Harmonic Drive Transmission Technology Wiki

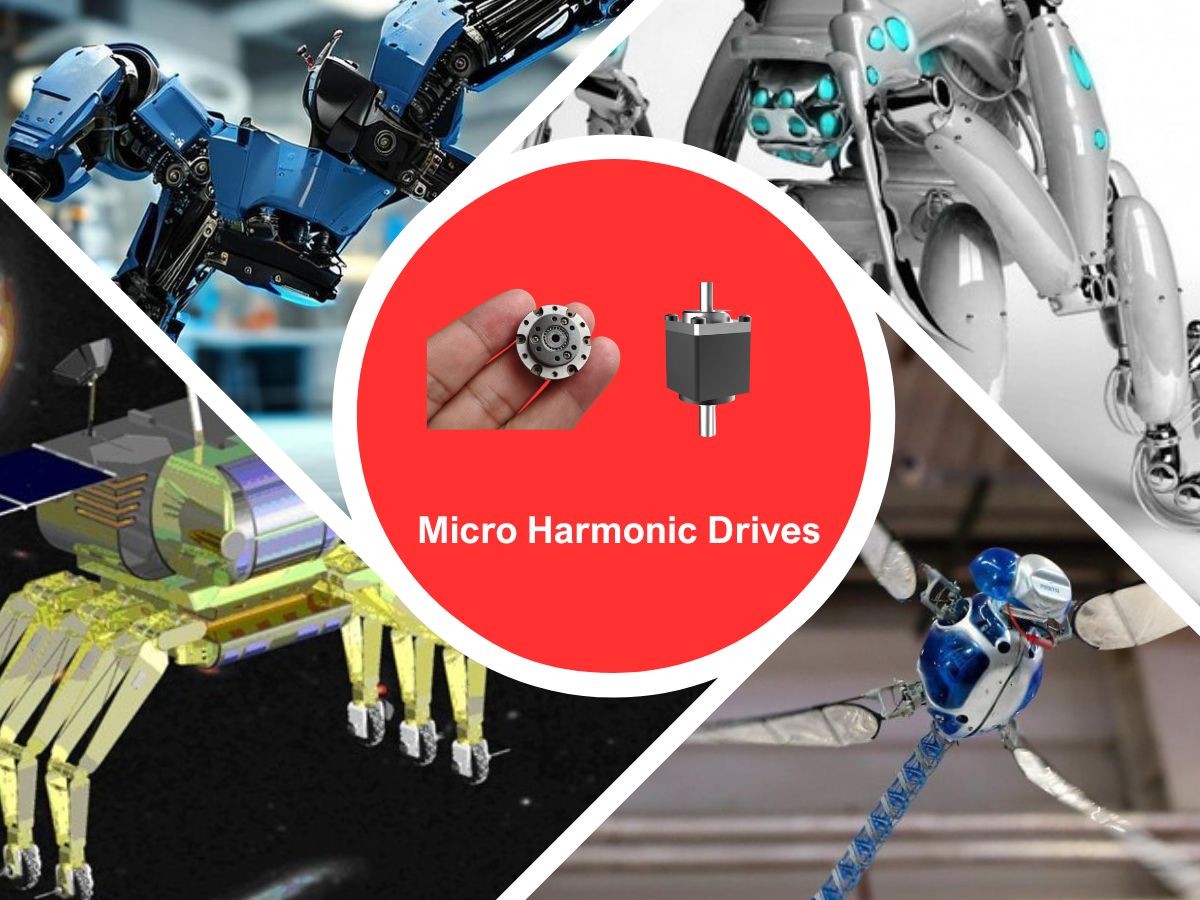

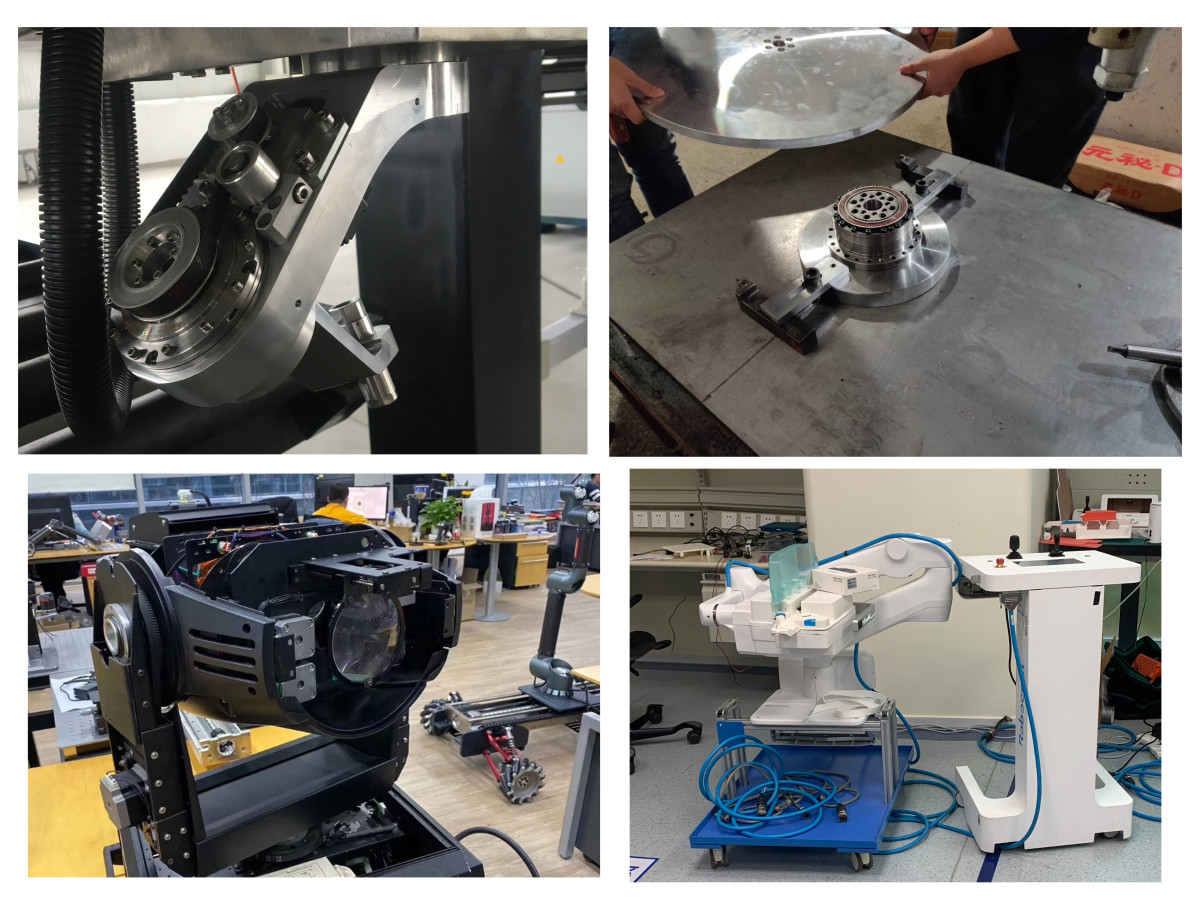

Thanks to its high transmission accuracy, high reduction ratio, compact structure, and low noise, the Harmonic drives are widely used in industrial robots, collaborative robots, CNC machines, automation systems, semiconductor manufacturing equipment, medical devices, and optical instruments—all of which require precise and reliable motion control.As a type of precision transmission device, the Harmonic drives are irreplaceable in specific high-precision fields.

Why Adopt Harmonic Drive Transmission Technology

High-Precision Transmission

Harmonic Drives feature multi-tooth simultaneous engagement, ensuring minimal tooth gap. The backlash can be controlled to below 1 arc-minute, delivering excellent positioning accuracy and repeatability.

High Reduction Ratio

By utilizing the tooth difference between the flexspline and the circular spline, Harmonic Drives achieve reduction ratios from 1:30 to 1:500. This allows for smaller size and lower energy loss compared with other gear systems offering the same reduction ratio.

Compact and Lightweight Design

The overall size of a Harmonic Drive is typically one-third that of a planetary gearbox, with a shorter transmission chain and significantly lower weight—ideal for compact or lightweight applications such as robotic joints and portable automation systems.

High Torque Density

With many teeth engaged simultaneously, the contact area is large and the load distribution uniform, allowing the drive to handle high torque outputs even in small form factors.

Smooth Operation and Low Noise

The flexible cup structure of the flexspline helps absorb shock and vibration, resulting in smooth motion and low mechanical noise—perfect for quiet, precision, or cleanroom environments.

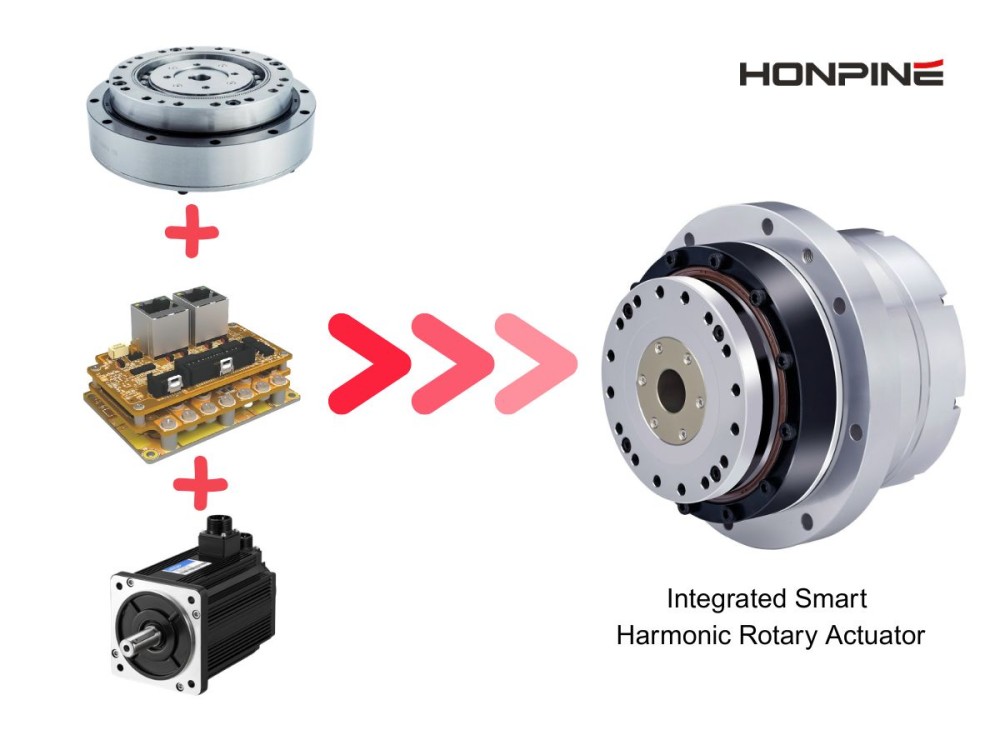

Modular Design Compatibility

Harmonic Drives can be easily integrated with servo motors, encoders, and brakes to create fully integrated joint modules. This modular approach simplifies installation, shortens development cycles, and reduces engineering costs.

Important Considerations for Using Harmonic Drives

Install the Harmonic drive in a clean environment. Ensure that no foreign matter enters the unit to prevent internal damage.

Check the alignment and fit tolerance before installation. The motor shaft and input bore tolerance should be H7/h6. Misalignment or tilt can cause uneven loading and shorten lifespan.

Ensure that the gear surfaces and flexspline bearings are adequately lubricated at all times. Avoid mounting with the tooth side facing upward to maintain effective lubrication.

After installing the wave generator, ensure 180° symmetrical engagement between the flexspline and circular spline. Any deviation may cause vibration and premature wear.

After assembly, perform a low-speed test (around 100 rpm). If abnormal noise or vibration occurs, stop immediately and contact the manufacturer.

Both input and output ends must have proper sealing. For dynamic seals, use lip-type oil seals; for static seals, use O-rings or sealant. Ensure that sealing surfaces are not scratched or misaligned.

If the wave generator faces upward during operation, increase the grease volume to compensate for reduced lubrication efficiency.

Lubricant performance deteriorates with temperature. To maintain long-term reliability, ensure that the temperature at the high-heat end does not exceed 70°C, and that the temperature rise remains below 40°C.

Advantages and Disadvantages of Harmonic Drives

Harmonic Drive vs. Planetary Gearbox

Planetary gearboxes are known for their high efficiency, broad ratio range, and compact construction, making them suitable for automation systems, automotive applications, and printing machinery—ideal where general load and precision requirements apply.

Harmonic Drives, by contrast, are valued for their high precision, high reduction ratio, and ultra-compact design. They are extensively used in robotics, aerospace, medical equipment, and optical instruments, where space constraints and precision control are critical.

Harmonic Drive vs. RV Reducer

In industrial robotics:

RV reducers are suitable for heavy-duty robots (payloads above 20 kg) due to their high rigidity and long service life.

Harmonic Drives are ideal for lightweight robots (below 20 kg payload) or the end joints of large robots, offering a balance of light weight and precision.

Typically, Harmonic Drives are found in collaborative robots, satellite antennas, and optical systems, while RV reducers are preferred in robot bases, CNC indexing tables, heavy-duty automation equipment, and AGV drive wheels.

Why Choose HONPINE Harmonic Drives

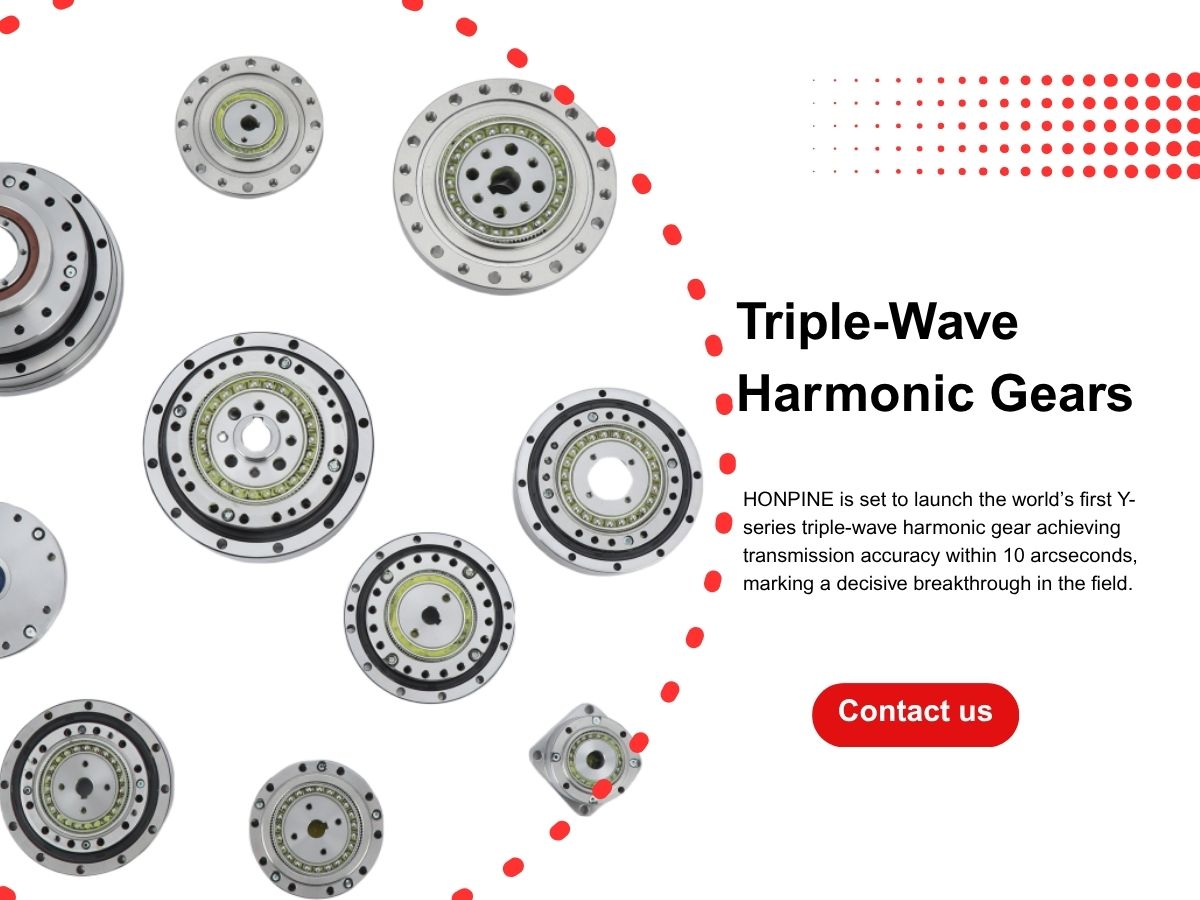

At HONPINE, we have spent more than a decade continuously refining our gear tooth design to deliver higher precision, longer life, and smoother transmission.

We are committed to becoming a global leader in precision motion technology. HONPINE Harmonic Drives are available in a complete range of models and specifications, and have been validated by users in over 50 countries across various industries.

We emphasize both technological innovation and customer service—from model selection and prototyping to after-sales support—offering one-on-one technical assistance to ensure the best performance and user experience.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand