Why harmonic joint modules are still the mainstream of integrated joint modules

In the field of robotics,joint modules serve as core components that determine a robot's flexibility, stability, and operational capability, directly affecting its overall performance and usage costs. Currently, harmonic drive joint modules remain the most mainstream solution in the market.

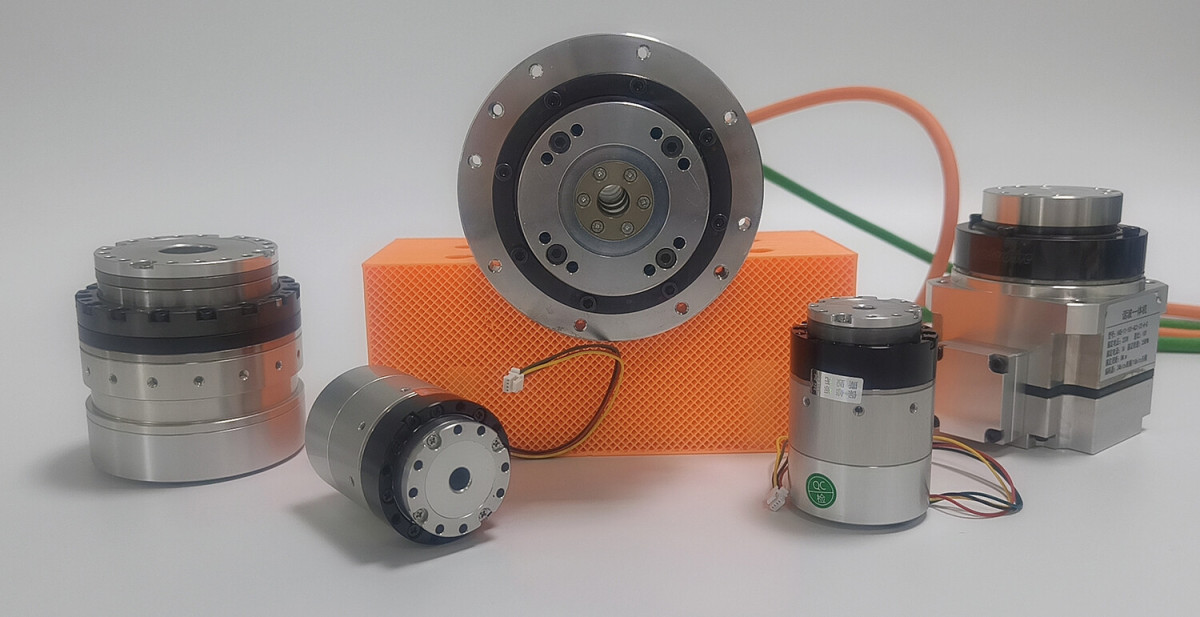

With highly integrated design, harmonic drives work in close coordination with torque motors, sensors, brakes, absolute encoders, and drivers. This not only reduces signal transmission loss but also simplifies installation and maintenance processes, comprehensively meeting industrial production requirements and driving robotics technology to new heights.

Operating Principle of Harmonic Drives in Joint Modules

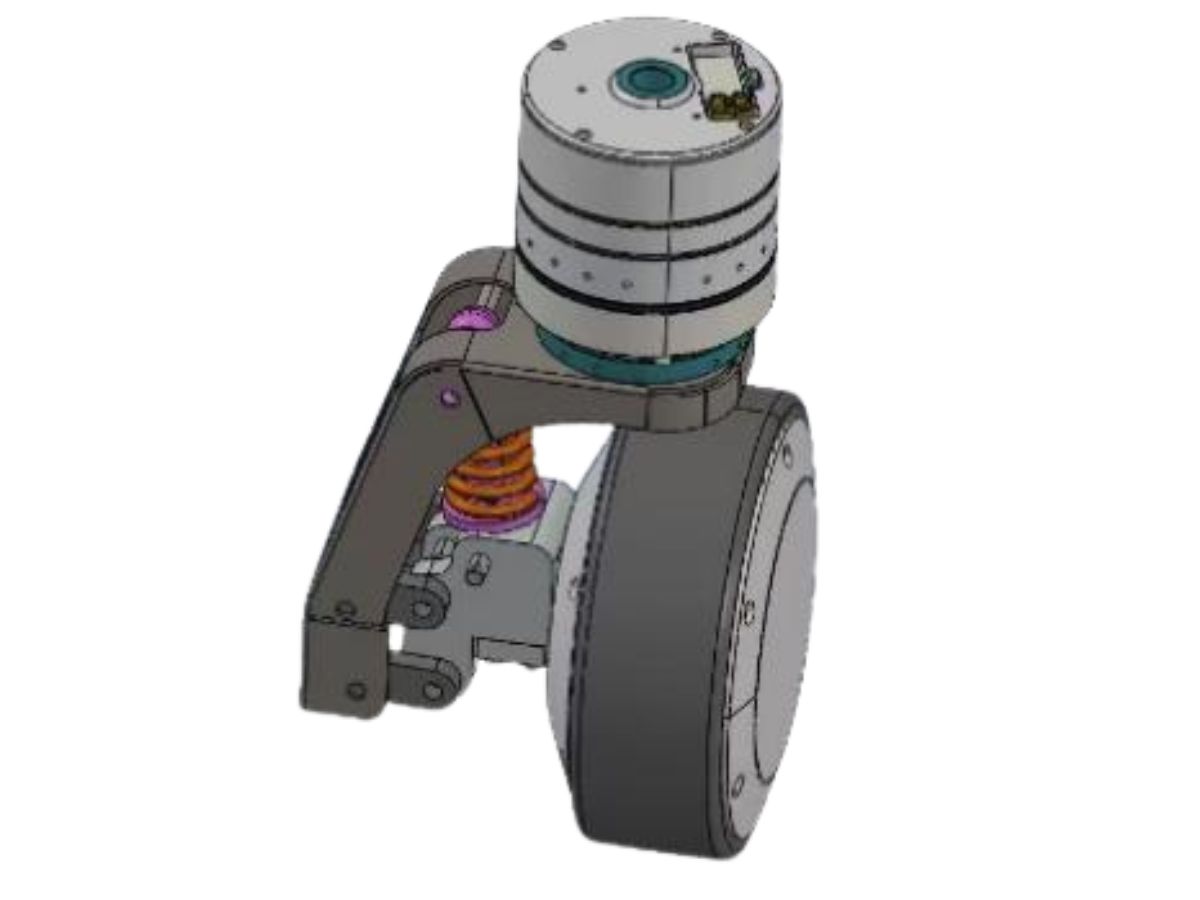

Harmonic drives work in perfect synergy with high-performance torque motors. Through unique friction transmission between the wave generator, flexspline, and circular spline, they convert the motor's high speed into high torque output, with a reduction ratio range of 30-320. In the confined space of robotic joints, harmonic drives significantly improve space utilization with their compact and lightweight advantages while ensuring transmission precision and stability and reducing energy consumption.

Harmonic Drives Leading Technological Innovation

Through in-depth research and improvements in magnetic fields, stator windings, rotor inertia, and structural topology, we have successfully increased motor torque density while reducing rotor inertia. During R&D, servo motors were highly integrated with specially designed harmonic reducers. This innovative design enables the integration of multiple functional components - including high-precision input/output encoders, output torque sensors, drive control units, and temperature sensors - in an extremely compact and lightweight package, greatly enhancing overall reducer performance.

Advantages of Harmonic Drive Joint Modules

The main structure of joint modules features IP67 protection, with special customized models reaching IP68, enabling stable operation in various complex environments. Additionally, they achieve 360° continuous rotation, greatly expanding application scope, especially for scenarios demanding extreme robot lightweighting. They achieve 50% weight reduction, approximately 50% size reduction, yet with about 50% torque increase, perfectly balancing product size, weight, and torque.

Application Scenarios of Harmonic Drive Joint Modules

Thanks to their outstanding performance, these reducers are widely used in robotics. In humanoid robots, they provide strong technical support for flexible and precise movements. For collaborative robots, we've simultaneously launched ultra-lightweight cobots with a 2:1 payload-to-weight ratio - weighing about 8kg but with 600mm effective working radius, 10kg full-arm-span rated payload, and over 15kg maximum payload. Each joint of this robotic arm contains brakes and integrates multiple advanced technologies, suitable for emerging automation markets like unmanned delivery, retail, food service, medical care, and agricultural harvesting.

Due to their superior performance, harmonic drives have become the preferred choice for mainstream joint module manufacturers. Although slightly more expensive than planetary gear joint modules, harmonic drive joint modules remain the market mainstream. Contact HONPINE for comprehensive application analysis to select the most suitable joint module based on technical specifications and actual requirements.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand