The Best Servo Hub Wheel Motor for AGVs and Service Robots

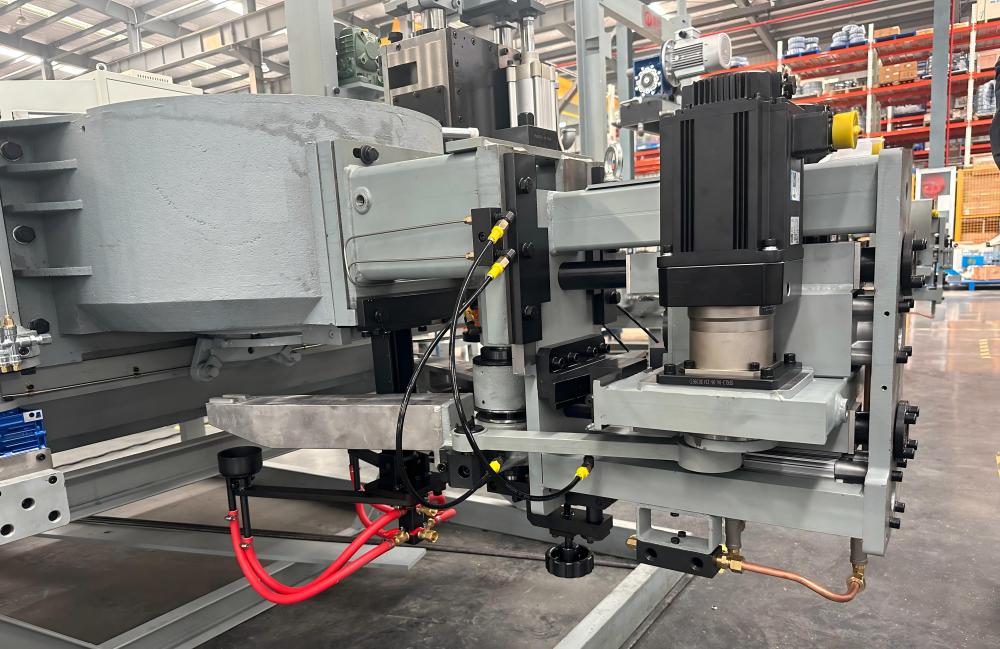

A robot servo hub motor is a new type of drive solution that integrates the motor and transmission system directly into the wheel hub. This innovative design fundamentally changes the traditional power transmission structure of mobile platforms and robots. Hub motors are widely used in various robotic applications.Designed for mobile scenarios such as service robots, AGVs, and medical equipment, the HONPINE iSML Series Integrated Servo Hub Motor stands out with its all-in-one design and powerful performance, providing stable and reliable driving force for mobile devices.

Advantages of the HONPINE iSML Servo Hub Motor

Integrated Design

Motor, encoder, and drive are integrated into a single compact unit, saving installation space, simplifying system layout, and reducing assembly complexity.

Easy Communication

Supports the CANopen protocol. CAN BUS baud rate up to 1 Mbps, with an RS485 debugging port supporting 115.2 Kbps, ensuring high compatibility with various control systems.

Strong Environmental Adaptability

Operating temperature: 0–40°C

Storage temperature: –20–60°C

Humidity tolerance: ≤90% RH (non-condensing)

Suitable for most indoor and outdoor applications.

Safe and Stable Operation

Equipped with over-voltage (DC 68V ±2V) and under-voltage (DC 18V ±2V) protection alarms.

Operating noise level <65 dB.

Natural air-cooling design ensures quiet and reliable operation.

High Load Capacity

Rated operating altitude: ≤1000 m

Maximum operating altitude: 2000 m

Above 1000 m, power derates by 1.5% per 100 m, allowing operation in different altitude environments.

Core Performance Highlights

Rated torque: 8.5 Nm,Peak torque: 25.5 Nm,Strong driving force for heavy-load applications.

IP65 protection rating, providing excellent dustproof and waterproof performance.

Key Specifications

Tire diameter: 140 mm,Rated voltage: 48 VDC,Rated current: 5.5 Arms,Maximum speed: 320 rpm

Output shaft diameter: 12 mm (double-flat), bore Φ7.5 mm

Application Areas of the HONPINE iSML Servo Hub Motor

Service Industry

Cleaning, disinfection, inspection, delivery, and guidance service robots.

Logistics & Warehousing

Small AGV systems for material handling, transportation, and loading/unloading tasks.

Medical Equipment

Power drive for various mobile medical devices.

Why Choose HONPINE Servo Hub Motors?

Compared with traditional motors and transmission systems, hub motors integrate the power source directly into the wheel, significantly reducing the number of mechanical transmission components. This improves overall system efficiency and reliability. The design also enables robots to move more flexibly and adapt to complex working environments.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

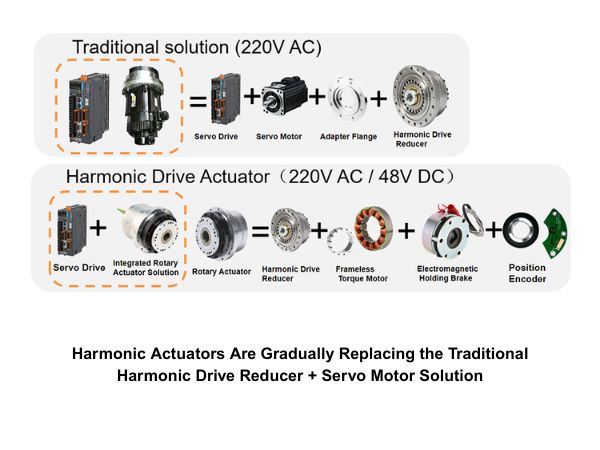

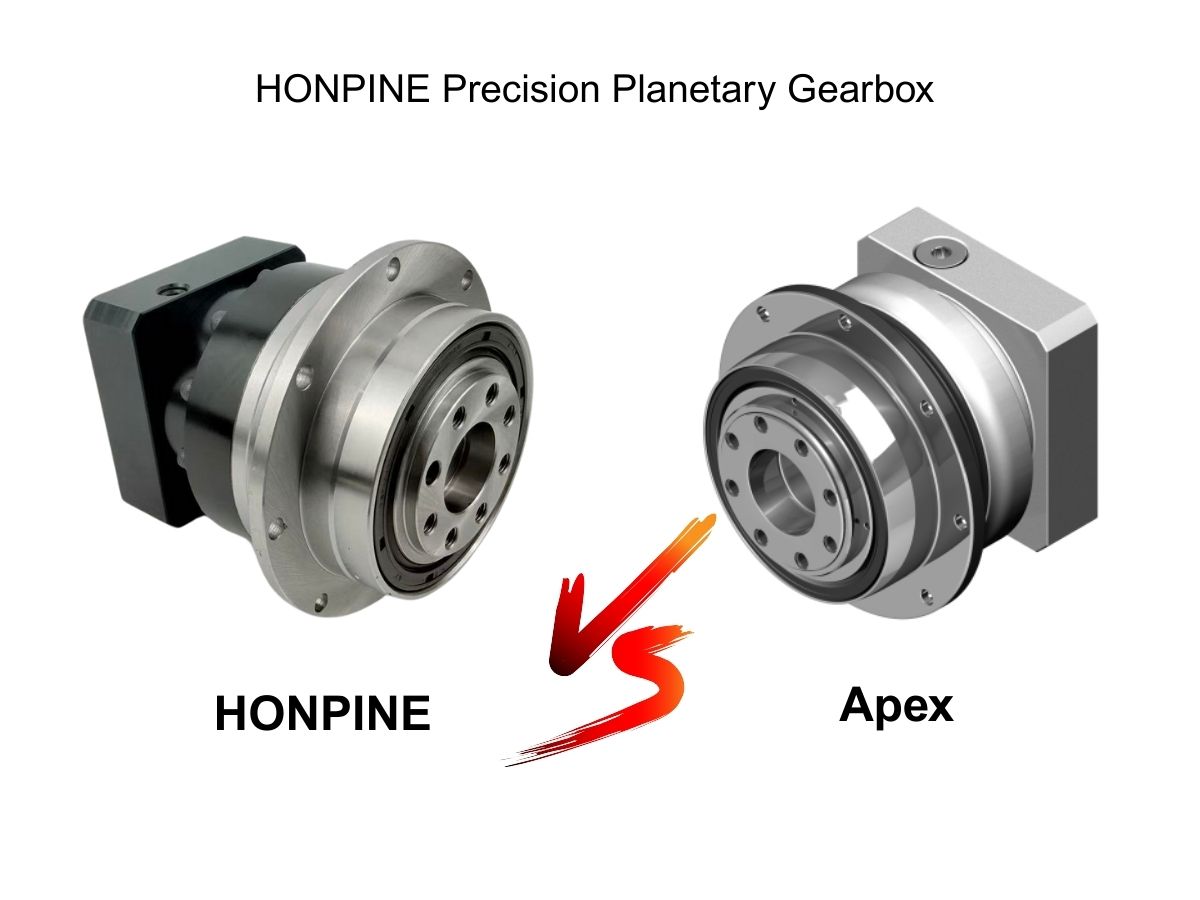

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand