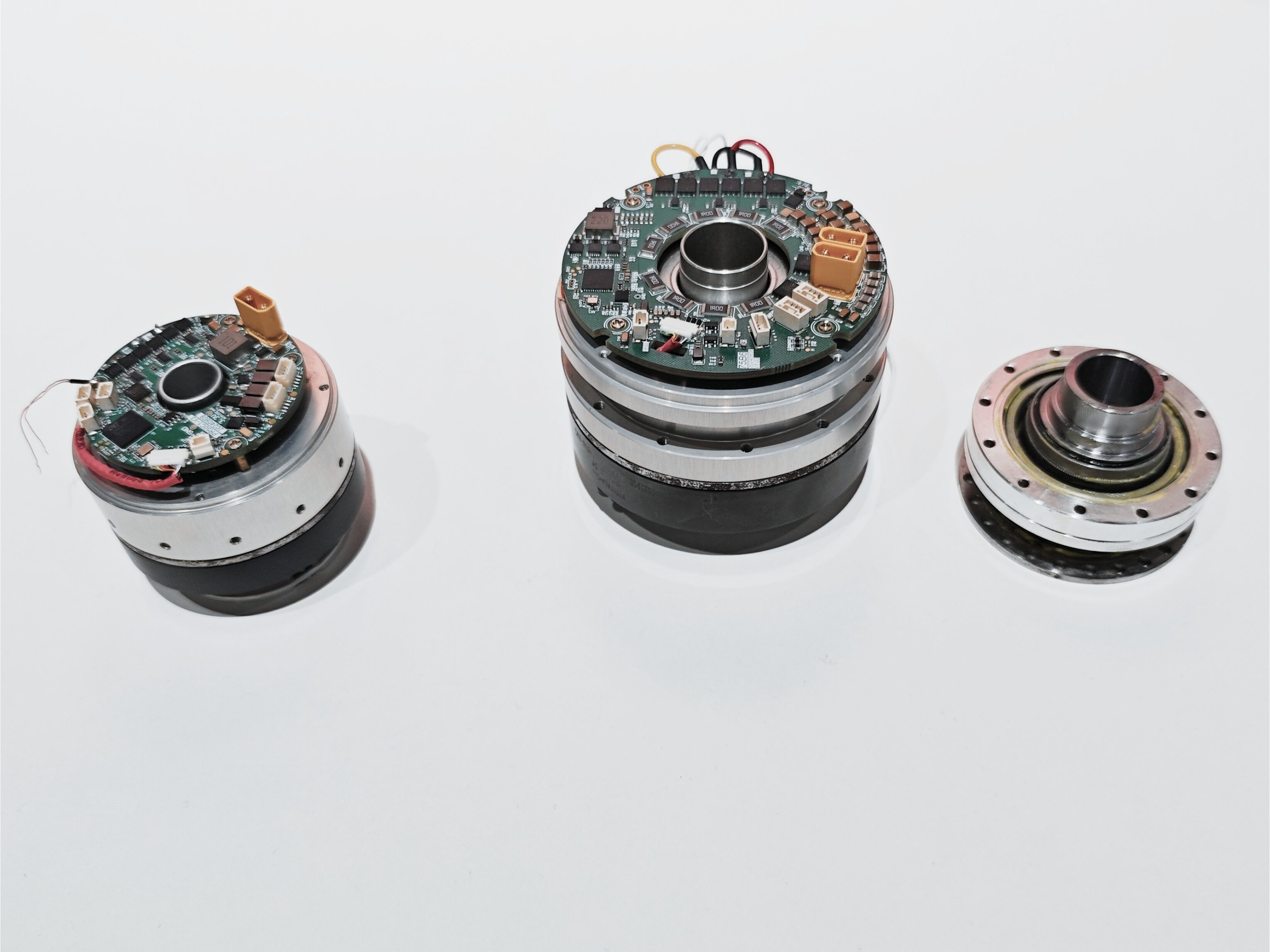

At present, more than 90% of robot joint modules on the market adopt harmonic drives or planetary reducers. The cycloidal reducer, however, is just beginning to be tested in humanoid robot joints in China and has not yet been fully validated by the market.

Application Scenarios

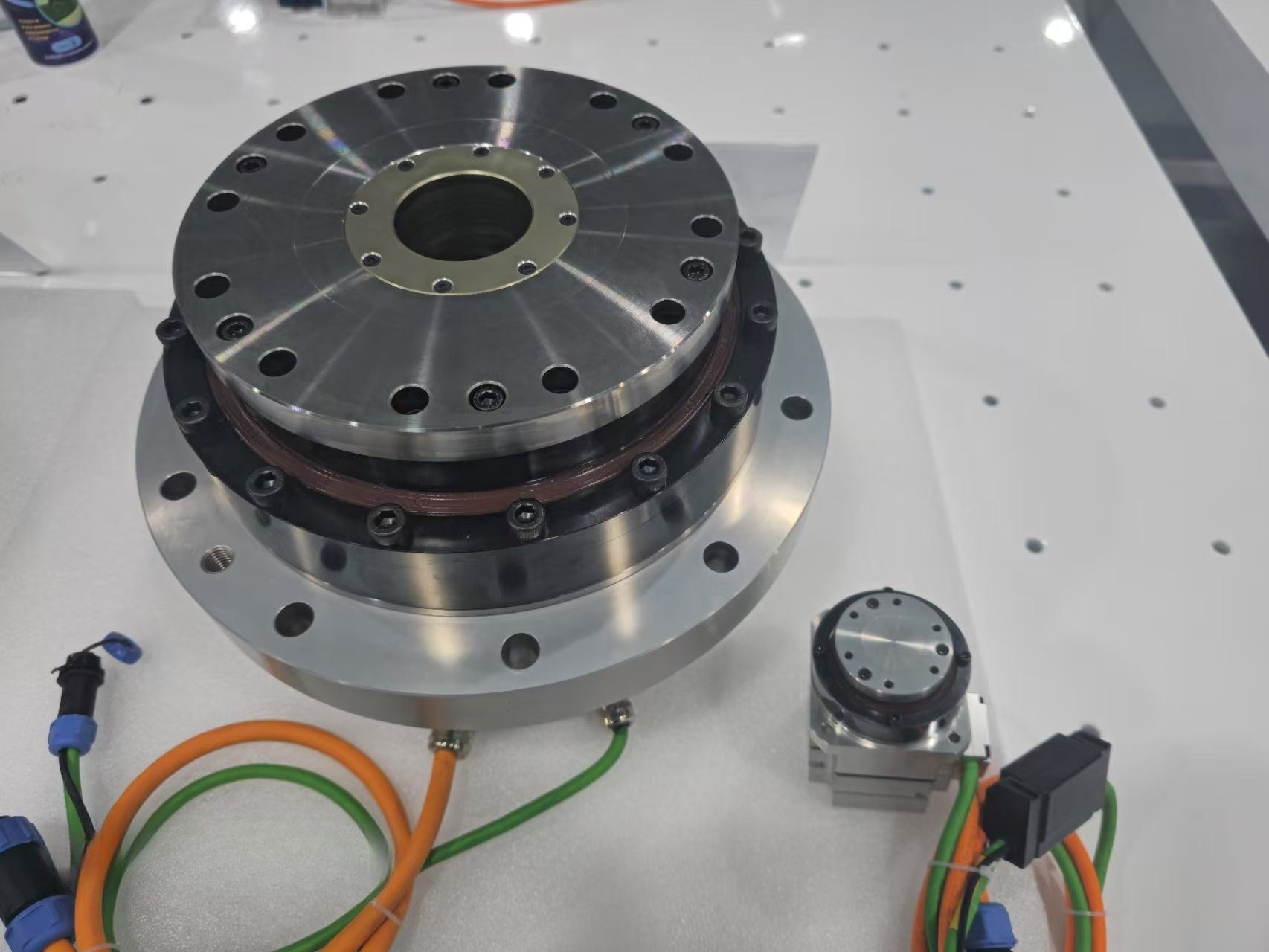

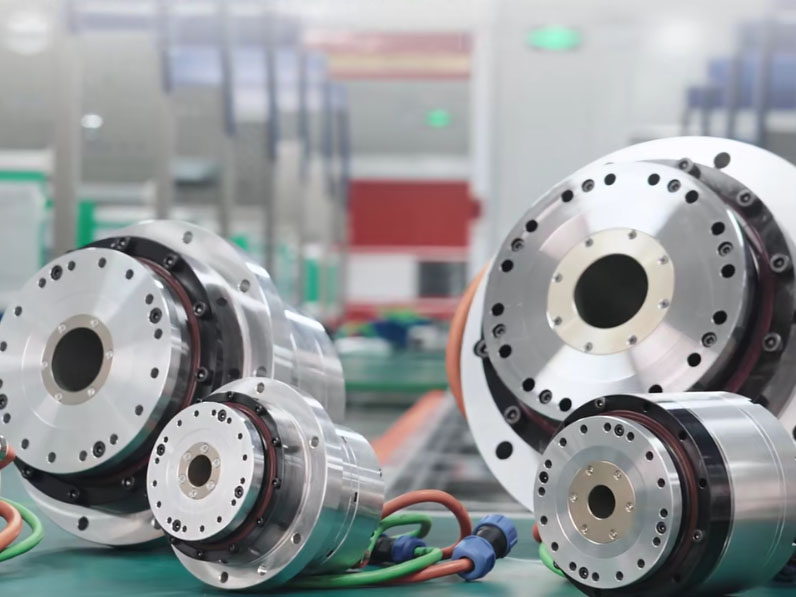

Harmonic Drive Joint

In industrial handling and high-load applications, the harmonic joint is virtually irreplaceable. It offers both high torque and high-precision control, enabling fine and smooth movements. This makes it the preferred joint module for high-end humanoid robots.

Planetary Reducer Joint

Due to its durability and impact resistance, the planetary reducer joint is commonly used in entertainment robots. Its robust structure provides better resistance to shock and overload compared to harmonic reducers, making it less prone to damage from sudden impact.

Cycloidal Reducer Joint

The cycloidal reducer joint features high rigidity and strong impact resistance, making it suitable for special industrial applications and experimental robotic systems. However, due to its lower precision, higher cost, and heavier weight, its market share remains relatively low at present.

| Joint Module Features | Harmonic Drive | Planetary Reducer | Cycloidal Drive | Comparative Analysis and Explanation |

| Core Advantages | High precision, zero backlash, ultra-compact | High rigidity, cost-effective, high efficiency | Ultra-high overload capacity, extremely long lifespan, high rigidity | Harmonic drives pursue ultimate precision and compactness, planetary reducers offer balanced reliability, while cycloidal drives prioritize maximum torque and robustness. |

| Precision & Backlash | Excellent (≤1 arc-min) • Multiple tooth engagement with excellent error averaging • Zero backlash, ultra-high positioning accuracy | Good (3–10 arc-min) • Accuracy depends on machining and assembly • High-precision versions are more expensive | Very good (1–3 arc-min) • Multiple tooth engagement with good averaging • Small backlash possible | Harmonic drives dominate in precision and are the undisputed choice for high-end humanoid robots. |

| Transmission Efficiency | High (80–90%) • Some hysteresis loss due to flexspline deformation | Very high (90–97%) • Gear meshing transmission • Efficiency drops with multi-stage designs | High (85–95%) • Rolling friction between cycloidal disc and pins ensures good efficiency | Planetary reducers generally provide the highest efficiency, making them ideal for energy-saving applications. |

| Lifespan & Durability | Moderate (7,000–10,000 hrs) • Limited by flexspline fatigue • High lubrication and cleanliness requirements | Long (20,000–30,000 hrs) • Depends on gear and bearing wear • Gradual, predictable wear | Extremely long (50,000+ hrs) • Rolling contact minimizes wear • Often considered “maintenance-free” | Cycloidal reducers have an overwhelmingly longer lifespan, while harmonic drives are limited by flexspline fatigue life. |

| Impact & Overload Resistance | Poor (2–3× rated torque) • Sensitive to shock and overload | Good (3–5× rated torque) • Strong structure, good overload capacity | Excellent (5–10× rated torque) • Outstanding shock and overload resistance | Harmonic drives must be carefully protected from impact in design, whereas cycloidal reducers are highly shock-resistant. |

| Size, Weight & Ratio | Excellent • Smallest, lightest, highest power density • High single-stage ratio (50–160) | Moderate • Medium size/weight • Small ratio (3–10), multi-stage for high reduction | Good • Compact but heavier • Medium-to-high single-stage ratios (30–100+) | Harmonic drives are unrivaled in lightness and compactness, serving as the ultimate solution for space-constrained designs. |

| Torsional Rigidity | High • Fast response, slightly weaker radial stiffness | High • Symmetrical design, good torsional rigidity | Very high • Highest rigidity, excellent deformation resistance

| All three types offer good rigidity, with cycloidal reducers slightly superior; harmonic drives require attention to radial load capacity. |

| Vibration & Noise | Low • Smooth and quiet, may resonate at specific speeds | Moderate • Depends on machining precision | High • Eccentric motion generates more noise | Harmonic drives perform exceptionally well in smoothness and noise reduction. |

| Cost | High • Complex manufacturing, most expensive | Low • Mature production, highly cost-effective | Medium • Complex structure, moderate cost | Planetary reducers have an absolute advantage in cost, while harmonic drives command a premium for their superior performance. |

Comprehensive Parameter Comparison

Harmonic vs Planetary vs Cycloidal Reducer Joints

To help customers choose the most suitable robot joint module, the HONPINE technical team has compiled a detailed parameter comparison table.

However, we still recommend contacting us for further guidance and customized selection based on specific application needs.

With the rapid growth of humanoid robots, entertainment robots, and collaborative robots, the demand for harmonic joint modules and planetary joint modules has surged.

HONPINE is continuously enhancing factory production and management while actively developing and testing cycloidal reducer joints to meet future market demands.