Linear Actuators vs Rotary Actuators: The Core Choice for Humanoid Robot Joints

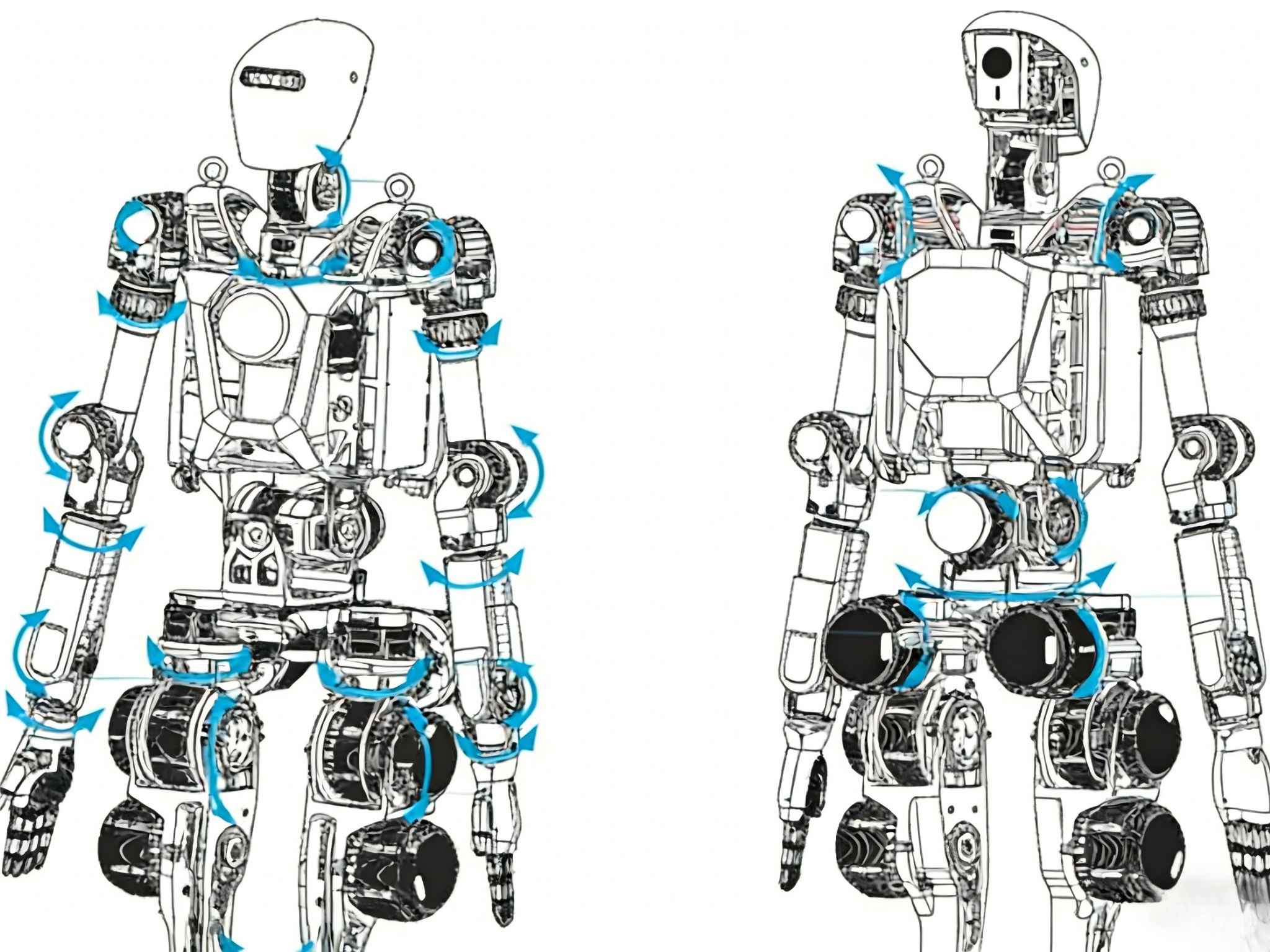

The robot joint module is the core hardware of humanoid robots, currently mainly divided into two major categories: rotary and linear. In humanoid robot designs, the choice often involves trade-offs based on the application scenario and manufacturing cost.

The Fundamental Difference Between Linear and Rotary Actuators

Rotary Actuator: Multiple Reducer Solutions Meet Humanoid Body Functional Requirements

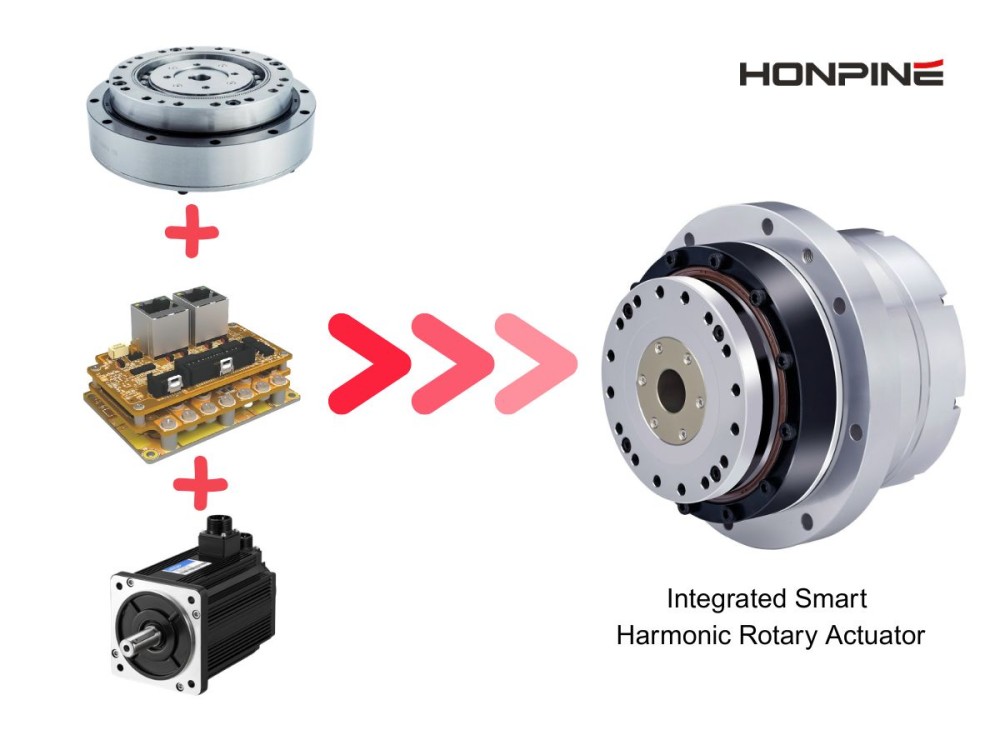

A rotary actuator consists of a motor (frameless torque motor), a reducer (harmonic drive, planetary gear reducer, cycloidal pinwheel reducer), sensors (torque sensor), an encoder, and bearings (crossed roller bearings, angular contact ball bearings).

Precision Planetary Gear Reducer: Suitable for body parts with high loads and strong impact; the manufacturing process is relatively mature. In terms of processing technology and equipment, it can be updated to high-precision CNC machine tool solutions.

Cycloidal Pinwheel Reducer: Features a structure combining a primary planetary stage and a secondary cycloidal pinwheel stage, allowing flexible adjustment to meet the requirements of different body parts. There is a trend of acceleration in new model design and iteration, with some manufacturers developing targeted lightweight processes.

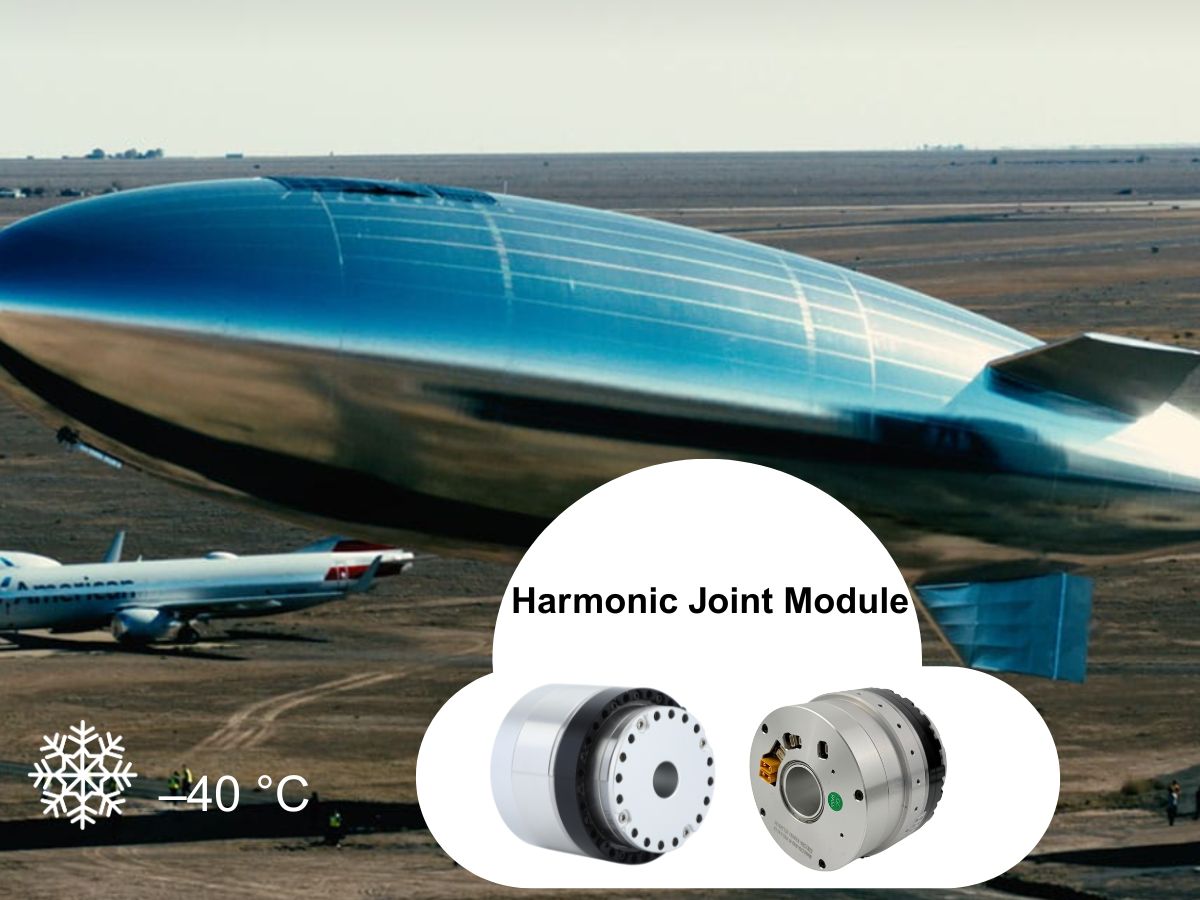

Harmonic Drive Reducer: A high-precision, lightweight reducer suitable for locations like the upper limbs of humanoids. Innovations in manufacturing processes include the application of fine blanking for core reducer components and the manufacturing of micro-reducer parts.

Linear Actuator: Motor + Linear Components - How Push/Pull Enables Robot Motion + Load?

A linear actuator consists of a motor (frameless torque motor), a screw (planetary roller screw, ball screw), and sensors (torque sensor).

Due to existing machining difficulties, micro-reducers for dexterous hands primarily use lead screws or ball screws. Larger-sized actuators may utilize planetary roller screw solutions.

Ball screw technology is relatively mature; the difficulty in processing lies in machining the internal raceway of the nut, especially avoiding grinding wheel interference in nuts with large leads.

Planetary roller screws are categorized into standard type, inverse type, etc. Machining processes include grinding and turning as a substitute for grinding.

Differences in Application Scenarios for Linear and Rotary Actuators

Rotary Actuators enable rotation around a single axis, outputting rotational motion, allowing humanoid robots to perform various angled rotational actions. They are typically used in joints requiring high torque, such as shoulder joints, the waist, and hip joints.

Cost Perspective: Within the rotary actuator, the harmonic drive, torque sensor, and frameless torque motor account for relatively high cost shares, approximately 36.0%, 30.0%, and 13.5% respectively, collectively comprising about 79.5% of the rotary actuator's cost.

Linear Actuators convert the motor's rotational motion into linear motion output, offering good support performance and load-bearing capacity. They are mainly used in scenarios with high loads and small rotational motion angles, such as the knees, elbows, and ankles.

Cost Perspective: In linear actuators, the planetary roller screw, force sensor, and frameless torque motor account for relatively high cost shares, approximately 64.2%, 16.1%, and 7.2% respectively, collectively comprising about 87.5% of the linear actuator's cost.

Advantages and Disadvantages of Linear and Rotary Actuators

Rotary Actuators: The production and application of rotary actuators are relatively mature and have been validated in the global market. They are suitable for large-angle rotation joints like shoulders and hips. They offer high transmission efficiency, and their transmission accuracy can meet the requirements of most humanoid robots. Compared to linear actuators, rotary actuators possess stronger dynamic characteristics and a high degree of integration.

Linear Actuators: The planetary roller screw in linear actuators can easily achieve maintained stiffness and zero-backlash transmission through pre-loaded nuts. Due to line/area contact, planetary roller screws maintain good stiffness, which is more beneficial for delicate and stable operations of the upper limbs.

However, linear actuators have weaker dynamic characteristics: Due to the high reduction ratio, the output speed is relatively low under the same power density, and the passband is narrow, which is not conducive to achieving high-dynamic movements (compared to planetary reducer joints or hydraulic drives).

Furthermore, system integration is relatively low, and costs are high. The joint end cannot perceive external forces through the current loop method; force control must rely on an additional force sensor installed at the joint end, resulting in lower system integration and higher costs.Currently, the RVI (Inverted Planetary Roller Screw) configuration used by Tesla presents significant challenges in machining technology.

Both linear and rotary actuators have their own advantages in terms of motion form, structural characteristics, performance parameters, and application scenarios. Currently, rotary actuators, especially harmonic drive rotary actuators, remain the mainstream choice in the market. Selecting the correct actuator is a key decision in humanoid robot research and development.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand