The Secret Behind HONPINE High-Precision Planetary Reducers' Ultra-High Quality

Since 2018, HONPINE's high-precision planetary reducers have thrived in competitive markets, earning widespread customer recognition for their unique structure, craftsmanship, and exceptional precision, strength, and longevity. HONPINE planetary reducers can replace most leading brands, including STOBER, WITTENSTEIN, and NEUGART. Here’s how HONPINE achieves this.

Superior Structural and Process Advantages

●Integrated Housing Design

The inner ring gear is embedded in the front housing, optimizing connection and ensuring gear train precision even at high speeds. The nickel-plated housing surface enhances corrosion resistance in harsh environments.

●Planetary Carrier and Output Shaft Integration

Eliminates secondary connection precision loss. Single-clamping and single-processing guarantee perfect coaxiality, ensuring smooth, efficient planetary gear operation.

●Sun Gear Input Shaft Integration

Reduces mechanical connections, improves torque transmission, and maintains overall reducer precision.

●Premium Gear Material

Custom-made chromium-manganese-titanium alloy steel from Japan, with surface hardness of HRA80-83 for superior wear resistance and impact toughness.

●Torsional Rigidity

The integrated planetary carrier and output shaft maximize torsional rigidity with planetary gears.

●Input Connection

Uses a collet-type locking mechanism for motor attachment.

High Performance and Precision

1,Accuracy:

Single-stage: 1–3 arc minutes

Dual-stage: 3–5 arc minutes

2,Torque Capacity:

Emergency stop torque: 3× rated torque

Maximum torque: 60% of emergency stop torque

3,Noise Level:

≤65 dB (high-precision models).

4,Operating Temperature:

-10°C to 90°C (high-temperature models: -40°C to 150°C).

5,Service Life:

20,000–30,000 hours (1.5 years continuous operation).

6,Lubricant:

Synthetic grease (Japan Kyodo Oil).

7,Mounting:

Supports any orientation.

8,Protection Rating:

IP64.

9,Bearings:

Fully filled needle roller bearings (no retainer); custom needle rollers with ≤2μm tolerance.

10,Durability:

Nickel-coated housing for corrosion/wear resistance; ground shafts for higher precision.

11,Market-Proven and Customer Approved

HONPINE planetary reducers have been exported globally, earning trust across industries.

Case Study 1: Aluminum Profile Linear Module Machining Center

Model: NFG Series planetary reducer with gears.

Performance: 0.02mm repeatability accuracy.

Applications: New energy vehicles, electrical trays, rail transit, CNC gantry machining centers.

Materials: Steel, aluminum, copper, and non-metallic materials.

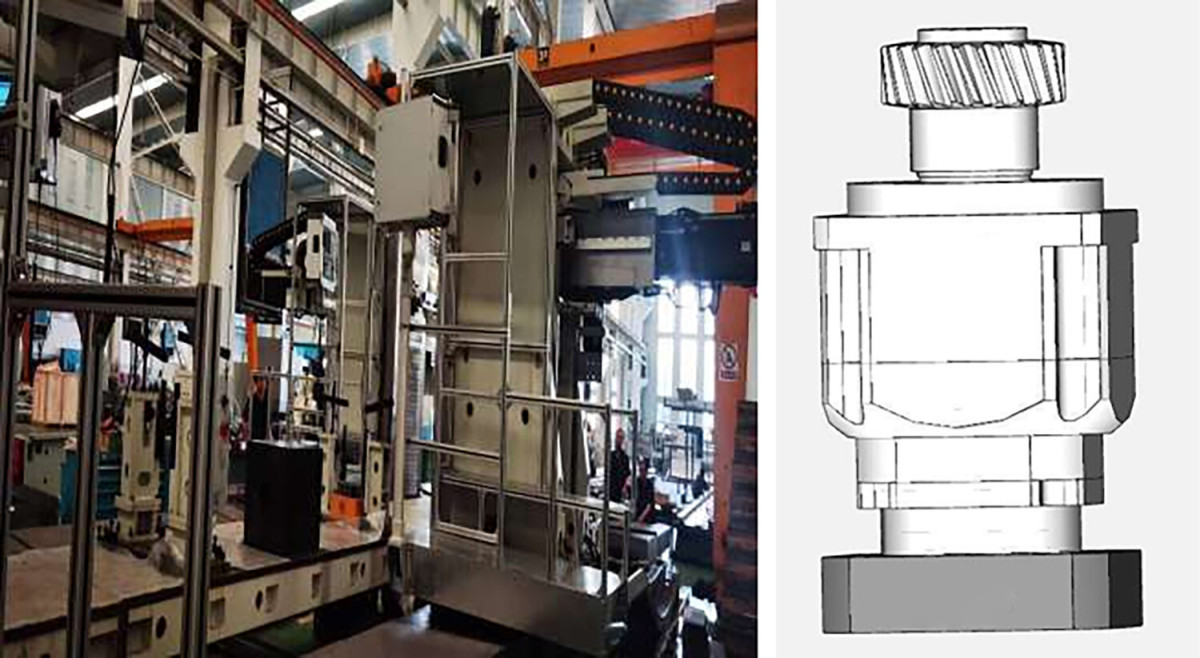

Case Study 2: CNC Gantry Machining Center

Models: Mixed NF and NB series reducers.

Applications: Heavy/medium box/shell structural parts, aerospace components, machine base parts.

Case Study 3: Heavy-Duty Gantry Boring and Milling Machine

Models: Mixed NFG and NBG series reducers.

Case Study 4: Modular Machining Center

Models: NBG and NDVG series, including NDVG200-90-P0/4M20Z dual anti-backlash reducer.

Applications: Heavy-duty housings, large aerospace parts.

Case Study 5: Horizontal Lathe Machining Center

Models: NDVG series with gears, NDVG140-40-P1/4M12Z dual anti-backlash reducer.

Applications: Heavy cylindrical/conical parts, grooves, and curved surfaces.

Contact us to learn more about HONPINE planetary reducers!

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

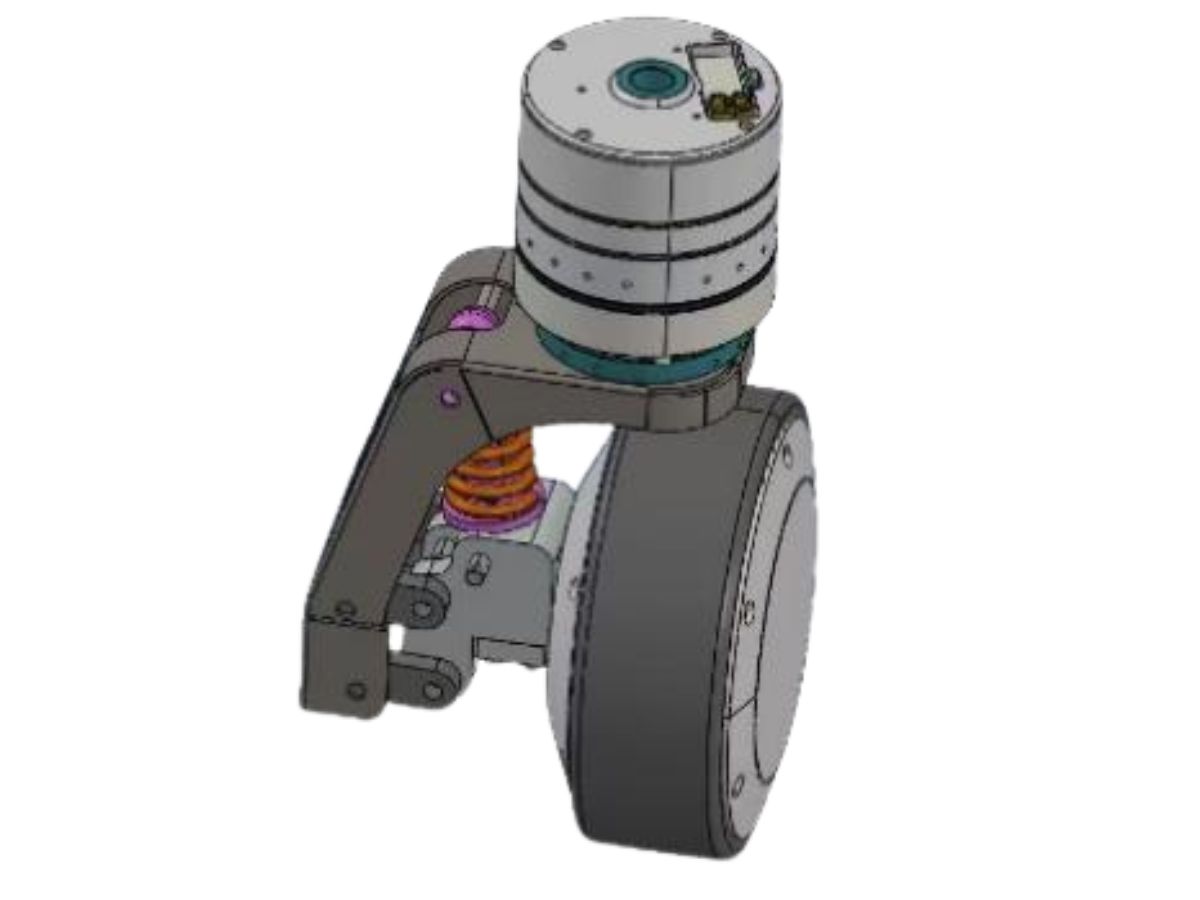

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand