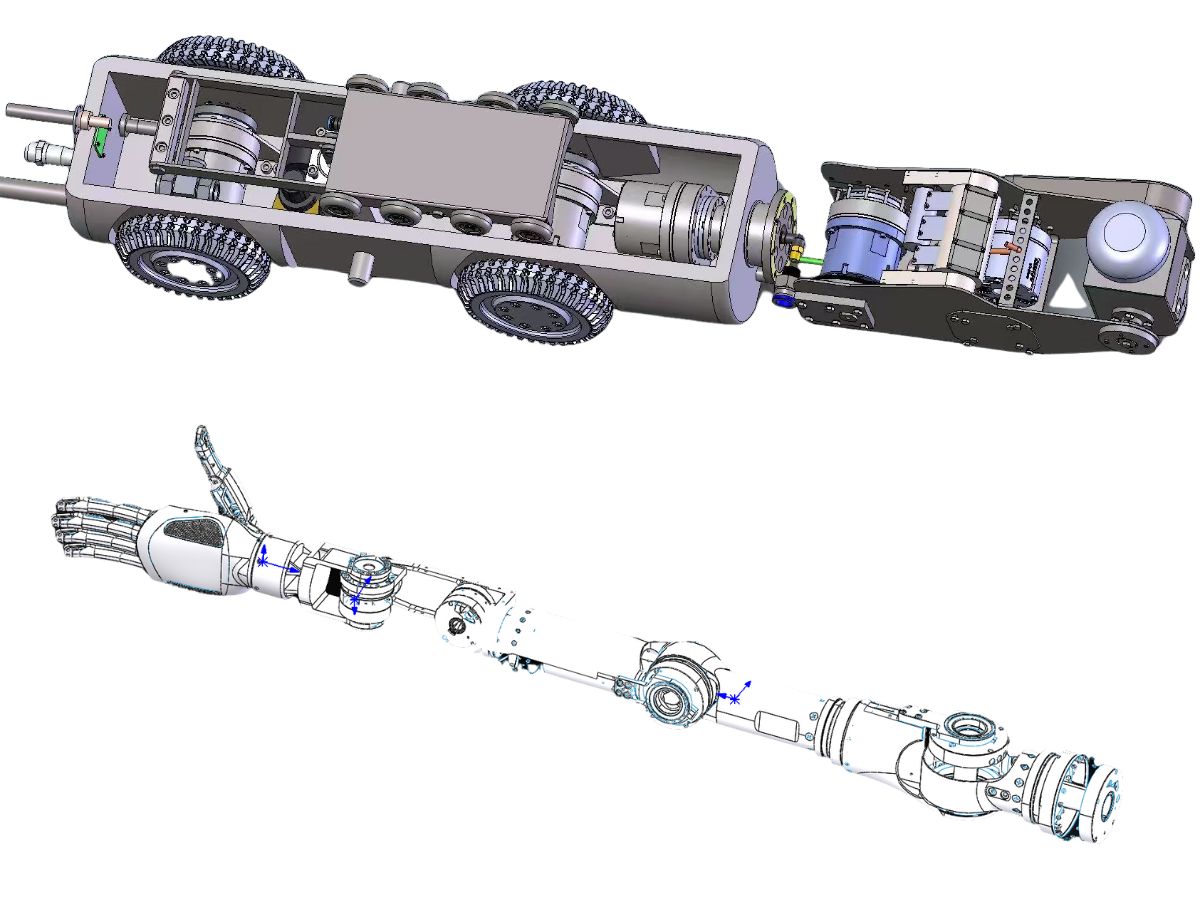

Compact and lightweight, the harmonic drive motor achieves a high reduction ratio in a single stage, enabling small motors to drive complex movements. This increases joint degrees of freedom and overall flexibility.

Cobots are designed with both hardware and software flexibility, quickly adapting to different tasks. Many adopt a modular architecture, allowing joints and components to be flexibly combined and configured—like building blocks—so users can create the optimal robot structure for their needs.

Harmonic Drive Motor Drives Cobots Toward Automation

With high precision and low friction, harmonic drive motors enable fine torque control. The harmonic drive reducer ensures accurate output, and combined with current and torque sensors, allows cobots to respond to environmental changes with smarter decision-making and execution.

As AI and big data technologies continue to advance, cobots are becoming increasingly intelligent and are a crucial step toward smart manufacturing. By integrating AI algorithms, cobots can achieve autonomous learning and decision-making—analyzing large volumes of production data to optimize workflows, improve efficiency, and enhance quality.

As one of the core components of cobots, the harmonic drive motor empowers harmonic reducers to demonstrate unique advantages and broad application value across industries. With ongoing innovation, cobots will see even greater adoption in future industrial automation and smart manufacturing. They will further revolutionize production methods, improve efficiency and quality, create more value for enterprises, and bring more convenience and innovation to everyday life.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand