Brushless Motor is an Important Component of Robot Joint Module

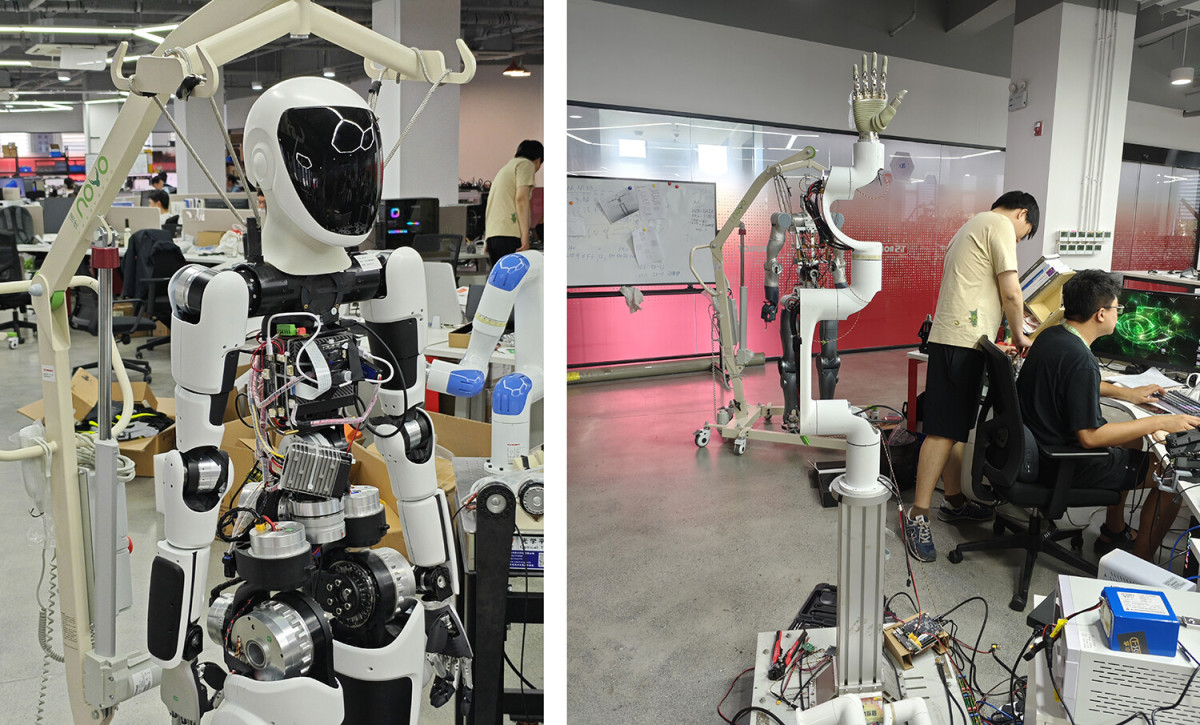

As manufacturing technology rapidly advances toward digitalization and intelligence, the robotics industry continues to evolve, introducing innovations that enhance automation in various fields. From household cleaning robots and industrial robotic arms to specialized welding robots and advanced legged robots, these machines are becoming increasingly integral to daily life and production. At the core of robotic systems, robot joint motors, harmonic reducers, and drivers stand out as the most critical components.

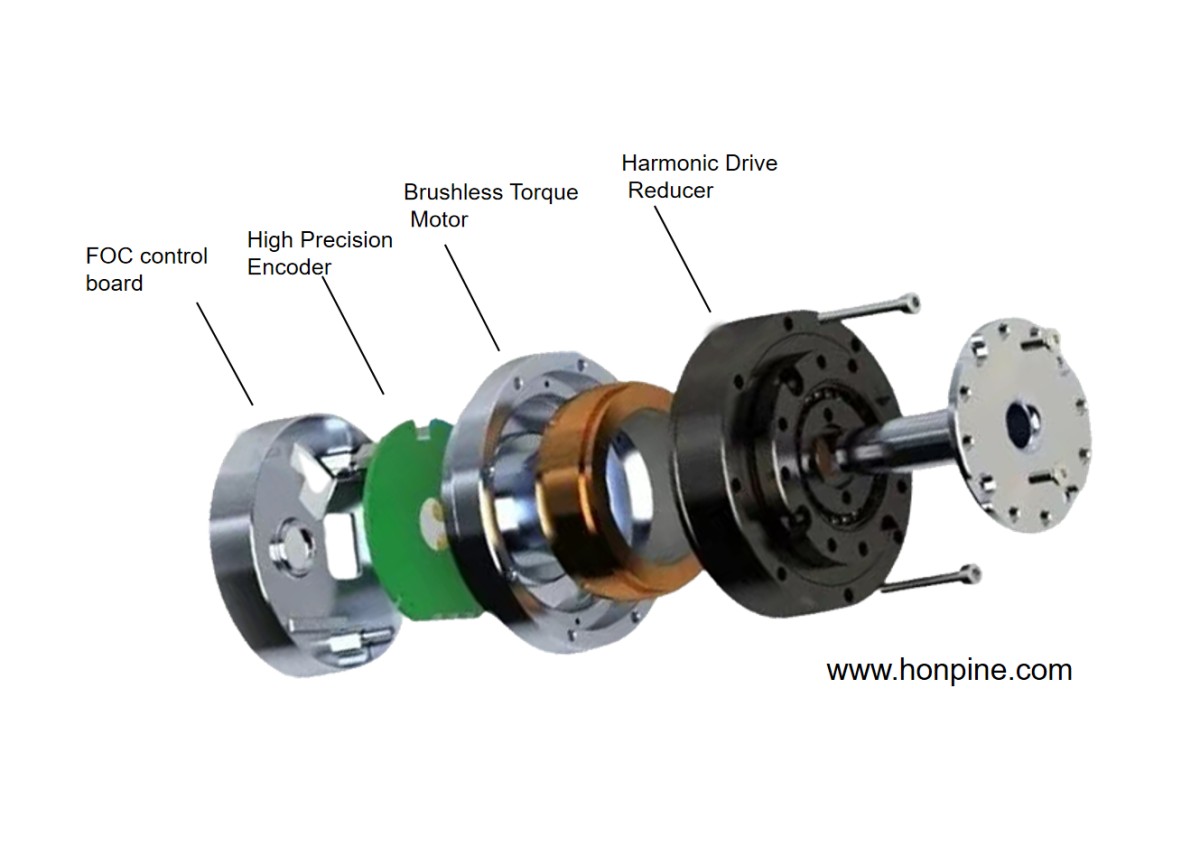

Integrating the motor, control circuits, and sensor modules into a unified system enhances efficiency, flexibility, and reliability. Research into joint motor modules enables more streamlined robot design, allowing for modular reuse, simplified system integration, and reduced development time and costs. This approach ensures greater adaptability and easier maintenance.

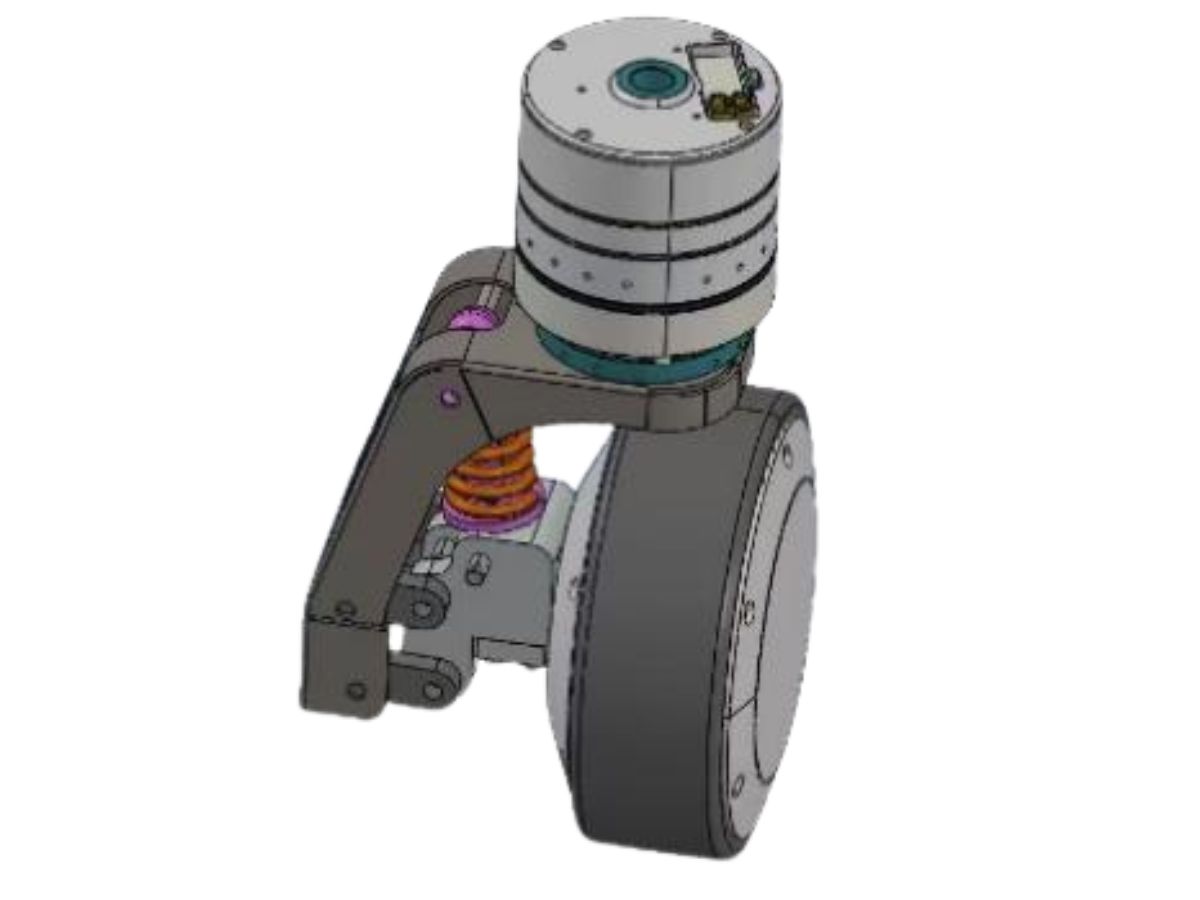

Within a robot's "body," the joint module acts as a vital "joint," and the brushless torque motor serves as its key "heart." Typically, these motors are brushless (though stepper or servo motors may also be used), with frameless torque motors being particularly notable for their high diameter-to-length ratio and increased number of magnetic poles.

Why Brushless Motors Excel in Joint Modules

Brushless torque motors operate using rotor position sensors to detect magnetic pole orientation, relaying signals to the controller. The controller processes these signals, triggering the inverter’s power switches to energize the stator windings, generating the necessary torque. This sophisticated control system enables multiple functions:

Precise motor control (forward/reverse rotation, braking)

PWM-based voltage regulation for open-loop speed control

Closed-loop speed and current regulation to optimize dynamic and static performance

Fault protection (e.g., short-circuit and overcurrent safeguards) for stable operation

The permanent magnet brushless DC frameless torque motor is distinguished by its frameless design. Unlike traditional motors, it eliminates the shaft, bearings, housing, and end covers, retaining only the rotor and stator. The rotor—typically an inner ring with permanent magnets—mounts directly onto the machine shaft, while the stator, composed of laminated steel and copper windings, integrates into the machine housing. This compact design maximizes space efficiency, a crucial advantage for space-constrained robotic joints.

Brushless Torque Motors Applications in Robotics

Today, brushless torque motors are widely adopted in robotic joints, enabling:

Humanoid robots to achieve lifelike limb movement

Collaborative robots (cobots) to perform high-precision tasks like assembly

Exoskeleton robots to assist users with mobility challenges

As the core of robotic joint modules, brushless torque motors drive technological progress, empowering robots to excel across diverse applications. Their unique advantages—compactness, precision, and reliability—continue to expand the possibilities of robotic innovation.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand