Harmonic Drive and Servo Motor Synergy Accelerates Robotic Arm Miniaturization

With the continuous development of robotics, servo control systems are playing an increasingly important role in complex working environments. A coordinated control strategy combining servo motors and harmonic drives improves the system’s dynamic performance and control accuracy. The Harmonic Drive + Servo Motor pairing is the core solution for achieving miniaturization, lightweight design, and high precision in industrial and collaborative robots.

How Servo Motors and Harmonic Drives Work Together

Servo motors provide high-speed, low-torque, and precise drive capabilities, enabling accurate control of speed and angle. Harmonic drives, featuring zero backlash and high precision, ensure repeatable positioning accuracy of robot joints, amplify torque, and enhance output rigidity.

The Role of Harmonic Drives in Robot Joints

In joint servo systems, the motor output shaft is connected to the load through a harmonic drive. The transmission relationship between speed and torque across the input and output shafts is determined by the harmonic drive’s structure. Inevitably, joint friction exists, which leads to efficiency loss and reduced compliance, but it also provides a beneficial damping effect. In practice, the impact of friction is optimized through lubrication, compensation via control algorithms, and force sensors.

Applications of Harmonic Drives and Servo Motors

Collaborative Robots

The servo motor directly drives the harmonic drive, forming an integrated joint module. Only low speed and torque from the servo motor are required to meet end-effector demands. This is especially suitable for lightweight robots with more than six degrees of freedom. Examples include UR, AUBO, and JAKA collaborative robots.

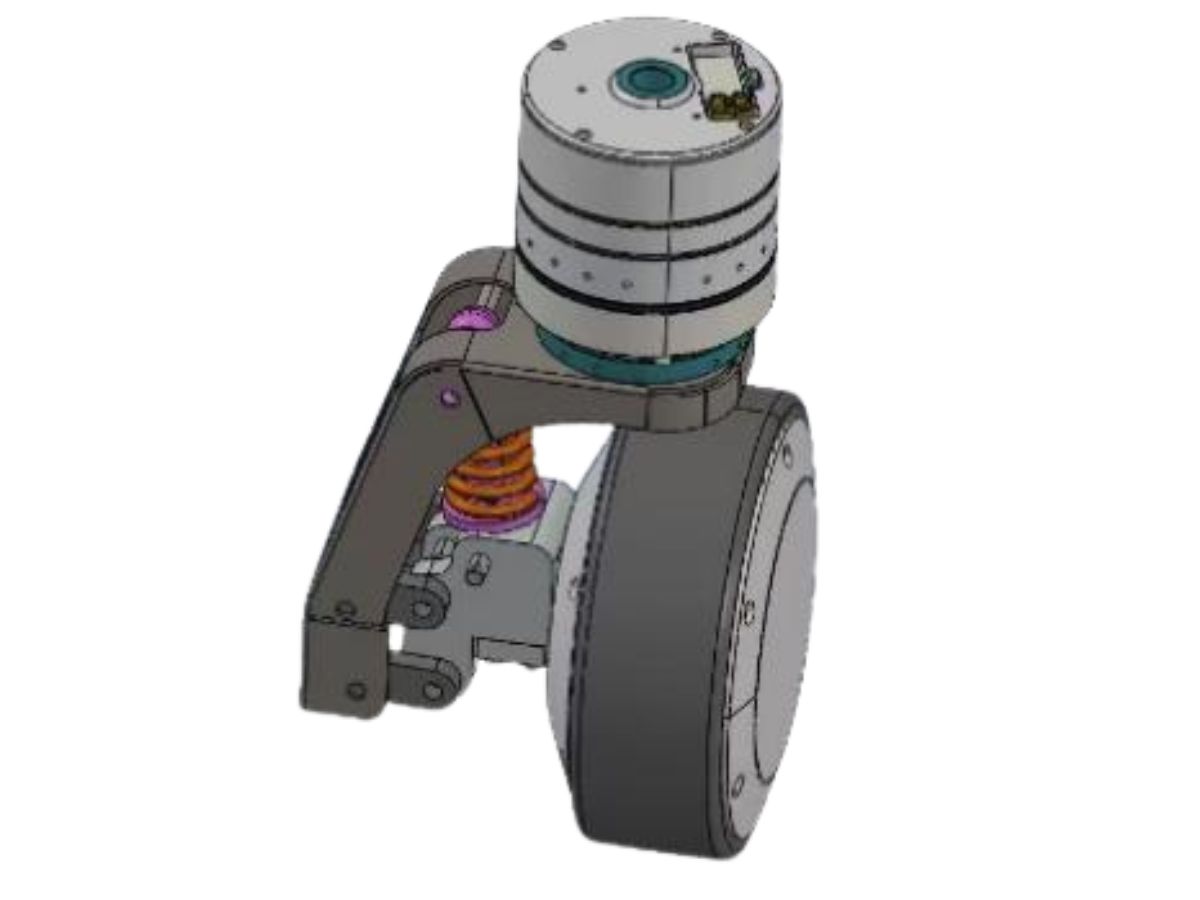

Humanoid Robot Leg Joints

The high reduction ratio of harmonic drives enables small motors to deliver the torque required for humanoid walking, ensuring sufficient power within limited joint space. Examples include UBTECH Walker, Xiaomi CyberOne, and Tesla Optimus.

Precision Positioning Platforms

The combination of servo motors and harmonic drives achieves ultra-high-resolution angular positioning. Paired with high-resolution encoders, it can reach sub-arcsecond accuracy. This is widely used in equipment requiring extreme repeatability, such as semiconductor and optical inspection systems.

Aerospace

The servo motor and harmonic drive combination delivers long-term stable low-speed, high-torque output. Since spacecraft are weight-constrained, the compact design of harmonic drives is highly suitable. Typical applications include satellite solar panel deployment and radar antenna actuation.

Medical Robots

The harmonic drive–servo motor pairing enables smooth, backlash-free, high-precision operation. The servo motor drives the harmonic reducer to achieve low-speed, high-precision control, while the harmonic drive ensures accurate force feedback during surgical manipulation.

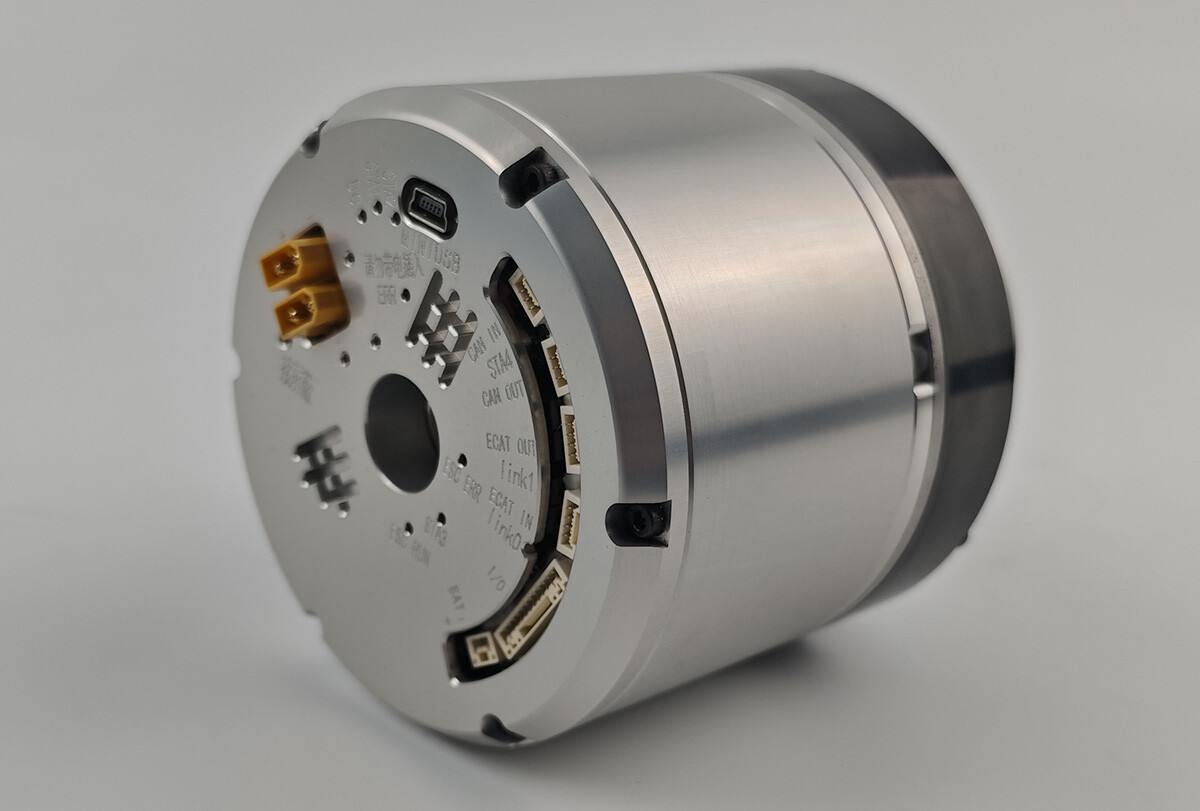

Harmonic Servo Joint Modules as a Market Trend.

Harmonic joint modules integrate the harmonic drive, servo motor, encoder, and driver into a compact unit. HONPINE’s harmonic joint modules deliver higher torque output within limited space, maximizing the advantages of both the harmonic drive and servo motor.

Robots are widely applied in global industrial manufacturing, where the core functional components of their motion systems are harmonic servo joint systems. These systems ensure robot joints meet performance requirements for high-precision torque and speed control. Due to their miniaturization, high precision, and ease of integration, harmonic servo joint modules are becoming the mainstream trend of the future.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand