Why BLDC Harmonic Joint Motors Are the Core Components of Robots?

The Superior Advantages of BLDC Harmonic Joint Motors

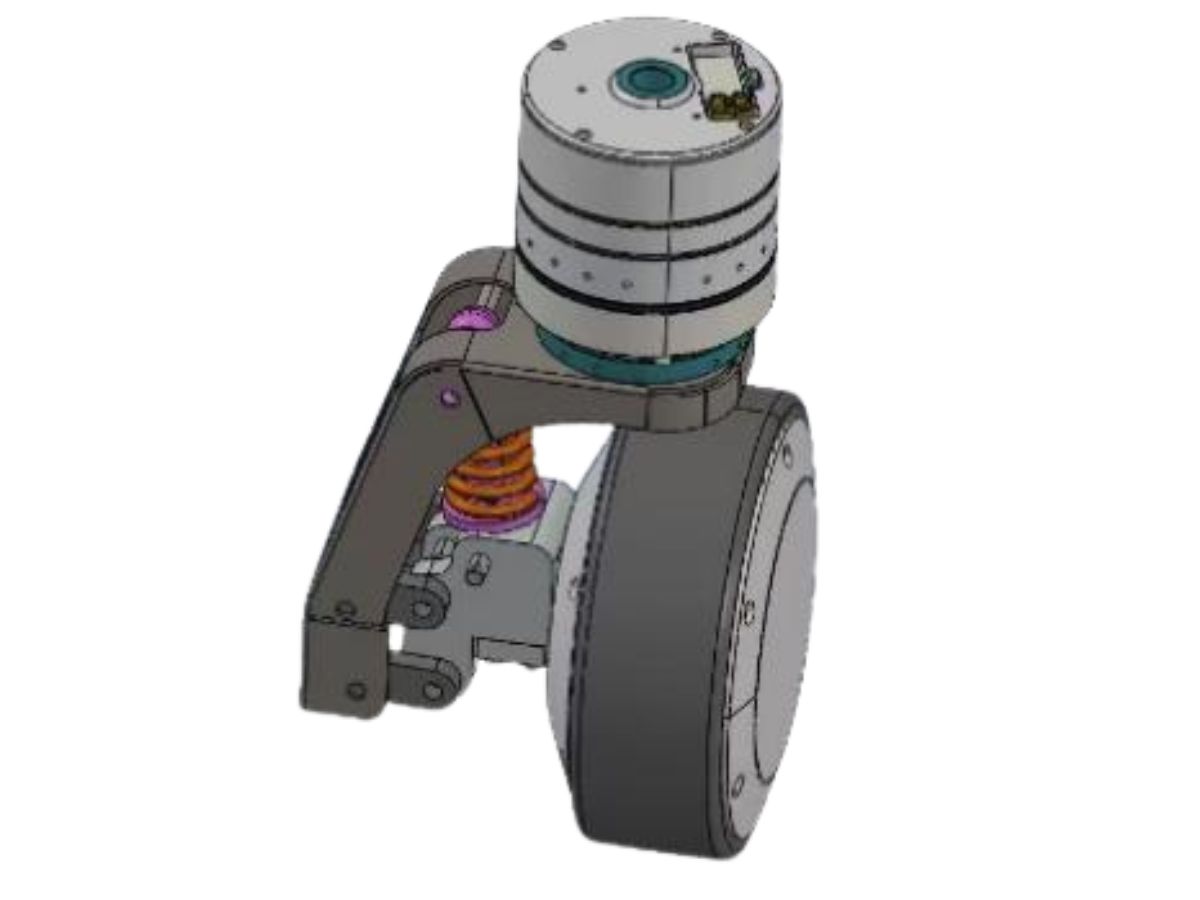

BLDC motors provide a powerful power foundation. Combined with harmonic reducers and encoders, they achieve extremely high position control accuracy and high torque output. BLDC harmonic joint motors feature an industrial-grade design. The long lifespan of brushless motors combined with integrated design enables true plug-and-play operation. Equipped with built-in encoders and torque sensors, they can implement advanced functions such as hybrid force-position control and impedance control, allowing robots to apply force gently and move precisely.

Why BLDC Motors and Harmonic Reducers Are the Best Partners

BLDC motors and harmonic reducers form a perfect partnership. Each demonstrates outstanding advantages in their respective fields, and their combination creates a synergistic effect where 1+1>2. BLDC motors offer extremely high power density (delivering greater power output for the same size and weight), while harmonic reducers provide extremely high torque density (achieving higher reduction ratios and output torque for the same size and weight). Together, they enable precise control of the output torque at the robot's joint.

BLDC Harmonic Joint Motors Have Gained Recognition in Practice

In industrial production, robots can efficiently complete tasks such as part assembly, handling, and welding, significantly improving production efficiency and product quality. In the medical field, they can assist doctors in performing precise surgical operations and reduce surgical risks. Even in home service scenarios, they can help with household chores and care for the elderly and children. The combination of BLDC motors and harmonic reducers can adapt to frequent start-stop operations and highly dynamic working environments in robotics applications, providing long-term stable high-performance output.

Advances in artificial intelligence, sensors, and computer technology have pushed the development of humanoid robots to new heights. BLDC harmonic joint motors serve as the core execution units of humanoid robots, much like joints and muscles in the human body, determining the physical performance limits of humanoid robots.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand