HONPINE Easter invites you to paint colorful dreams together, the future of precision transmission

HONPINE organized an employee painting event on Easter. At the party, everyone painted colorful eggs together. The eggs symbolize rebirth and resurrection. In this event, everyone painted the colors of the future in their hearts. HONPINE is using precision transmission technology to help customers change the future.

HONPINE's customers are technology leaders in various industries.

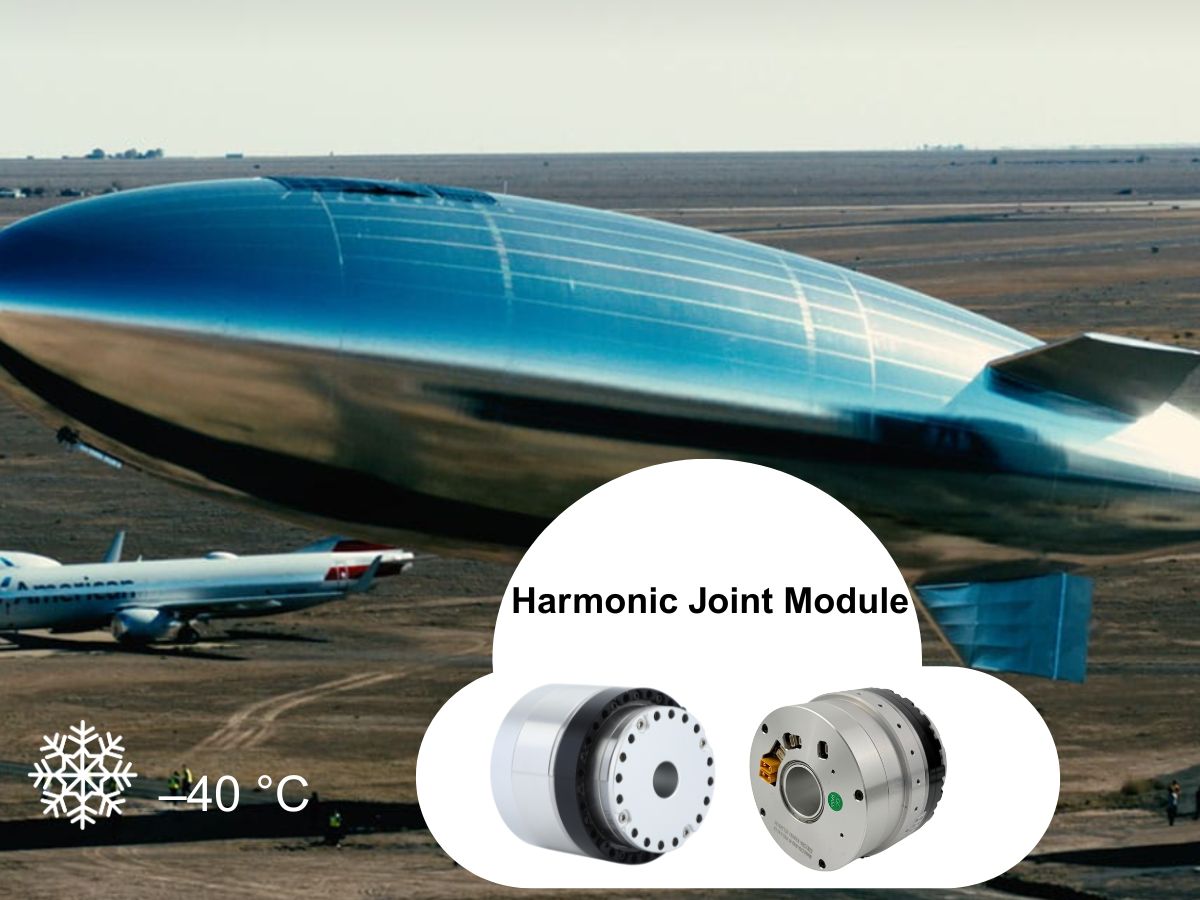

Aerospace

Harmonic reducers and joint modules for aerospace must have a high single-stage reduction ratio, lightweight and compact design. HONPINE provides customers with solutions through special processing.

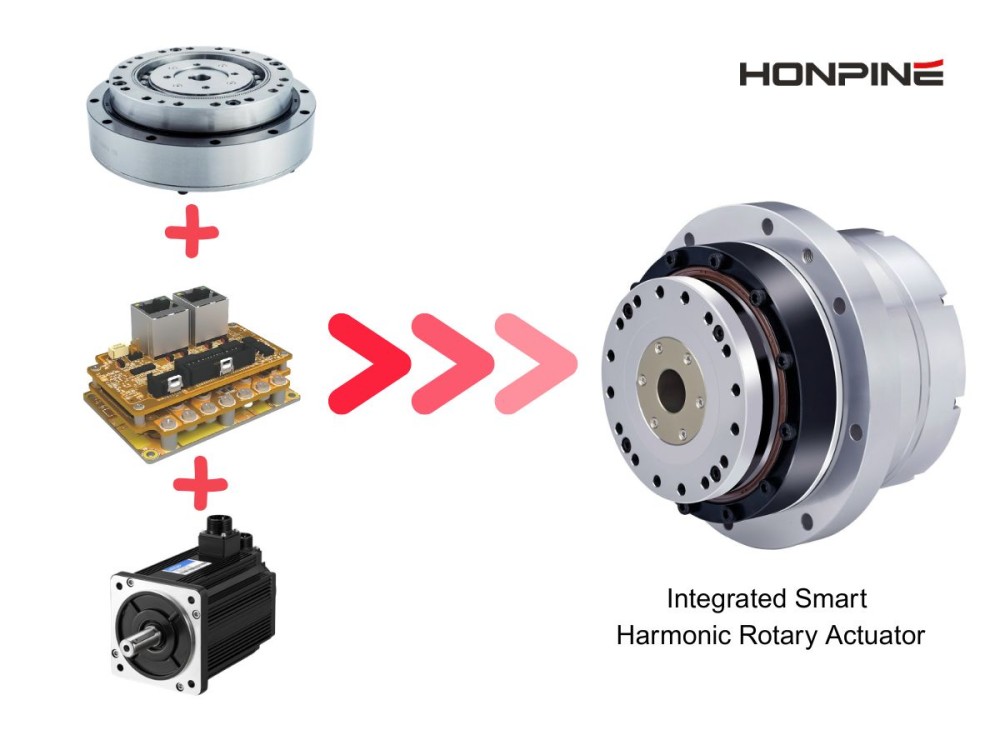

Humanoid robots

The development of humanoid robots is showing a diversified trend, such as semi-humanoid robots designed for the commercial field: the lower body uses wheels to improve mobility efficiency, and the upper body can coordinate arm and hand movements. With the advancement of AI technology, humanoid robots of different complexities can be adapted to different scenarios.

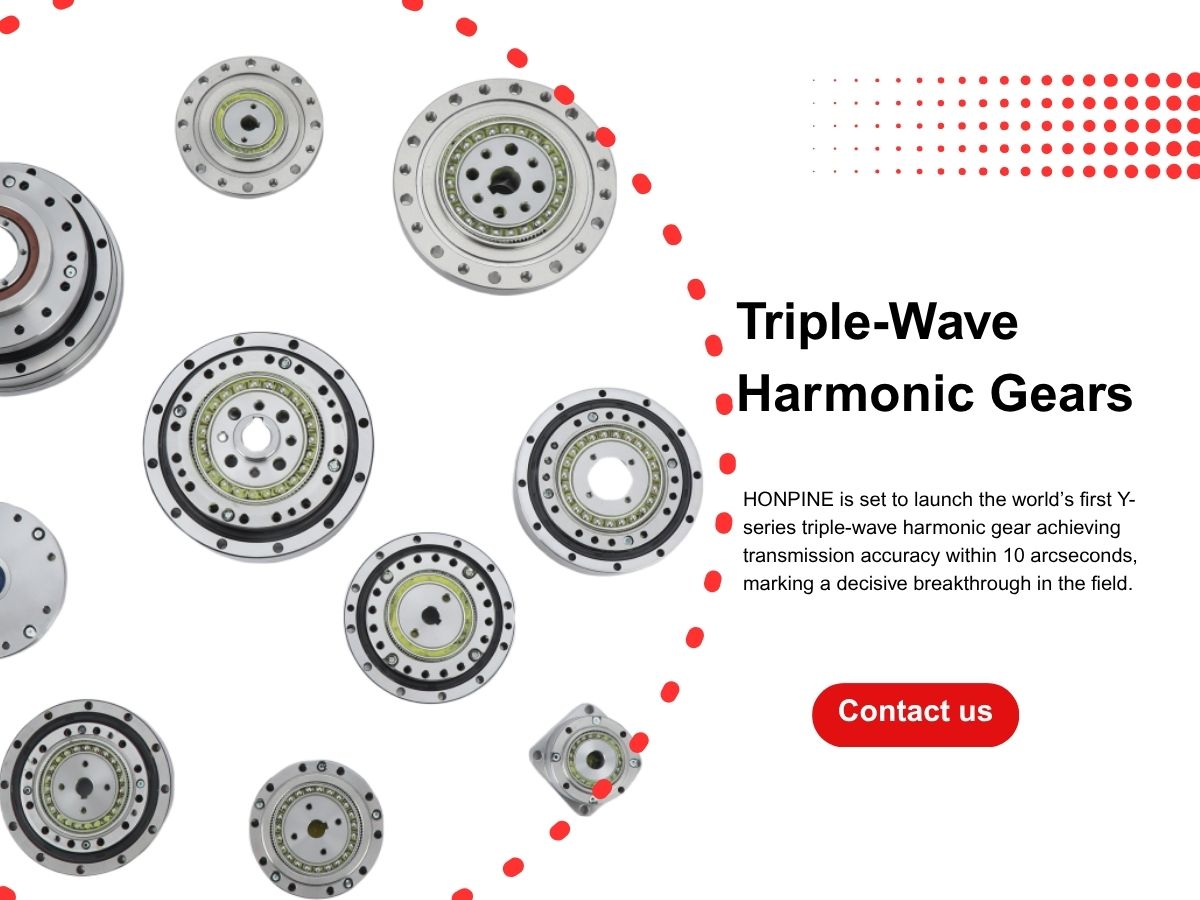

Optical equipment

Harmonic gears are required for workbench positioning, lens driving and sensor positioning in optical equipment. Optical measurement systems can scan the contour of the sample without the probe touching the surface, so the gearbox accuracy requirements are extremely high.

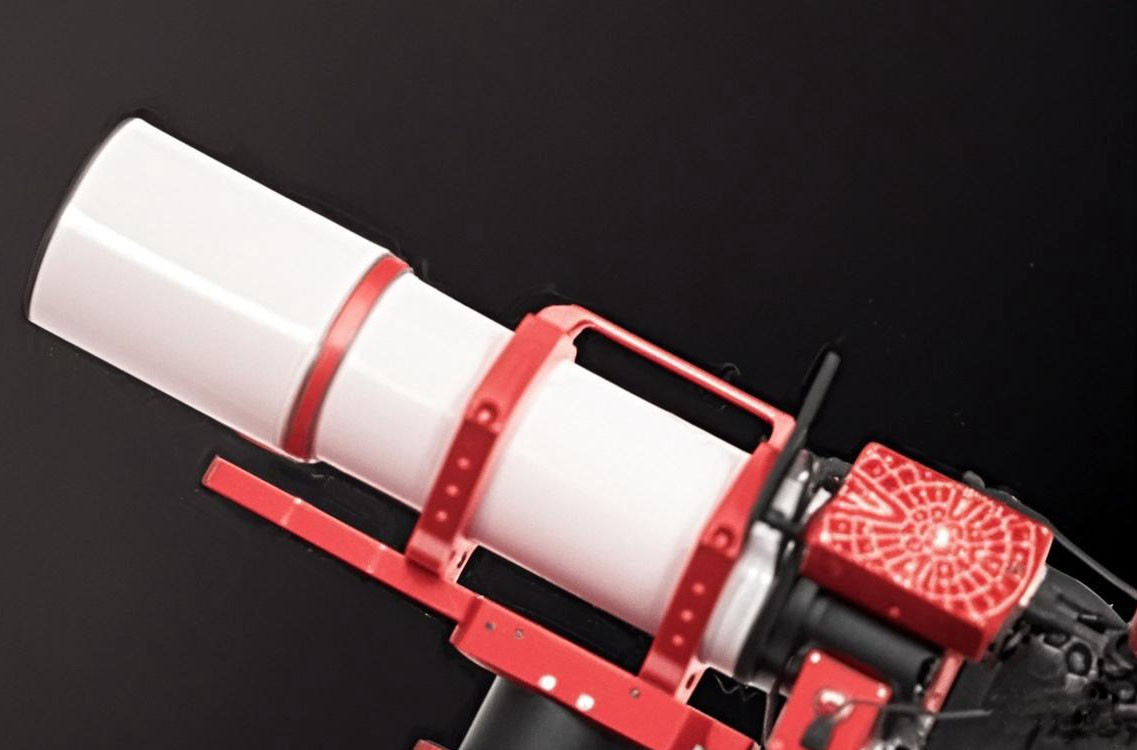

Optical Reflecting Telescope

Harmonic reducers help optical telescopes accurately track the movement of celestial bodies with their high precision, high speed ratio, small size and low starting torque.

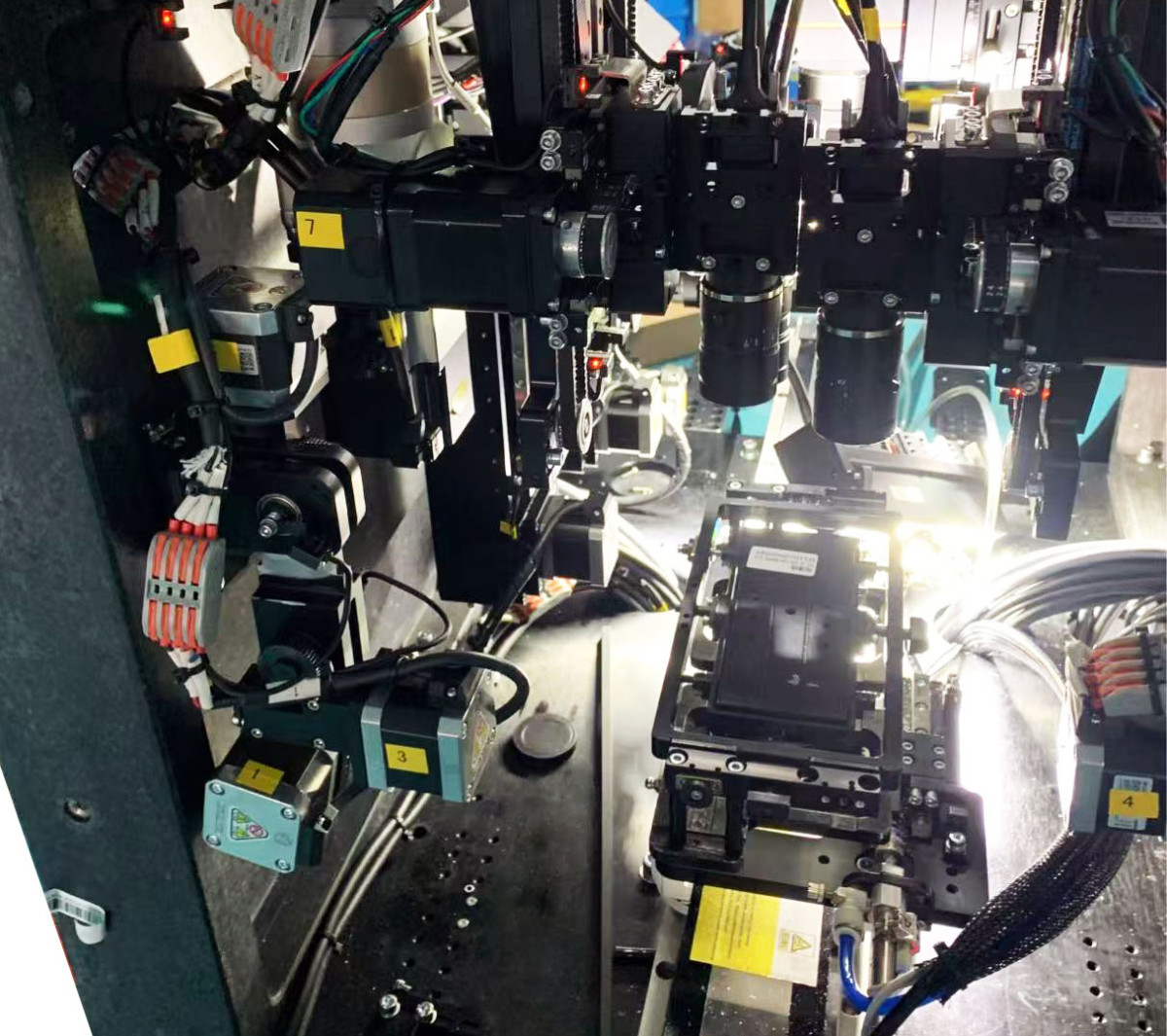

Semiconductor Equipment

High-precision hollow shaft harmonic reducer joint modules are widely used in semiconductor equipment, such as:

Wafer-handling Robot Primary Axes

Wafer-Loading Device Primary Axes

Crystal Pulling Machine

Two-Speed Range Actuator

Coating Machine Rotary Table Drive

The hollow shaft design can be built-in with cables or installed on the robot base to reduce the weight of the robot arm. HONPINE can provide the best solution according to the equipment requirements.

Printed Circuit Board Equipment

With the improvement of electronic information processing capabilities, printed circuit boards have increasingly stringent requirements for precision. Harmonic reducers are widely used in milling head drives, tool positioning systems, rotary tables and other equipment with their advantages of small size, light weight and high precision.

The application areas of harmonic reducers and joint modules are still expanding. The future is full of possibilities like Easter eggs, waiting for us to create together.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand