How HONPINE harmonic drive servo motor achieves ultra-high performance and ultra-high precision

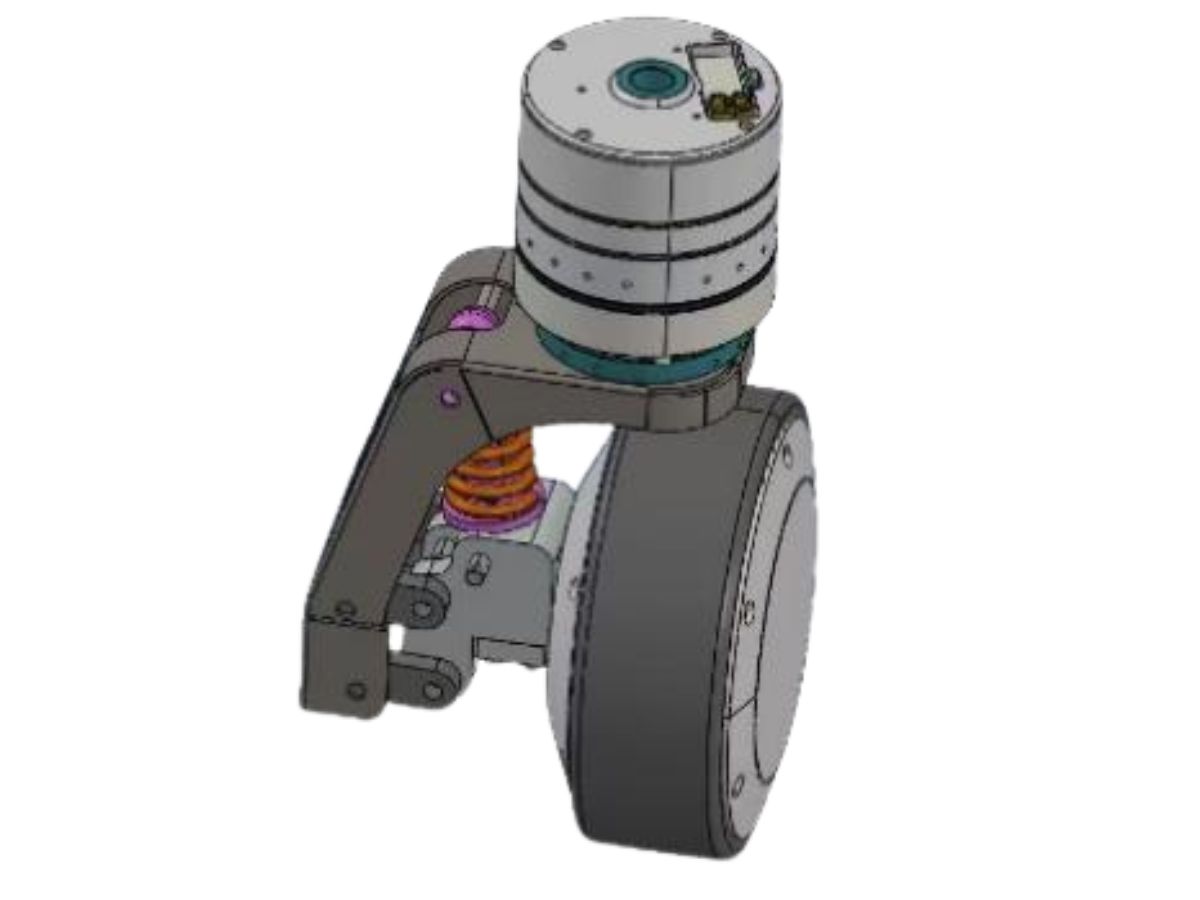

HONPINE harmonic drive servo motorsachieve ultra-high performance and precision through a modular framework that integrates high-precision harmonic drives, high-accuracy optical encoders, and high-power-density motors. Professional testing with laser interferometers ensures stable, accurate, and predictable execution of position commands, meeting the stringent requirements of high-end industrial applications for precise motion.

Design Philosophy of HONPINE Harmonic Drive Servo Motors

The motor section adopts a universal industrial servo design with a dual-bearing support structure, ensuring high rotational accuracy and exceptional stability. The high-power-density motor provides a rated torque that is 1.2 times the maximum average load torque of the reducer. Coupled with a lightweight rotor, it delivers high dynamic response.

For the encoder, we employ high-precision optical absolute multi-turn encoders with optional resolutions of 23-bit or 17-bit.

An electromagnetic brake is available as an option, and wiring can be configured either from the side or the end face.

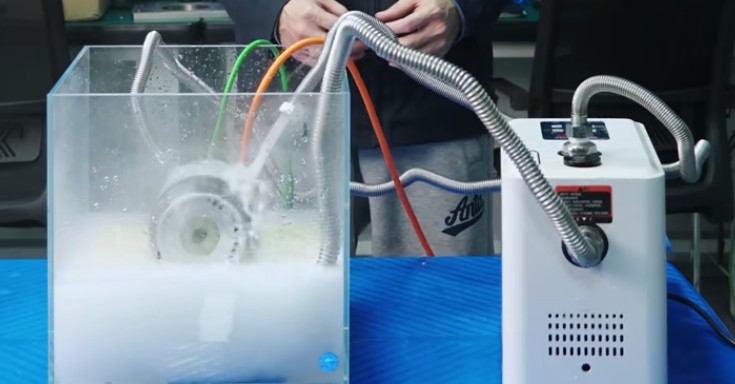

After motor encapsulation, HONPINE conducts individual performance tests. Once testing is complete, the rotary actuator is assembled modularly.

When precision degrades beyond its lifecycle, only the reducer needs replacement, reducing maintenance costs for customers.

HONPINE harmonic drive servo motors feature a fully enclosed design with a protection rating of IP65.

Why HONPINE Harmonic Drive Servo Motors Deliver Ultra-High Precision

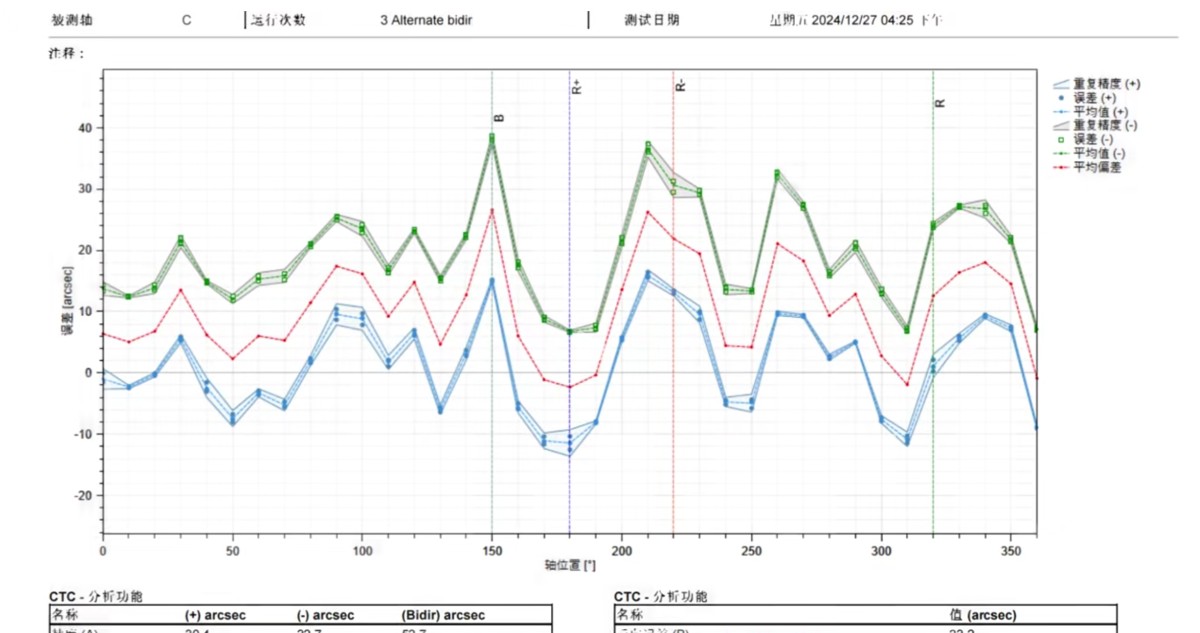

HONPINE harmonic drive servo motors are tested using Renishaw laser interferometers, which include rotary components, laser heads, optical mirrors, and testing software. Through the driver's script program, rotation is controlled—typically sampling one point every 10 degrees, resulting in 36 points for forward rotation and 36 points for reverse rotation, repeated twice. The testing software generates a set of precision curves.

The blue line represents the 0-360 degree accuracy curve, the green line represents the 360-0 degree accuracy curve, and the red line is the average of the blue and green lines. An accuracy of 30.4 arc-seconds indicates the difference between the highest and lowest points of the blue line, while 32.7 arc-seconds refers to the difference for the green line. This value represents positioning accuracy, also known as angular transmission accuracy. For example, theoretically, a 60-degree movement may not be achieved due to backlash error, resulting in an actual movement of only 59.991 degrees.

Ideally, the blue and green lines should perfectly align. The maximum difference at the same angle is defined as repeat positioning accuracy, while the error at the same point between forward 360-degree and reverse 360-degree movements is defined as reverse error.

In daily software debugging, these three values—positioning accuracy, repeat positioning accuracy, and reverse error—most directly impact the transmission accuracy of the rotary actuator. Some systems can compensate for measured data to achieve higher positioning accuracy.

HONPINE harmonic drive servo motors utilize self-developed harmonic drive reducers, with strict selection criteria for motors and encoders. The overall precision and craftsmanship meet high standards, with errors controlled at minimal levels. They are suitable for high-end applications such as medical robotics, 3C automation equipment, semiconductor devices, aerospace, CNC machine tools, laser equipment, and printing and packaging machinery.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand