Breaking Precision Barriers: How HONPINE's Anti-Backlash Planetary Reducer Outperforms Harmonic & RV Reducer

What is an ultra-high precision anti-backlash planetary reducer?

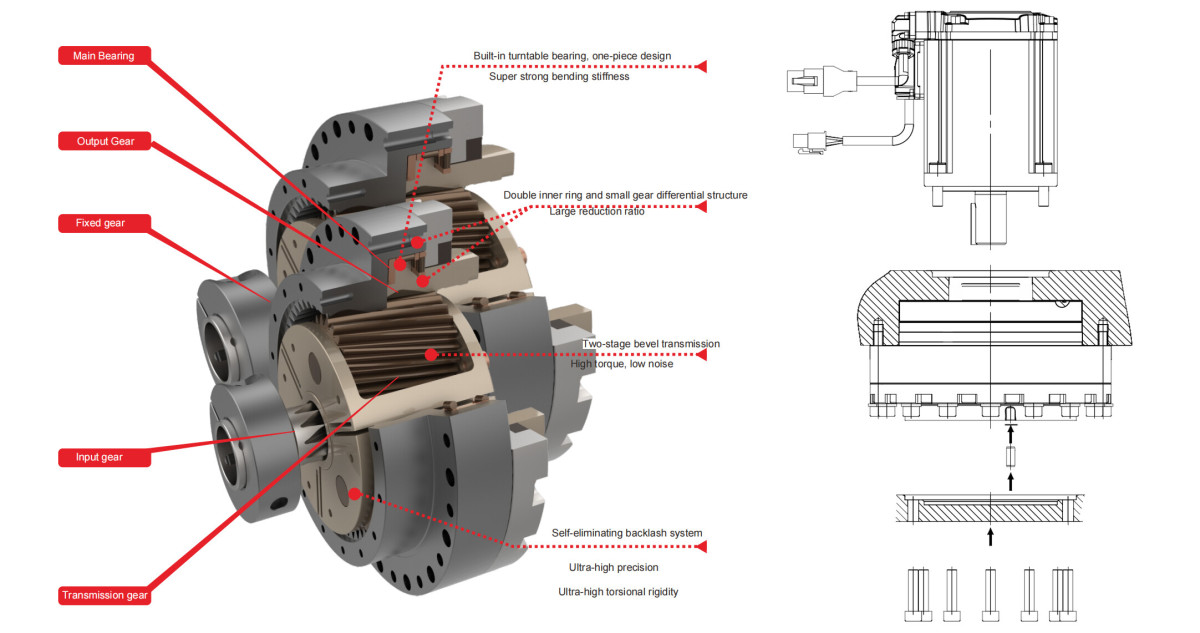

The ultra-high precision anti-backlash planetary reducer has an angle transmission accuracy of up to 7 arc seconds and a positioning accuracy of up to 5 arc seconds, which is much higher than the accuracy level of current harmonic reducers and RV reducers. Its torsional rigidity and main bearing overturning rigidity are much stronger than those of RV reducers, and the service life is longer than that of traditional harmonic reducers. Ultra-high precision anti-backlash planetary reducers give robots and machine tools better performance. They push the accuracy limit of ultra-high rigidity reducers to 15 arc seconds, filling the market gap and making ultra-high precision reducers available for high-end industrial machines.

R&D background of HONPINE ultra-high precision anti-backlash planetary reducer

With the rapid development of Industry 5.0 and intelligent manufacturing, the market demand for precision reducers, as core components of high-end manufacturing equipment, has shown explosive growth. Especially in the fields of robots (industrial robots and humanoid robots), machine tools, aerospace, and medical equipment, precision reducers are being more and more widely used, and the requirements for performance indicators such as precision, rigidity, stability, and lifespan are getting higher and higher.

Traditional harmonic reducers have poor rigidity and a short life. Meanwhile, RV reducers have relatively low precision and low transmission efficiency. To solve these problems, HONPINE established a special R&D team to develop this ultra-high precision anti-backlash planetary reducer, which completely solved the backlash and gear wear problems of precision reducers and raised the precision and rigidity to an unprecedented level.

Application scenarios of ultra-high precision anti-backlash planetary reducers

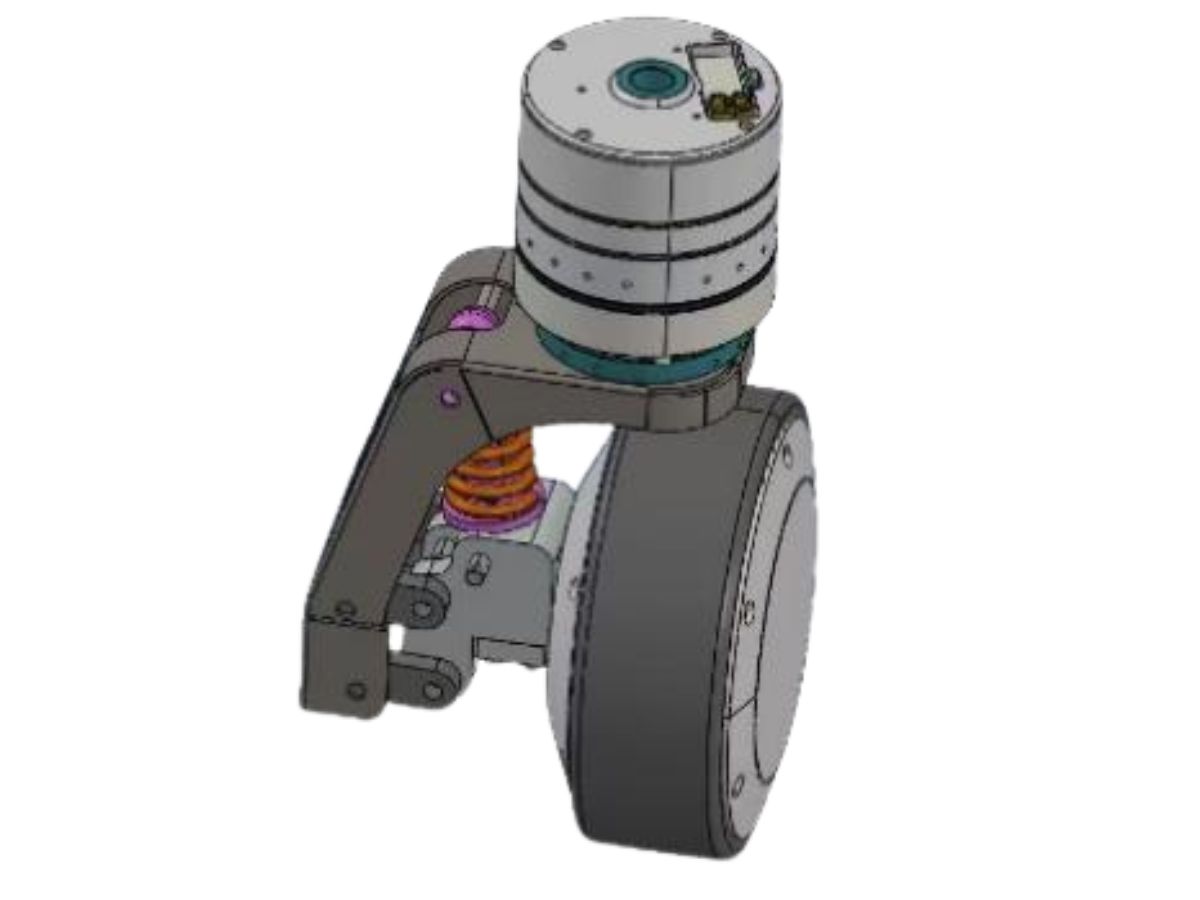

Ultra-high precision anti-backlash planetary reducers are particularly suitable for :Machine tool turntables,Machine tool swing heads,Panel manufacturing equipment,Laser cutting swing heads,Precision measuring equipment,Semiconductor process equipment,FPD process equipment and other applications that require large loads, high precision, and high rigidity. More application areas are being developed and tested.

Hollow shaft series: Features a large hollow aperture design, suitable for applications where a large hollow aperture is required. The speed ratio is 45 or 50.

Solid shaft series: A universal design, suitable for applications where it is directly connected to a servo motor. The speed ratio is 74, 77, or 92.

Why choose HONPINE ultra-high precision anti-backlash planetary reducer?

HONPINE ultra-high precision anti-backlash planetary reducer is HONPINE's new technology, which has raised the precision and rigidity to an unprecedented level. It is a disruptive product upgrade. The current production capacity has reached 100,000 units per year, and a new factory is being planned.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand