EtherCAT vs. CAN for Harmonic Drive Motors: A Technical Comparison

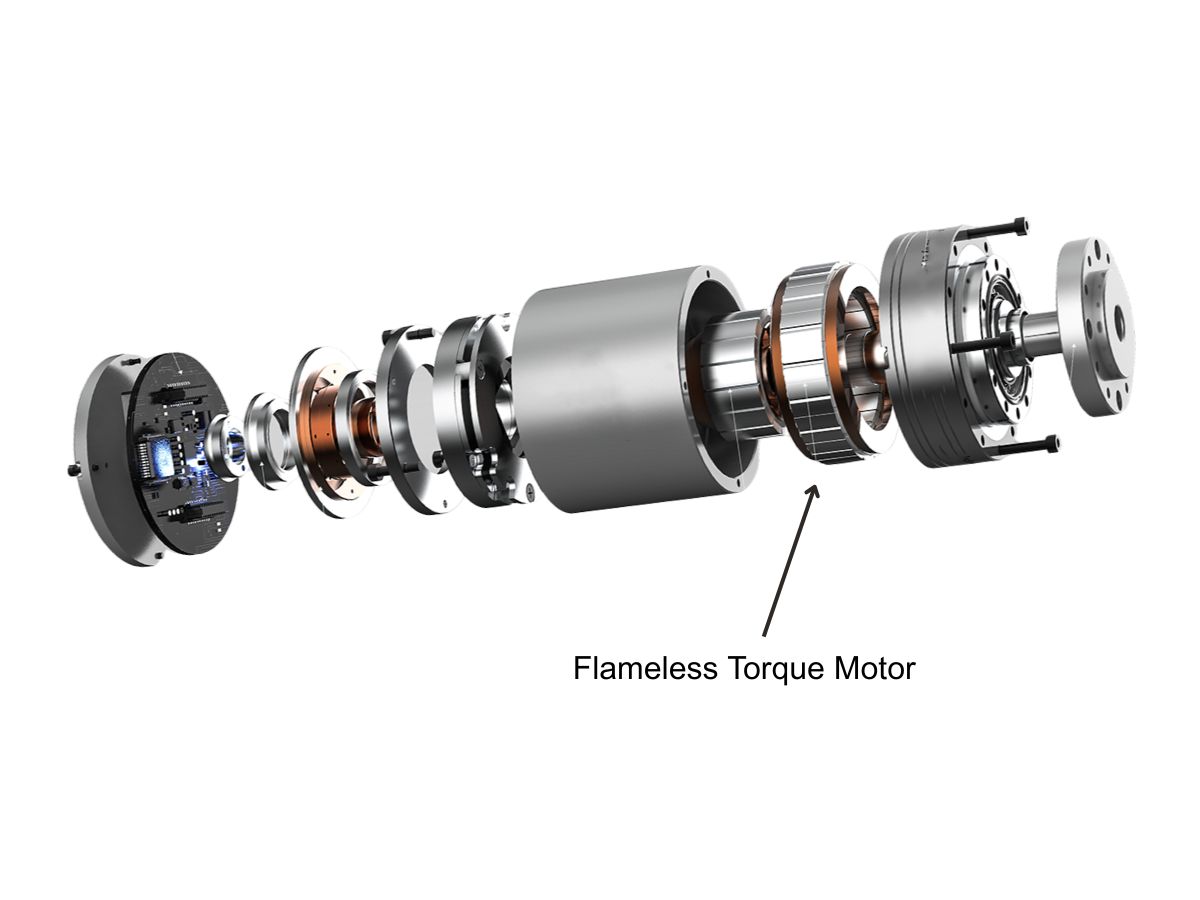

In the operation of robotic harmonic drive motors, the communication protocol serves as a critical link ensuring stable collaboration among core hardware components. EtherCAT and CAN are the two mainstream choices, with significant differences in performance that directly impact the control precision and response efficiency of harmonic drive motors.

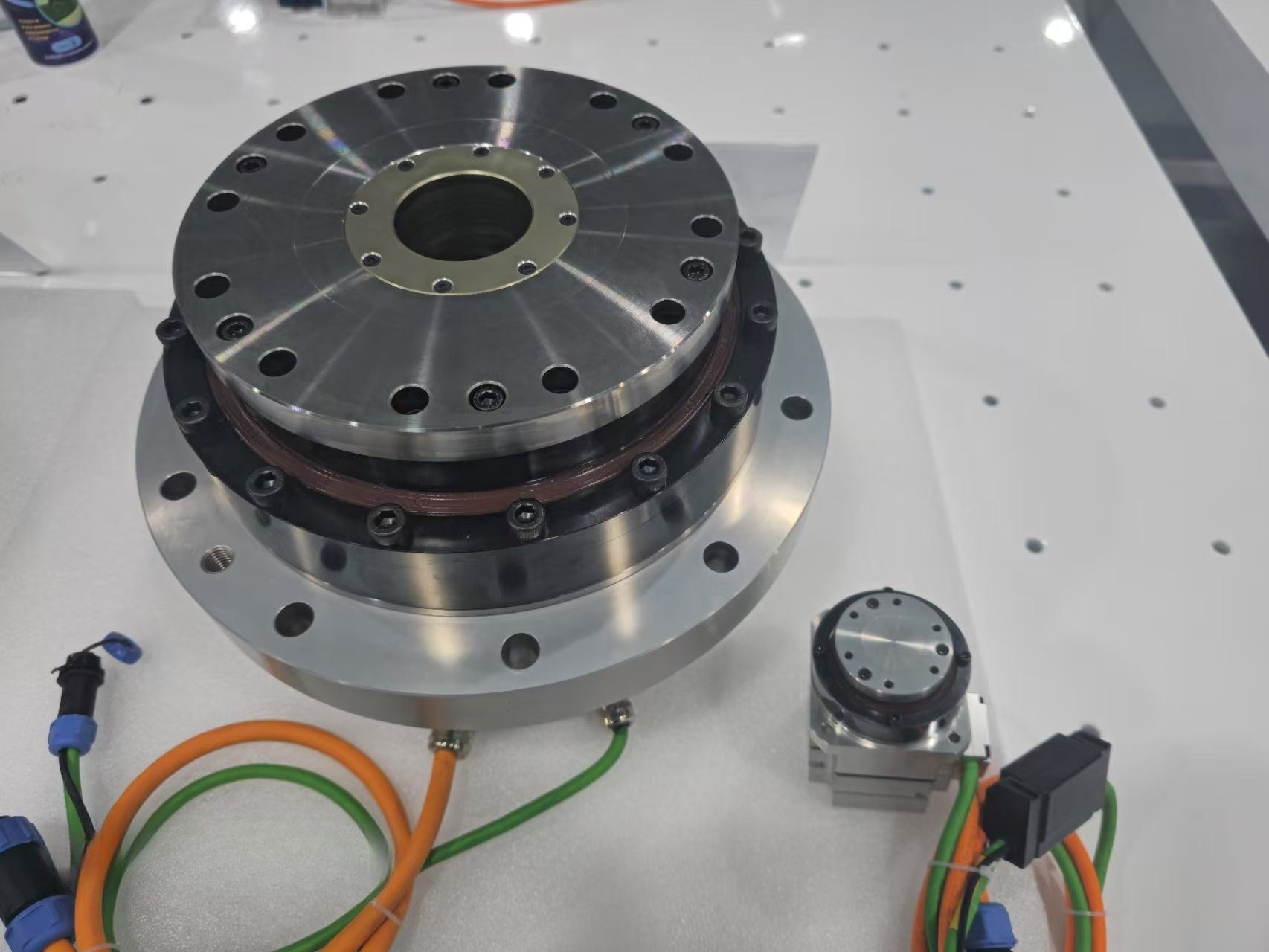

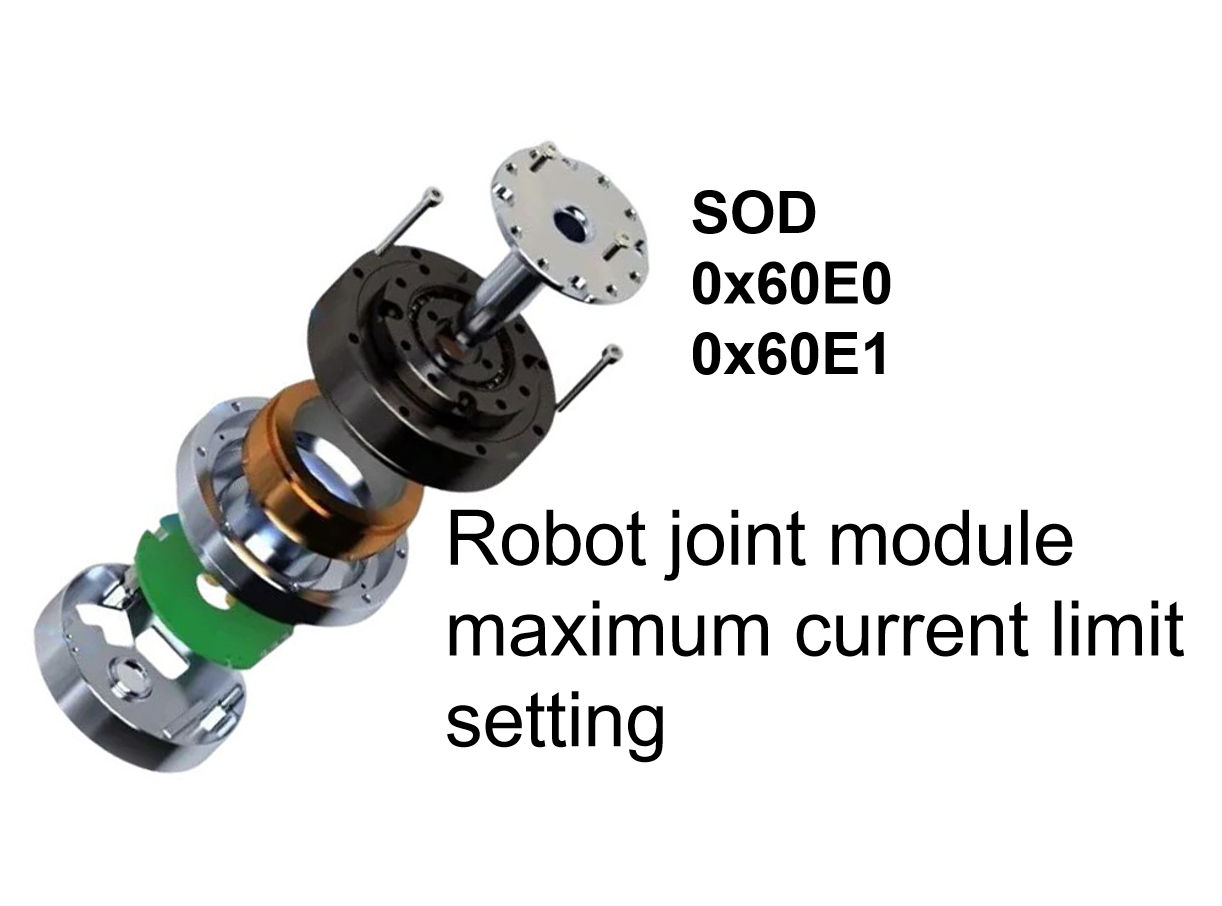

Harmonic Drive Motor with CAN Protocol

In terms of communication speed, the maximum rate of the CAN protocol is 1 Mbps. This speed meets basic requirements in small to medium-scale applications but reveals performance bottlenecks when dealing with multi-motor coordinated control. For instance, in an application with 10 motors, the CAN communication cycle typically operates around 500 Hz. However, influenced by factors such as communication content complexity and packet transmission uniformity, this cycle cannot be guaranteed stable and may fluctuate, thereby affecting the motion synchronization of harmonic drive motors.

Furthermore, the CAN protocol employs a "Carrier Sense Multiple Access with Collision Detection" (CSMA/CD) mechanism. As the number of devices on the bus increases, the probability of data transmission collisions rises. This not only extends the communication cycle but may also lead to data loss, posing certain operational risks for harmonic drive motors that require precise control. In terms of wiring and cost, while CAN supports a bus topology that simplifies wiring, its transmission distance is limited at high speeds (typically not exceeding 40 meters). If covering a large robotic system requires additional repeater devices, the overall cost may conversely increase.

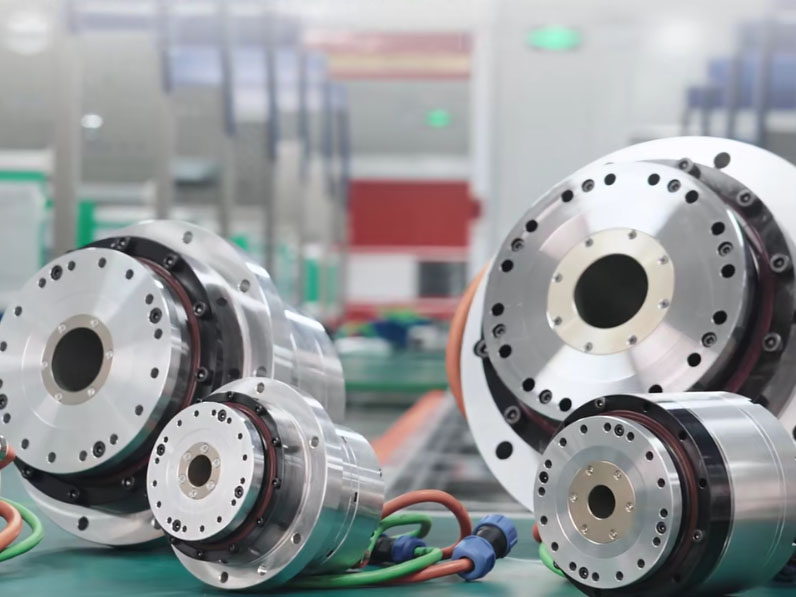

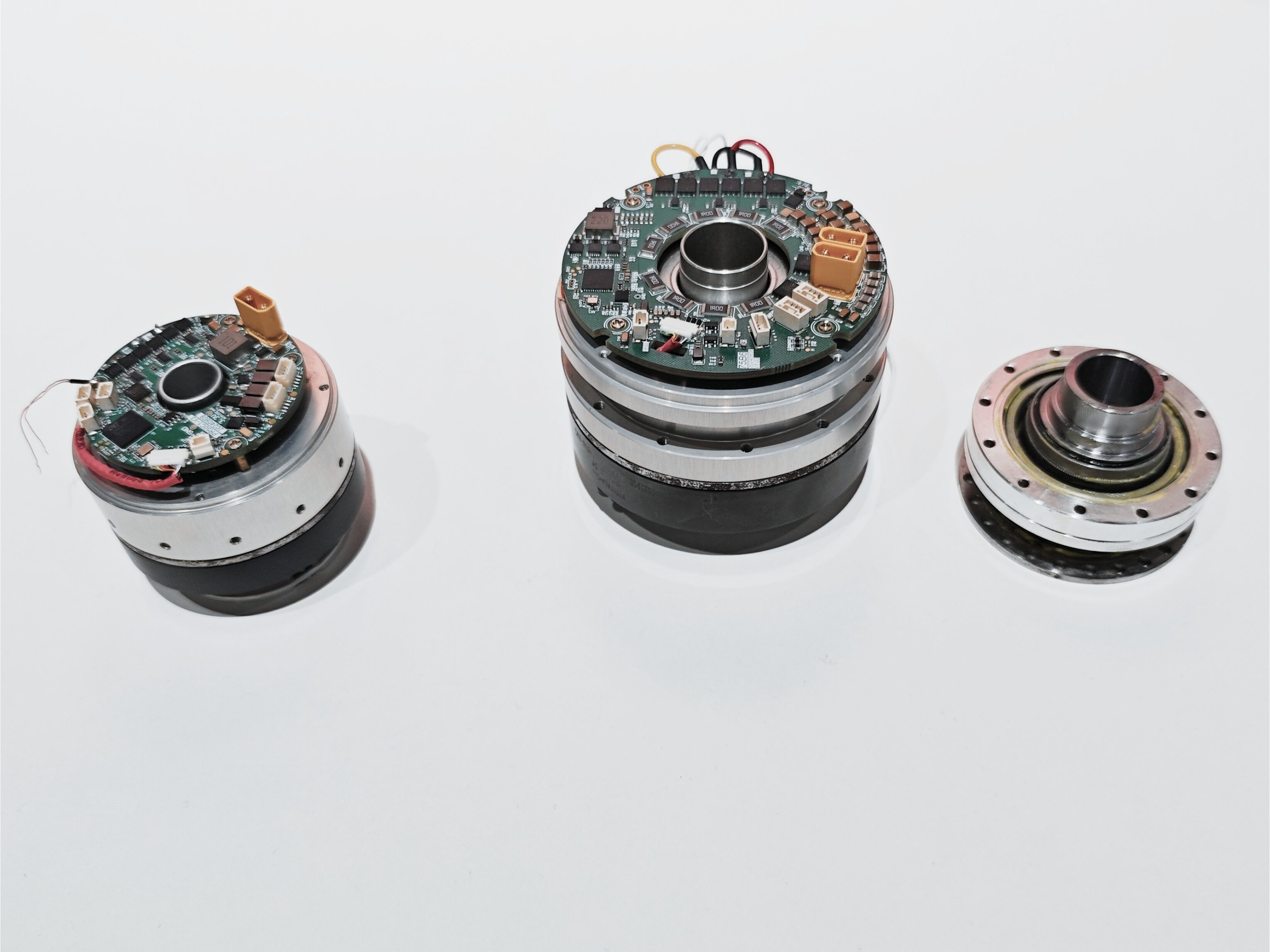

Harmonic Drive Motor with EtherCAT Protocol

In contrast, the EtherCAT protocol demonstrates stronger performance advantages. Its fixed communication rate of 100 Mbps is 100 times faster than CAN, providing a solid foundation for high-speed data transmission. Regarding communication cycles, EtherCAT supports up to 4 kHz in CSP/CSV/CST modes, far exceeding CAN's 500 Hz, enabling faster command response for harmonic drive motors. More notably, EtherCAT utilizes "Distributed Clock" synchronization technology, ensuring time deviations among all slave devices (motor drive modules) are controlled at the microsecond level through precise clock calibration. Even in tests with over 40 motors connected, it stably maintains a 4 kHz communication cycle, perfectly resolving synchronization issues in multi-motor coordination.

In terms of real-time performance, EtherCAT does not rely on traditional "store-and-forward" data packet transmission but uses "processing-on-the-fly" technology to complete data interaction directly during data frame transmission, significantly reducing latency. Even with an increase in the number of devices on the bus, transmission efficiency is not noticeably affected. For wiring, EtherCAT supports various topologies such as star and bus, with transmission distances up to 100 meters without repeaters. This adaptability to large robotic systems reduces the need for additional equipment, offering better long-term cost advantages. Moreover, EtherCAT possesses stronger anti-interference capabilities. Through differential signal transmission, it effectively resists electromagnetic interference in industrial environments, ensuring stable operation of harmonic drive motors under complex working conditions. This is crucial for high-precision robots such as collaborative robots and assembly robots.

In the field of high-end robotics, harmonic drive motors with EtherCAT have become the absolute mainstream choice due to their excellent real-time performance and high bandwidth. They effectively solve the challenges of high-speed real-time communication, precise power transmission, and accurate torque output. The CAN bus is more commonly used in applications with lower performance requirements or as an auxiliary communication network.

Double Click

Products Catelog