How Harmonic Joint Modules Empower the Development of Bionic Humanoid Robots

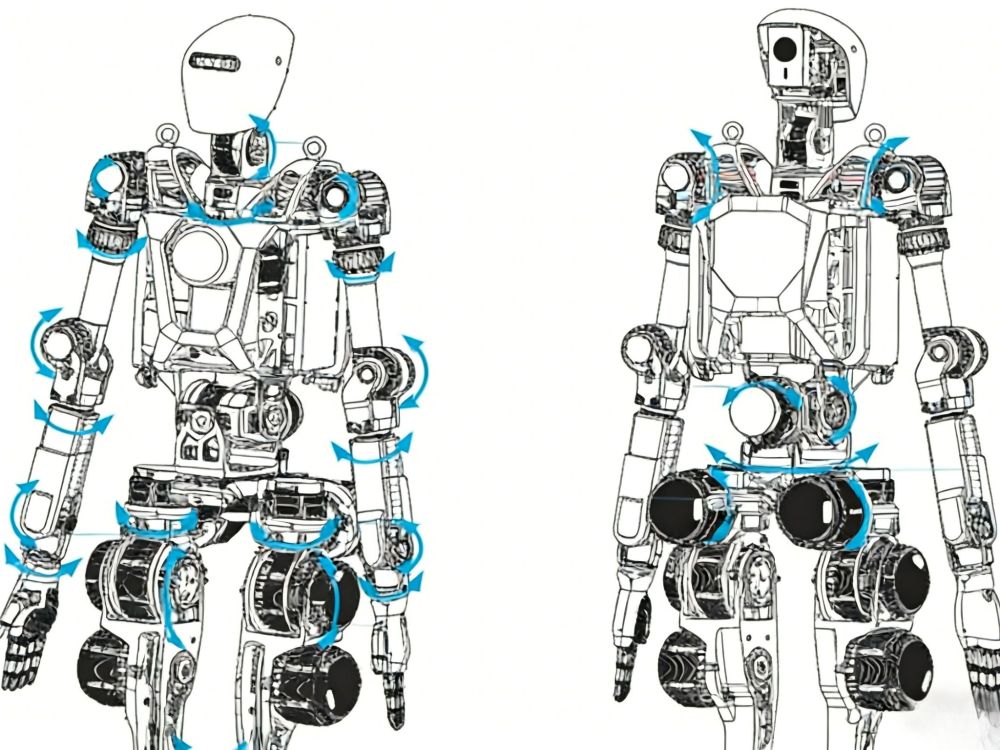

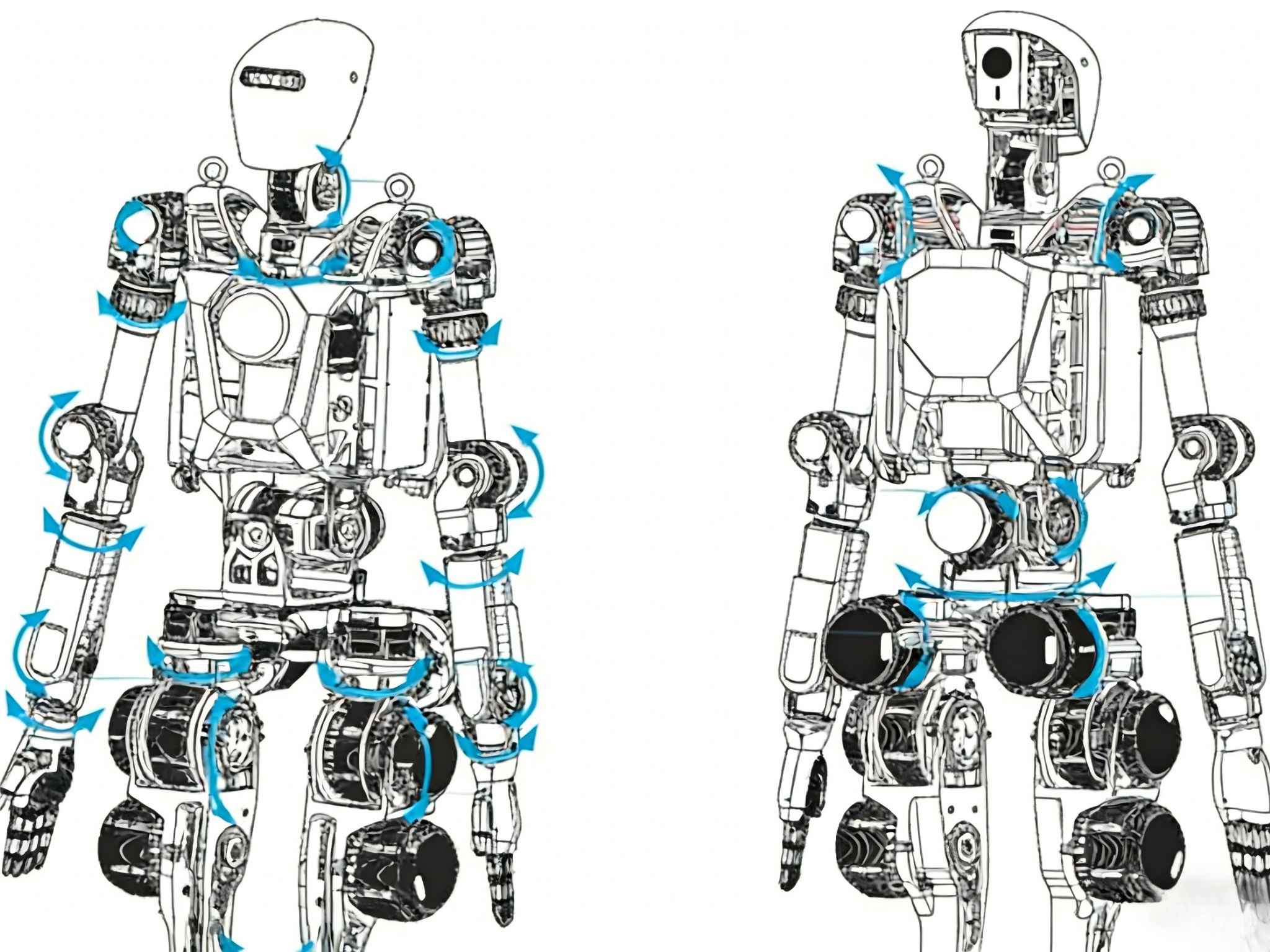

Bionic robots are the driving engine of high-end equipment manufacturing, helping humanity progress from manufacturing intelligence to understanding intelligence.They require high-precision joint modules, intelligent sensing devices, and high-performance control chips and algorithms working synergistically.A typical bionic humanoid robot features 10–40 degrees of freedom. Modular harmonic joint modules simplify system integration, improve reliability, and enhance maintainability.

What is a Bionic Humanoid Robot

A bionic humanoid robot mimics the human form or behavior to replace humans in hazardous or repetitive tasks.They can perform industrial operations such as handling, assembly, and other high-precision actions, as well as provide services in home environments—dancing, opening doors, handing objects, and more—bringing convenience and assistance to daily life.

Why Joint Modules Are Especially Important for Bionic Humanoid Robots

As humanoid robots evolve and adapt to increasingly diverse environments, they must achieve both high-precision control and handle high-load conditions.The robot’s movement capabilities—such as walking, running, or carrying heavy objects—depend entirely on the motor modules distributed throughout its body.These modules are not just simple motors; they are highly integrated power execution units, combining multiple functions for precise and powerful actuation.

Requirements of Joint Modules for Bionic Humanoid Robot

Bionic robots often perform delicate operations such as hand grasping, gait balancing, and posture control.They must move as flexibly, coordinately, and safely as living organisms.Thus, their joint modules must feature high torque density, compact size, and lightweight design, capable of delivering high torque and power within minimal space and mass.

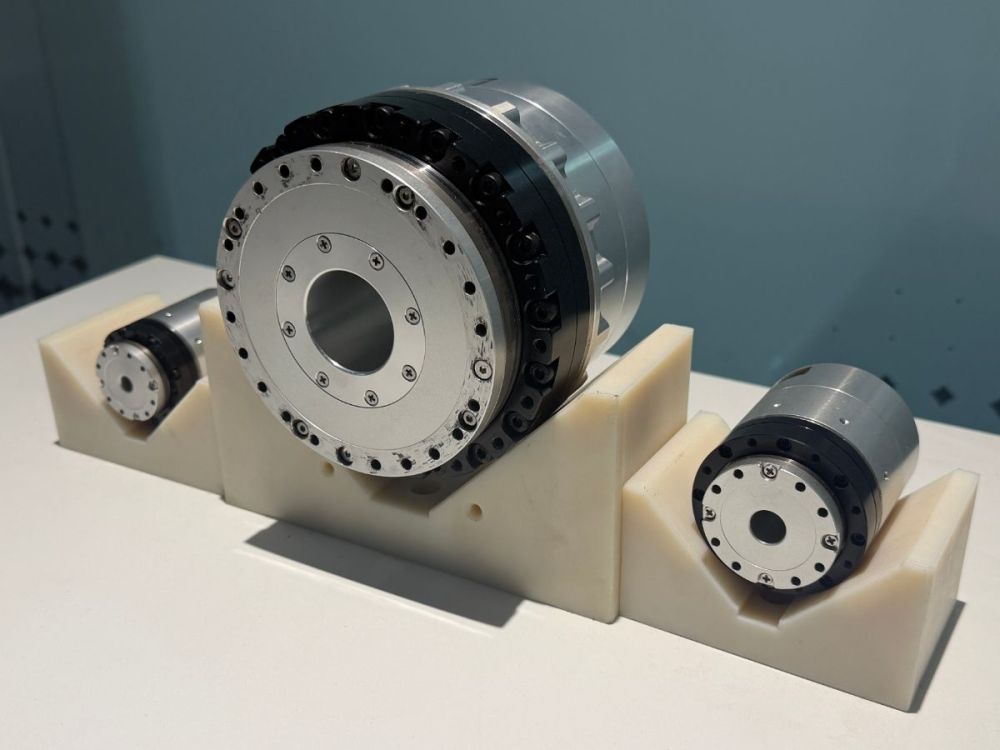

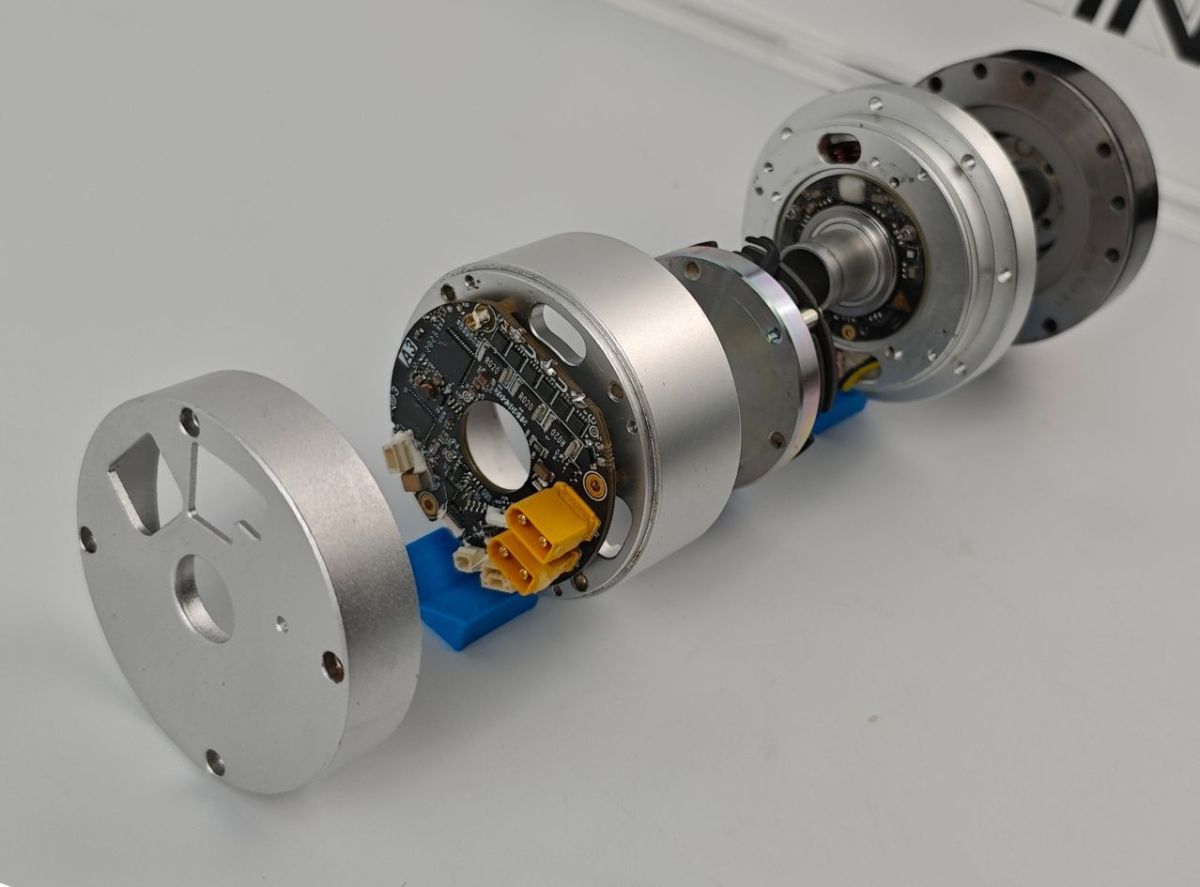

What is a Joint Module

A joint module is a fully integrated unit that pre-packages a motor, reducer, and sensors into one tested and calibrated module.Its internal components are optimally matched, avoiding issues like misalignment and assembly errors that might arise from user installation.This design greatly simplifies R&D and manufacturing.Bionic robot manufacturers can directly purchase and use harmonic joint modules, significantly reducing development cycles and production complexity.

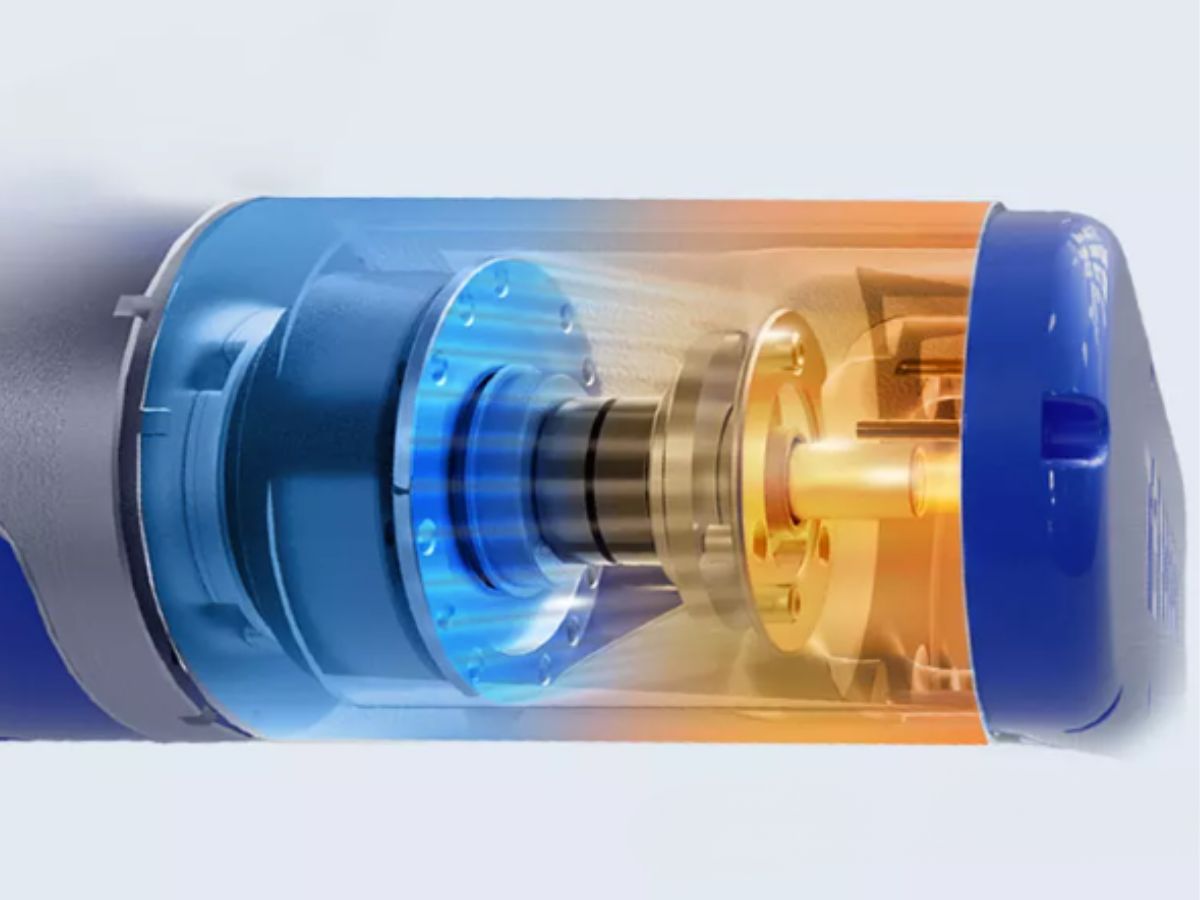

The Roles of the Harmonic Reducer and Frameless Torque Motor

Harmonic Reducer

Due to its multi-tooth engagement design (large contact area), the harmonic reducer can withstand high torque loads.Its structure also provides excellent torsional rigidity—meaning minimal deformation under load, fast system response, accurate positioning, and strong vibration resistance.

This allows robots to perform heavy-load handling or precision machining tasks without noticeable shaking or position deviation.

Frameless Torque Motor

The frameless torque motor’s core concept is direct drive and high integration.

By removing traditional components such as housing, bearings, and output shafts, it provides only the rotor and stator, allowing direct integration into the mechanical structure.

Its compact size, high torque density, and high rigidity make it ideal for joint modules—saving space and weight while enabling slimmer designs and smaller joints.

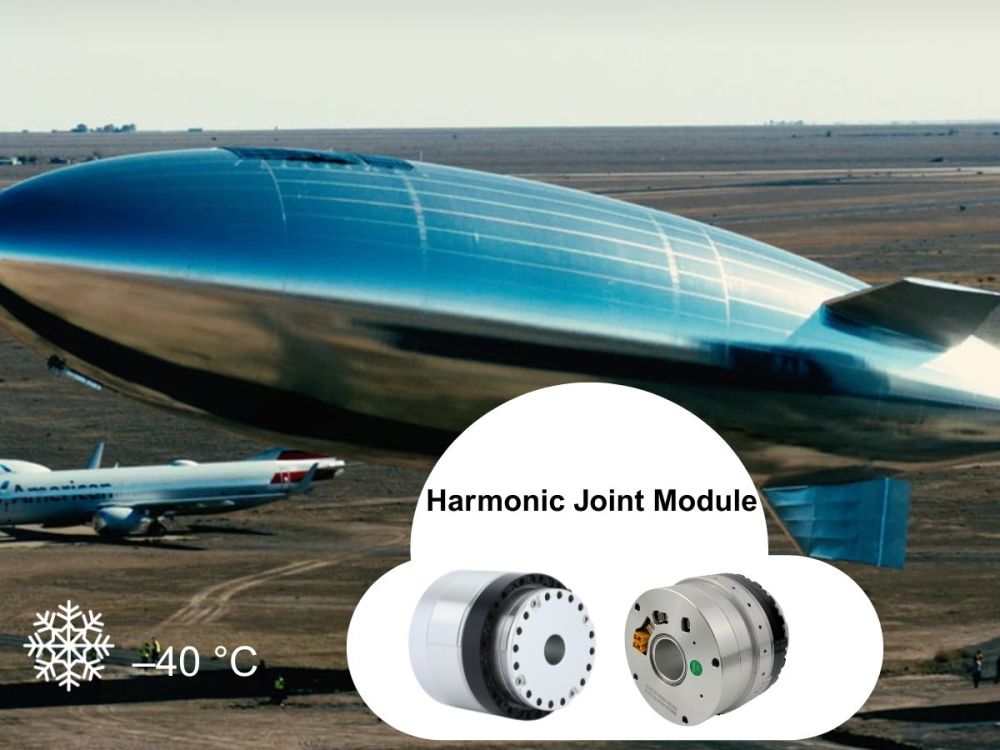

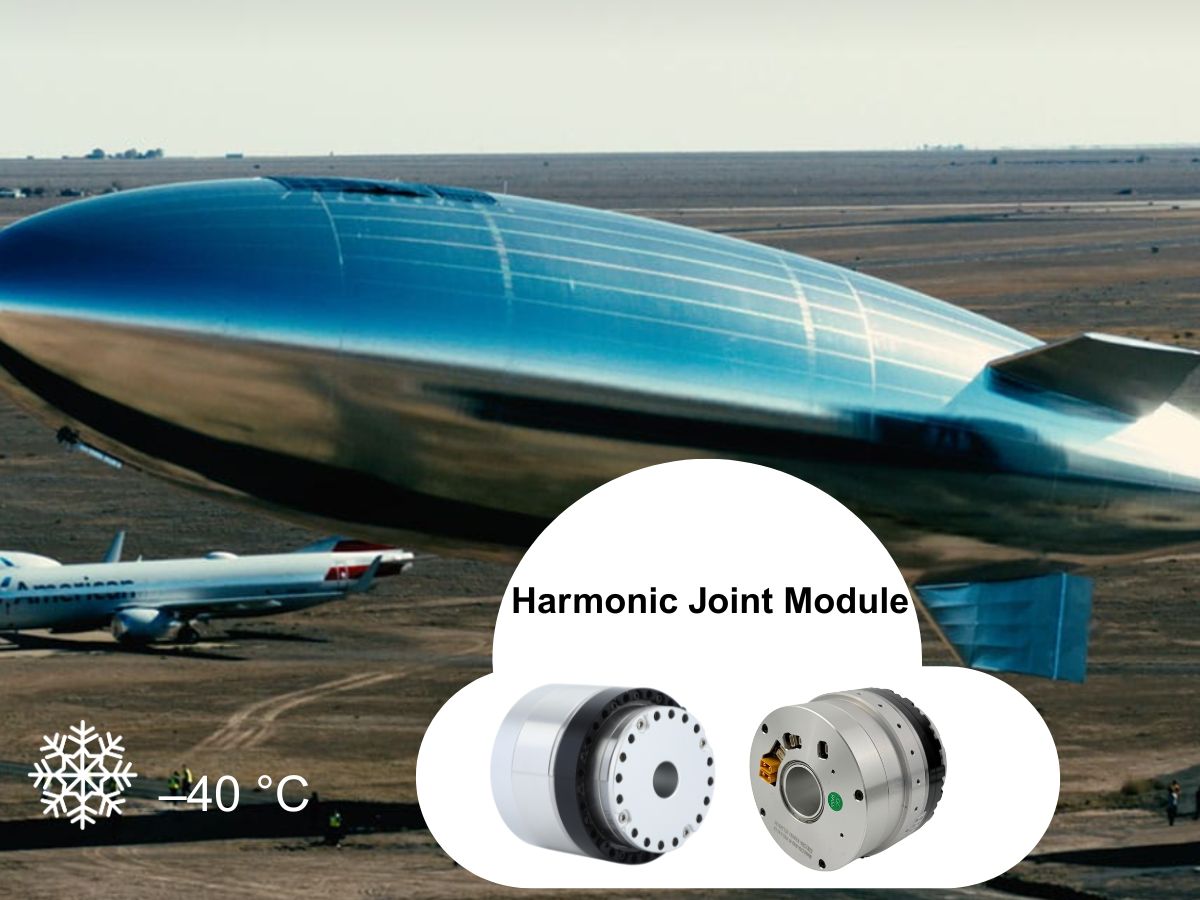

Our New-Generation Harmonic Joint Module

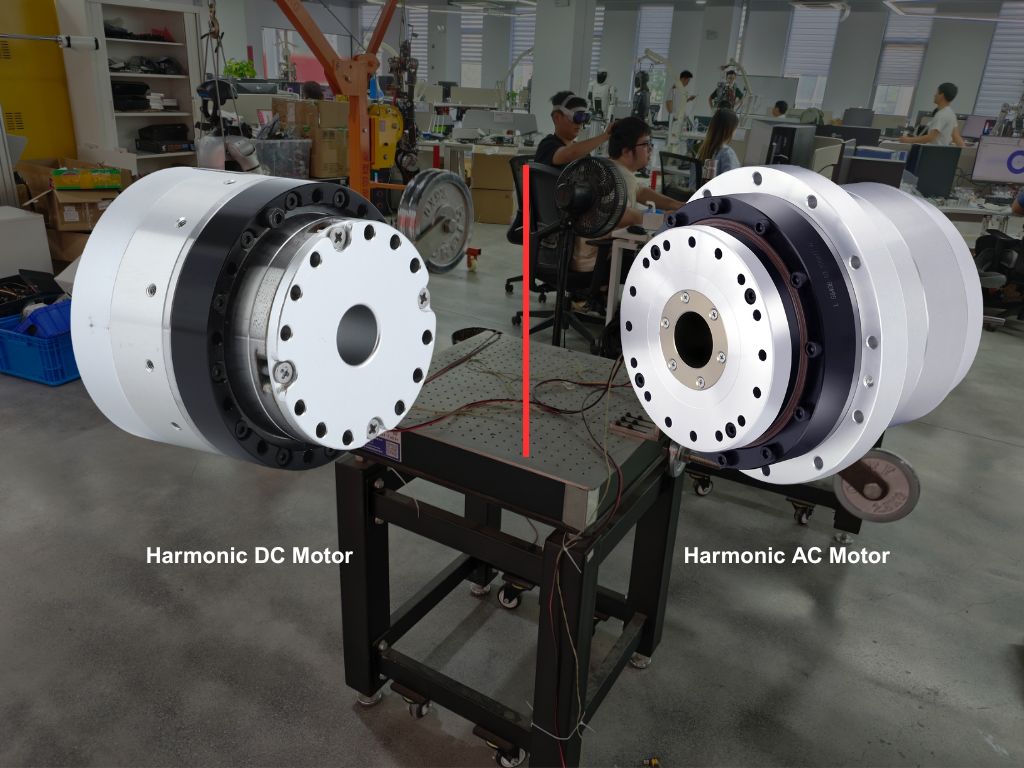

Based on the combination of a frameless torque motor and harmonic reducer, our company has developed a new generation of harmonic joint modules widely used in humanoid robot actuators.

Feature

Extremely high power and torque density

High positioning accuracy and rigidity

Compact and lightweight structure

Higher efficiency and reduced energy loss

For more insights into harmonic joint modules, please refer to the HONPINE News article:

Why the Joint Module is Called the “Power Heart” of the Robot

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand